- Home

- Companies

- Hudson Industries

- Products

Hudson Industries products

OWS/ Oil Water Separators

Hudson Industries - Coalescing Oil Water Separator

Hudson Coalescing Oil Water Separator Flowrates 1 to 5000 GPM As low as 10 ppm oil in water concentration Efficiently remove free-floating oil, grease and settleable oily coated solids from oil/water discharges. __ All separators are constructed to API specifications. #oilwaterseparator #hudsonind #oilskimmer #cleanwater #madeinamericaOil Water Separators

Flow rate to 20,000 gpm • Integrated sludge handling systems • Can operate in 20øF conditions with tank heating

OWS / Condensate Separators

Effective Free Oil Separation, as Low as 10mg.l @20 microns. Heavy Duty Steel Construction. No Costly Filter Elements to Replace. High Efficiency Coalescing Module. Simple Installation. Suitable for all Petroleum Based, Non-Synthetic Oils.

Corrugated Plate Interceptor (CPI)

For treatment of process, run-off, ballast/bilge, and oily water. Flow rates from 25-8000 gpm. Capable of handling 100% oil slugs on limited basis. Carbon Steel/SS Construction. Corrugated plate of PVC,CPVC,PE,SS. Pump skids available. Can be designed with heaters for extreme cold. Equipped with slotted pipe, adjustable weirs or API rotary skimmers. Corrosion resistant to NACE MR0175.

Atmospheric Aspirated Pumps

Capacities from 1gpm-8000 gpm. Available in Pressurized and Atmospheric Systems. 95-99% Efficient. Unique Removable Rotor Assembly. ASME Stamped `U` Available. Variable Speed Range. Direct Drive. Explosion-Proof Packages Available.

Pressurized Rotor

Specifications: Capacities from 1gpm-8000 gpm. Available in Pressurized and Atmospheric Systems. 95-99% Efficient. Unique Removable Rotor Assembly. ASME Stamped `U` Available. Variable Speed Range. Direct Drive. Explosion-Proof Packages Available.

Atmospheric Coalescing Separators

Specifications: Capacities from 1 gpm-8000 gpm. Gravity and Coalescing Systems. Few Moving Parts. API and AWS Design & Construction. Broad Range of Skimmers. Media Available in a Variety of Materials.

Anionic and Cationic Polymers for Separation Processes

We offer a range of emulsion breaking and flotation aid chemicals,fully integrated with Hudson Industries` separation equipment. Custom designed for your application. Anionic and cationic polymers. Metal precipitants. Flocculants. Adsorbents. Custom blended products.

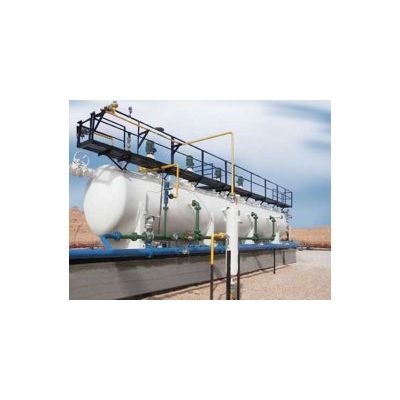

Two/Three Phase Separation Units (TPS)

10-10,000 gpm. Previously Approved Designs by Lloyd?s Veritas, Bureau Veritas, Norsk Veritas. Operating Pressures to 3,000 psi. ASME `U` Stamp Vessels. Explosion Proof Design. Externally Adjustable Skimmers. Media Available in a Variety of Materials. Broad Range of Vessel and International Materials. Optional Solids Handling Packages.

Pressurized Aspirated Pumps

Capacities from 1gpm-8000 gpm. Available in Pressurized and. Atmospheric Systems. 95-99% Efficient. Unique Removable Rotor Assembly. ASME Stamped `U` Available. Variable Speed Range. Direct Drive. Explosion-Proof Packages Available.