- Home

- Companies

- Illawarra Coatings

- Products

Illawarra Coatings products

Epoxy - Waterborne

EcoPoxy - Waterborne Epoxy Coatings for Concrete

EcoPoxy WB is a high performance two component water based industrial epoxy coating system available in a range of colours. EcoPoxy WB White is designed for floor and wall applications where durability and chemical abrasion resistance is required.

Epoxy - Solventfree

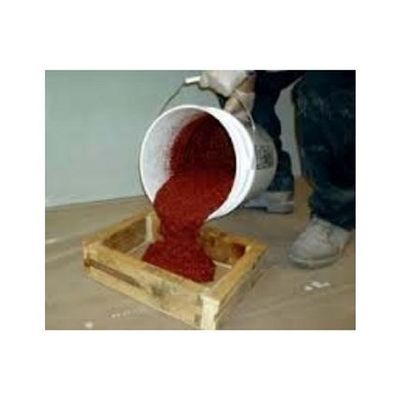

EcoPoxy - Pourable Epoxy Grout

EcoPoxy 3000 is a two part component, high performance, pre filled epoxy liquid, suitable for use as a pourable or trowellable grouting material and in bonding new to old concrete. EcoPoxy® Fillers may be added to produce a trowellable high build mortar or a pourable, flowable grout.

Polyurethane

EcoDur - Waterborne Two Component Polyurethane Coating

EcoDur WB45 is a high performance two component waterborne polyurethane coating designed for application to concrete floors. EcoDur WB45 is available in clear and white with a range of colours available using the IC-Tint WB colourant system.

Sealers - Film Forming

EcoCryl - Waterborne Acrylic Sealer

EcoCryl WB S is a water based, 100% acrylic, self crosslinking, nano-polymer coating designed to be applied to horizontal concrete and masonary surfaces.

Sealers - Penetrating

PenSeal - Waterborne, Water and Oil Repellent Penetrating Sealer

PenSeal Ultra WB is a ready to use waterborne mixture of silane, siloxane and synthetic resins. It is used in diluted form to impart both water repellency and oil repellency to inorganic substrates such as mineral construction materials. In this respect, it differs from conventional (mono-functional) water-repellents. The pores of the substrate remain open, the water vapor diffusion is hardly affected, if at all. Oil, grease, paint, etc. are easier to remove from surfaces that have been treated with PenSeal Ultra WB.

Laboratory

Illawarra Coatings - Konig/Persoz Hardness Tester

The Konig/Persoz Hardness Tester measures the surface hardness of coatings. One of the advantages of using this type of equipment is that we can measure the increase in surface hardness with time thereby determining when our coating have reached full cure. Modifying the resin to hardener ratio in the formulation allows the cure time to be optimised for the specific coating application.

Illawarra Coatings - Impact Tester

Hard coatings are desirable, but they can also be too brittle for real life applications. Using our impact tester we can formulate our coatings to resist damage due to the impact of falling objects such as tools on maintenance shops or packaged goods in warehouses.