IDM Instruments Pty Ltd. products

Testing Instruments

IDM - Box Opening Pressure Tester

The Box Opening Pressure Tester measures opening force of flat stacked carton boxes. The instruments is uesful in the process of research and development. As well as the quality control during the production of cartons. Thereby, reducing risks and speeding up production set-up time.

IDM - Model IDM-C0056-M1 - Clicker Press

The Swing Arm Clicker Press is useful for a wide variety of die cutting applications. The most common uses are cutting soft to semi-rigid materials. For example, gaskets, leather, cork, rubber, elastic, foam, and other like materials. All of these cutting presses are completely hydraulic. And also strong casting material to ensure powerful yet quiet running. The Clicker Press casting also ensures maximum beam strength and performance. All moving parts are of hardened steel and are self-lubricating. There are many models available ranging from 8-25 tons with bed sizes up to 20"x40" and cutting heads up to 24" in width.

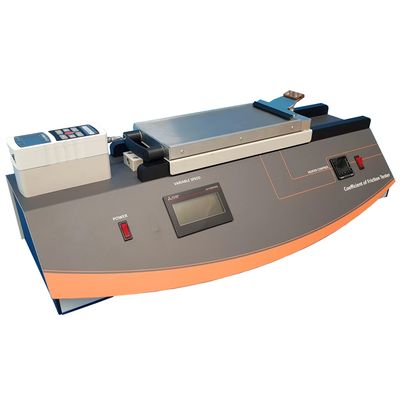

IDM - Model IDM-C0055-M3 - Coefficient of Friction Tester

Coefficient of Friction Tester with Variable Speed & Heated Platen is the latest. This instrument ensures a fast, reliable, and accurate method of determining the coefficient of friction. Thus, the Coefficient of Friction Tester with Variable Speed & Heated Platen is most efficient. Our range of COF Testers is used to determine the static and kinetic friction. For materials like plastic film, sheeting, paper, and other sheeted material coatings. Their small benchtop design makes it easy to use in a laboratory. Or even set up out on the production floor for offline testing.

IDM - Model IDM-F0031-M1 - Foam Porosity Tester

The Auto Foam Porosity Tester monitors the porosity of flexible cellular polyurethane. This machine determines how easy air passes through a cellular structure. These airflow values are an indirect measurement of certain cell structure characteristics. This model adheres to relevant international standards for measurement of a flexible cellular. That is 50mm x 50mm x 25mm.

IDM - Model IDM-G0002-M1 - Gelbo Flex Tester

Gelbo Flex Tester determines whether a certain plastic laminate material can withstand repetitive strain. It involves attaching sample pieces of plastic to the two circular clamping disks. This is via hose clamps. And then the machine twists and turns the specimen in specific movements. This process will show a visual result of pin holding. Thus, testing if the plastic can sustain the strain. If not, check plastic quality. this is usually useful within the plastic industry. The Gelbo Flex Tester has been designed to determine the resistance of flexible barrier materials to pin holing as stated in the ASTM F 392.

IDM - Model IDM-F0025-M1 - Universal testing Machine

The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing. The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD). Which is calculated by determining the force required to deflect a test piece. Which is a percentage of its original thickness using a circular indentor. This applies a force, while also recording the degree of indentation. As the name suggests, it is called "Universal testing Machine" because it can test tensile and compression of various materials. For example, textiles, rubber, springs, plastic and others. The tests conform with relevant testing standards such as ASTM, ISO, JIS, GB, and many others.