- Screens and Fine Screens- ROTAMAT Screens

- Screens and Fine Screens- Perforated Plate and Bar Screens

- Screens and Fine Screens- Step Screen

- Screenings Treatment

- Conveyor

- Membrane Filtration (MBR)

- Grit Separation and Treatment- Longitudinal Grit Traps

- Grit Separation and Treatment- Circular Grit Traps

- Micro Screening / Filtration

- Micro Screening / Filtration- Microscreens

- Sludge Treatment- Sludge Screening

- Sludge Treatment- Sludge Thickening

- Sludge Treatment- Sludge Dewatering

- Storm & Sewer Equipment- Combined Sewage Screens

- Storm & Sewer Equipment- Pumping Station Screens

- Sludge Treatment - Sludge Drying

Huber SE products

Screens and Fine Screens- ROTAMAT Screens

Huber ROTAMAT - Model Ro 1 - Fine Screen

The HUBER Fine Screen ROTAMAT® Ro1 is completely made of stainless steel and acid treated in a pickling bath. These screens are either installed directly into the channels, or are supplied as tank-mounted units, with an inclination of 35°. The wastewater flows into the open end of the inclined screen basket and then through the screen. Floating and suspended materials are retained by the bars of the screen basket. Blinding of the screen surface generates an additional filtering effect so that solids can be retained that are smaller than the bar spacing.

Huber ROTAMAT - Model Ro2 / RPPS / STAR - Rotary Drum Fine Screen / Perforated Plate Screen

The HUBER ROTAMAT Rotary Drum Fine Screen / Perforated Plate Screen operation is based upon a unique system that allows combination of screening, washing, transport, compaction and dewatering in a single unit.

Screens and Fine Screens- Perforated Plate and Bar Screens

HUBER EscaMax - Belt Screen

The EscaMax® complements the well-known HUBER program for municipal and industrial wastewater screening, as it is particularly well suited in situations where excellent separation efficiency is required in deep channels with high water levels.

Screens and Fine Screens- Step Screen

Huber - Model SSV - Vertical Step Screen

The STEP SCREEN® System is widely accepted and successful due to its function and easy-to-follow operation principle as well as the simple cleaning method without any aids (self-cleaning effect according to the counter-current principle). It is furthermore easy to maintain and able to handle extremely big screenings volumes whilst it also offers a high operational reliability. The motor linkage drive has been developed from the well-proven and patented link system. To the benefit of our customers we intentionally avoided difficult-to-maintain chain drives. With the linkage type we are able to master the occurring bending moments on the lamellas, especially with high water levels.

Screenings Treatment

HUBER - Model WAP SL - Wash Press Screenings Treatment Systems

The WAP SL operates in a batch mode. Screenings either drop into the launder tank directly from a screen or conveyor, or they are flushed into the tank through a launder channel. After a batch of screenings has been fed, the tank is filled up with wash water and agitated for an adjustable period by means of an impeller. The fecal matter is loosened and removed from the screenings by high turbulence and shear. After the washing cycle has been finished, an automatic valve opens and the wash water drains through perforations in the trough. It returns, together with the fecal matter, to the wastewater flow. A screw in the trough conveys the screenings towards the mouth of a tube whereby they are, as an additional option, rinsed with spray water. The screw pushes the screenings through the pressure zone where they are compressed, dewatered and compacted before they are finally discharged through the discharge pipe into a dumpster or bagger.

Conveyor

Model Ro8 / Ro8 T - Screw Conveyor

Our customized designed and manufactured HUBER Screw Conveyors are supplied as closed tube or trough version, depending on the requirements. They are installed for horizontal, inclined and even vertical transport of screenings, dewatered sludge, grit etc. from wastewater treatment plants, or other solids from industrial processes.

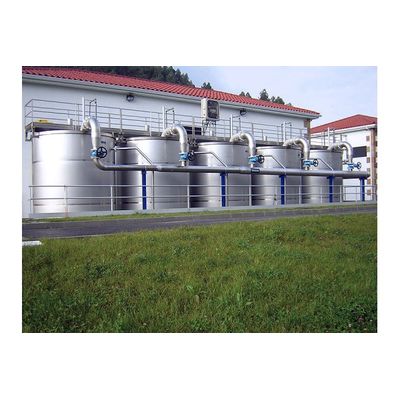

Membrane Filtration (MBR)

HUBER - Model VRM - Membrane Filtration System

The HUBER VRM® process is a system of ultrafiltration membranes submerged within the aeration tank. The resultant high effluent quality meets the most stringent regulations whilst also allowing for the capacity to meet the increasing and higher disposal legislation anticipated in the future, with optimised investment and operating costs.

Grit Separation and Treatment- Longitudinal Grit Traps

Huber ROTAMAT - Model Ro6 - Longitudinal Grit Trap

The grit trap design and dimensioning are fully compliant with international standards. The ROTAMAT® Ro6 is available as an aerated or unaerated unit. The decision on when to use the aerated or unaerated option is for example the specific ratio between the storm and dry weather flow and if any further grit treatment facilities are installed or planned.

Grit Separation and Treatment- Circular Grit Traps

Huber - Model HRSF - Circular Grit Trap

Separation of the grit particles in the HUBER Circular Grit Trap HRSF is supported by the rotational motion of the wastewater. The separation effect is generated by overlapping of the vertical downward motion and a developing centrifugal force acting on the individual grit particles. The inner tank surface serves as the separation area.

Micro Screening / Filtration

Huber CONTIFLOW - Sandfilter

Continuous deep bed filtration with sand bed heights between 1 and 2 meter fulfils the high requirements on effluent quality. In combination with a physical/chemical treatment stage (precipitation/flocculation) also dissolved material (e.g. orthophosphate) iscarried over into the solid phase and separated in the filter. Colloidal material is agglomerated to filterable material is flocculated to filterable material.