Hunan Unique Steel Pipe Co.,Ltd products

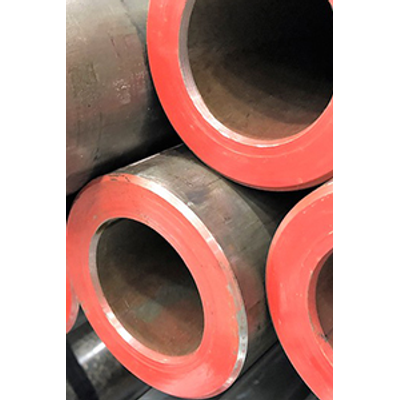

Seamless Steel Pipe

Unique - Seamless Steel Pipe

Specifications : Range. Out Diameter : 1/4 inch-36 inch. Wall Thickness : 1.25 mm-50 mm. Length : 3.0m-18m.

Unique - Structural Tube

Specifications: Range. Out Diameter: 1-1/4"-16". Wall Thickness: 0.109"-0.562". Length: 3.0m-18m.

Unique - Steel Fluid Pipe

Specifications Range: Out Diameter: 19.05-168.3mm. Wall Thickness: 2.31-14.27mm. Length: 3.0m-18m.

Unique - Steel Industrial Pipe

Specifications Range: Out Diameter: ¼" to 26". Wall Thickness: 20, 30, 40, STD, XH, 80, 100, 120, 140, 160, XXH. Length: 3.0m-18m.

ERW Steel Pipe

Unique - Electric Resistance Welded (ERW) Steel Pipe

ERW (Electric Resistance Welded ) Steel Pipe, HFW (High-Frequency Welding) Steel Pipe. Specifications Range: Out Diameter: 1/8 inch to 24 inch. Wall Thickness: max 26.5mm. Length: 3.0m-18m.

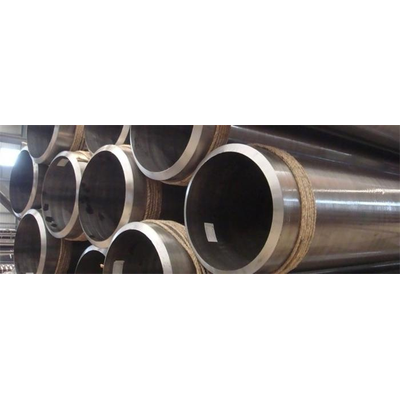

LSAW Steel Pipe

Unique - Model LSAW - Steel Pipe

Specifications Range: Out Diameter: 219mm-720mm(UOE),406mm-1625.6mm(JCOE). Wall Thickness: max 65mm. Length: 3.0m-18m.

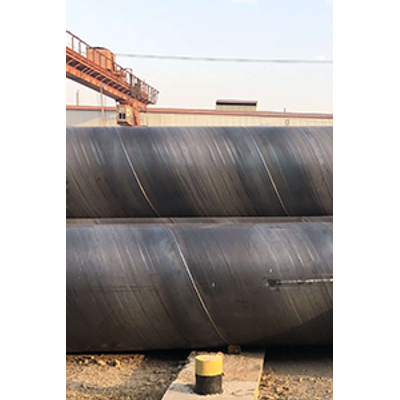

SSAW Steel Pipe

Unique - Model SSAW - Steel Pipe

Specifications Range: Out Diameter: 219mm-3520mm. Wall Thickness: 3mm-25mm. Length: 3.0m-18m.

Stainless Steel Pipe

Unique - Stainless Seamless Pipe

Seamless Stainless Steel Pipe. Standards: ASTM A312,ASTM A358,ASTM A813,ASTM A814. 300 Series Stainless Steel Grades: 304 – 304/L – 304H – 309/S – 309H – 310/S – 310H – 316L – 317L – 321 – 321H – 347 – 347H. 400 Series Stainless Steel Grades: 410. Nickel Alloy Grades: Alloy 20 – 200 – 400 – 600 – 601 – 625 – 825H – 825HT – C276.

Unique - Welded Stainless Pipe

Standard: ASTM A240,ASTM A312,ASTM A358,ASTM A778. 300 Series Stainless Steel Grades: 304 – 304/L – 304H – 309/S – 309H – 310/S – 310H – 316L – 317L – 321 – 321H – 347 – 347H . 400 Series Stainless Steel Grades: 410 – 410S . Nickel Alloy Grades: Duplex 2205, Duplex 2507. Welded Stainless Steel Pipe Tolerances.

Alloy Steel Pipe

Unique - Alloy Steel Pipe

Alloy steel pipes are known to deliver exceptional performance and are generally developed for meeting the demands: Energy-related applications that involve Oil and Gas Drilling. Catering to domestic or industrial needs. In conveyance of fluids intended for critical high temperatures. In general corrosion service applications. In heat transfer process equipment like Boilers, Heat Exchangers. In General Engineering and Process Instrumentation applications.