Idemag SL products

Magnetic Separation

Idemag - Eddy Current Separator

This equipment is designed to separate non-ferrous metals (aluminum, brass, copper) from the rest of the bulk stream. Taking into account that this type of metal does not interact with magnets, this separation is obtained creating a repulsive effect by rotating powerful neodymium magnets at high speed.

Idemag - Overband With Permanent Magnets

The magnetic “overband” separators are placed suspended on the conveyor belt that carries the bulk stream to be filtered. The overband is suitable for the extraction of all kinds of ferrous materials in various industries (recycling, mining, cement, chemicals, plastics, aggregates, etc.).

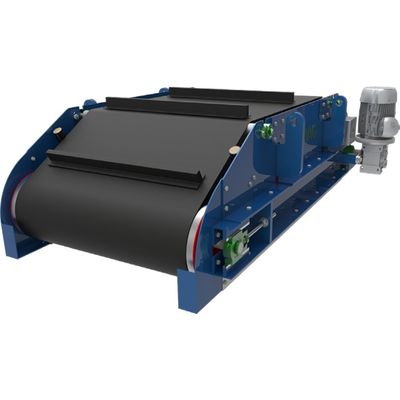

Idemag - Electromagnetic Overband Separators

The overbands separators with electromagnetic coil are especially suitable for continuous work that requires extra magnetic power. The electromagnetic field is higher to permanent magnets, which allows installing it at a greater distance from the material to be filtered. The situation on the conveyor belt is exactly the same as the system with permanent magnets. They are especially effective in many industries (recycling, mining, cement, plastics, aggregates, etc.). Our compact design is highly efficient in terms of coil cooling, avoiding any magnetic power loss due to heat. Each unit is designed according to each installation requirements. The magnetic system has a multitude of customized elements: electromagnetic coil power, physical measurements, conveyor belt type and type of drive fins, power and type of motor for traction, paint finishing, etc.

Idemag - Stainless Steel Magnetic Separator System

The stainless steel magnetic separator is made up of a high induction magnetic pulley, capable of attracting stainless material. The magnetic configuration and effectiveness of this model will depend on the type and composition of stainless steel to be treated. Our technical team must carry out an operation test using the material provided by the client. In the stainless steel magnetic separator, the most advanced technology in permanent magnets is used to obtain an ultra-powerful magnetic field. Optionally, they can incorporate a control panel with a frequency variator to adjust the speed parameters of the conveyor belt to the maximum. To increase the effectiveness of the stainless steel magnetic separator, the use of a vibrating feeder is recommended.

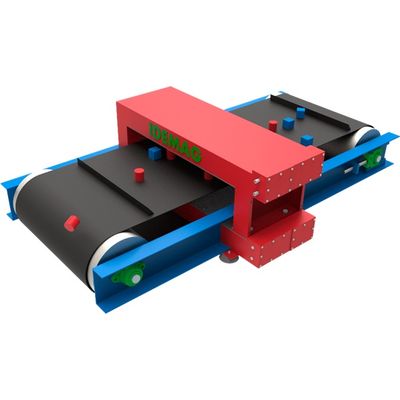

Idemag - Metal Detector for Electronic Device

The metal detector is an electronic device designed specifically for locating metal contaminants mixed with other products. Its function is to protect any industrial equipment (crushers, shredders, mills, laminators, etc…) that can be damaged by a metallic element.

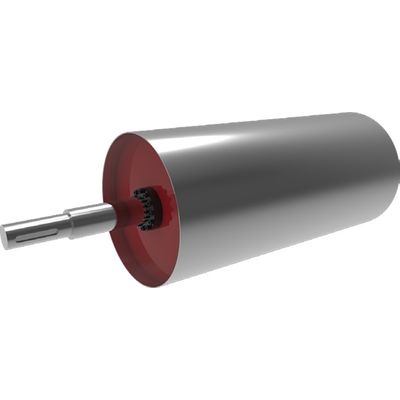

Idemag - Magnetic Pulley Separator

The magnetic pulleys are a highly efficient separation system to eliminate ferric contamination from many different materials as aggregates, granulated plastics, urban waste, etc. They are especially suitable for continuous work in demanding environments.

Idemag - Magnetic Plate Separator

The magnetic plate consists of a series of ferrite or neodymium magnets coated in stainless steel. This unit is placed suspended on the conveyor belt that carries the material to be treated. It is the most simple and economical solution for the separation of ferrous elements. Its use is recommended for installations with ferrous contamination and where the unit can be placed in accessible locations.

Idemag - Magnetic Humps

The magnetic humps are used for the removal of ferrous parts in industrial systems where the raw material falls freely by gravity. These magnetic separation equipments are adapted to both round and rectangular pipes. These magnetic separators are designed to remove from thin particles up to large pieces of ferrous contamination that circulate freely through the pipes. They provide uninterrupted protection and ensure product purity. It can be installed in industrial applications that work with granulated or powdered products, in humid or lumpy states.

Idemag - Magnetic Grids

Magnetic grids are designed using different magnetic bars configurations. The magnets are placed in round or rectangular pipes, preventing the passage of ferrous contamination. Especially suitable in production lines of grain o powder products.

Idemag - Magnetic Filter for Wet Products

The magnetic filter for wet products is especially indicated in the mining industry. The primary material reaches the magnetic separator in the form of sludge contaminated with iron particles. In a first step, the sludge is diluted with water and the product is subsequently processed using high induction magnets. The final drain results in a clean dissolution of ferrous contaminants and a mixture of water with the removed contaminants.