Hydro Flo Technologies LLC products

Chemical Reaction Systems

HydroFlo Tech - Chemical Reaction Systems

The HydroFlo chemical reaction systems are designed to deal with a myriad of water and wastewater treatment issues. Whether your application calls for a basic pH adjustment system or a complex multi-stage reaction system, HydroFlo can supply a system that will meet your process requirements.

Clarifiers

ClariMax - Inclined Plate Clarifiers

The HydroFlo ClariMax inclined plate clarifier is a unique device in the world of clarification equipment. Our experience in clarifier design, and recent advancements in fluid dynamic modeling, have all been applied to make the HydroFlo ClariMax the most efficient clarifier available today.

Stinger - Model LS Series - Inclined Plate Clarifiers

The HydroFlo LS Series Inclined Plate Clarifier is designed to meet the needs of low volume industrial waste generators. The LS series clarifier is designed and configured to supply you with the most cost efficient design in the market today.

Control Panel

NEMA - Model pH-1.0 - Industrial Duty pH Control Panel

This basic panel includes all the functions required for controlling the pH of a waste stream. It accepts inputs from a pH sensor which controls two outputs. The standard setup is one chemical metering pump with an alarm circuit. The system can be configured for two chemical metering pumps as an option (metering pumps and pH sensor sold separately). The panel comes complete with a mixer control circuit and a lockable main disconnect switch.

Dissolved Air Flotation Systems

HydroFloat - Dissolved Air Flotation Systems (DAF)

HydroFlo Tech` dissolved air flotation technology, or "DAF", is an effective, economical process for removing hard to separate suspended solids from wastewater and also for resolving overall water clarity issues. A dissolved air flotation (DAF) system resolves suspended solids and clarity issues by reintroducing a slip stream of treated water (from the system`s effluent) back to the system`s influent. This pressurized, recycled water is saturated with dissolved air. When the pressure is released at the system`s influent, the air comes out of solution on the surface of suspended solids particles throughout the dissolved air flotation (DAF) influent mixing chamber. As these billions of micro bubbles come out of solution, they float the suspended solids particle to the surface of the dissolved air flotation (DAF) separation chamber, where they are removed by a surface skimmer.

FloatPac - Inclined Plate Style Dissolved Air Flotation System

HydroFlo Tech` FloatPac series of dissolved air flotation systems, or "DAF", is an effective, economical process for removing hard to separate suspended solids from wastewater and also for resolving overall water clarity issues.

Media Filters

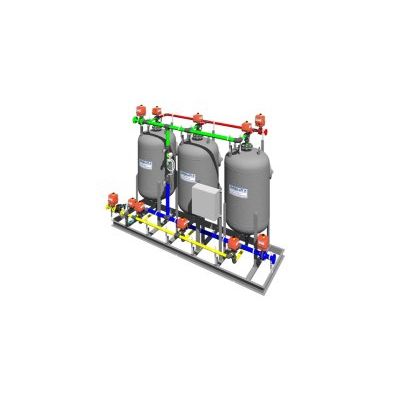

HydroCell - Automatic Backwashing Sand Media Filters

HydroFlo High Rate Automatic Backwashing Sand Media Filters are designed for general-purpose water filtration. These permanent media, automatic backwashing filters will remove organic and/or inorganic suspended solids down to 20 microns in size. Through the use of automatically controlled backwashing, the filter will operate “on line” for extended periods of time prior to the short backwashing cycle. Automatic filter operation is monitored on elapsed time, as well as pressure differential. When the controller “calls” for a backwash as a result of pressure differential or elapsed time, the backwashing function utilizes a portion of the clean filtered water produced by the system to clean the media. Single tank systems utilize unfiltered water for backwashing. Optional external backwash water sourcing systems are available for both single and multiple tank systems.

HydroCell - Deep Bed Automatic Backwashing Sand Media Filters

HydroFlo High Rate Automatic Backwashing Sand Media Filters are designed for general-purpose water filtration. These permanent media, automatic backwashing filters will remove organic and/or inorganic suspended solids down to 20 microns in size. Through the use of automatically controlled backwashing, the filter will operate “on line” for extended periods of time prior to the short backwashing cycle. Automatic filter operation is monitored on elapsed time, as well as pressure differential. When the controller “calls” for a backwash as a result of pressure differential or elapsed time, the backwashing function utilizes a portion of the clean filtered water produced by the system to clean the media. Single tank systems utilize unfiltered water for backwashing. Optional external backwash water sourcing systems are available for both single and multiple tank systems.

HydroCell - Automatic Backwashing Sand Multi Media Filters

HydroFlo High Rate Automatic Backwashing Sand Media Filters are designed for general-purpose water filtration. These permanent media, automatic backwashing filters will remove organic and/or inorganic suspended solids down to 20 microns in size. Through the use of automatically controlled backwashing, the filter will operate “on line” for extended periods of time prior to the short backwashing cycle. Automatic filter operation is monitored on elapsed time, as well as pressure differential. When the controller “calls” for a backwash as a result of pressure differential or elapsed time, the backwashing function utilizes a portion of the clean filtered water produced by the system to clean the media. Single tank systems utilize unfiltered water for backwashing. Optional external backwash water sourcing systems are available for both single and multiple tank systems.

Media Packs Equipment

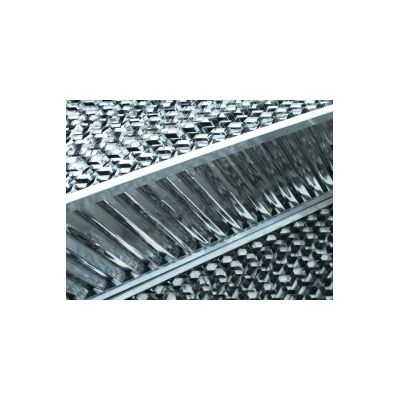

DynaPac - Cross Corrugated Media Packs Equipment

The HydroFlo Tech, DynaPac Cross Corrugated Coalescing Media is an effective media suitable for a number of different applications. Oil Water Separators: DynaPac™ Coalescing media is the industry standard for high efficiency oil water separators and separation systems. DynaPac™ coalescing media is ideal for new installations or replacement of existing media. Configurations are available for retrofitting any manufactures separator.