Imperial Machine Company (IMC) products

Bar & Refrigeration Systems

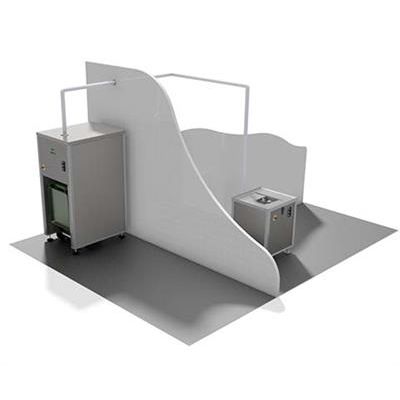

IMC - Mobile Hand Wash Station

IMC’s mobile hand wash station provides the perfect solution for outdoor catering, events and exhibitions where mains water is unavailable.

IMCool - Bottle Coolers

Stylish yet cost effective, IMCool bottle coolers keep bottles at the perfect serving temperature.

Bartender Range - Self Contained Workstations

Central to the successful use of Bartender is the IMC concept of creating compact self contained workstations. Each area then has everything required by individual bar staff, so they are instantly more efficient and productive. IMC’s Bartender offers a unique blend of style and functionality, to make any bar environment run smoothly and seamlessly. By day, evening or night, the Bartender is the ultimate bar-workstation, designed to make running a bar as easy and stress-free as possible, increasing sales as a result.

Vegetable Preparation

IMC - Potato Chipper

The PC2 Chipper is one of the fastest Potato Chippers available, producing 25kg of chips per minute, with minimum waste. Interchangeable knife blocks offer a choice of four chip sizes. The large hopper makes loading easy, yet the PC2 Chipper is compact enough for drainer, worktop or stand-mounting in any size kitchen.

IMC - Chipper

Despite its compact dimensions, IMC’s CS-C1 Chipper has a market leading capacity and is able to process up to 25kg of potatoes in just one minute. It can be mounted on a drainer, worktop or stand and is manufactured from heavy gauge stainless steel to provide years of reliable service and superior performance whilst being simple to wipe down and clean. Designed and engineered to bear the weight of a bucket of chips suspended from the chute. All welds are deep penetration, using the latest technology, for added strength and longevity. The patented screw-down, quick-release knife block assembly ensures blades remain rigidly in place to provide perfect chips with minimal wastage. Available in widths of 12mm, 14mm and 17mm, it can be removed quickly and easily for cleaning or replacement.

Waste Management

IMC - Auto Feed Waste Station

The Waste Station AF builds on the compact inlet station, and allows more than the single bucket feed of the WasteStation and WasteStation CR. Food is emptied into the collection chamber and auger feed into the maceration chamber. The macerated waste is then automatically fed into the remote dewatering system which reduces the volume by up to 80% and mass by up to 60%. The bulk loading and remote dewating feature of the Autofeed ensures maximum efficiency in busy kitchens.

IMC - Food Waste Disposers

Compact and space saving, IMC Food Waste Disposers offer excellent throughput and performance at low operating cost with a high degree of operator safety. IMC food waste disposers are built to ensure a long operating life, with each unit being constructed from hygienic stainless steel to withstand continuous use in the most demanding of applications. IMC food waste disposers are compact and efficient, combining safety and ease of use with performance, functionality and reliability. In addition, our wide range of products and options enable each unit to be specified to meet your exact requirements. Features include operator safety interlocks, automatic water controls, low-load cut-outs for energy and water efficiency, as well as reversible motors that extend operating life still further.

IMC - Food Waste Station

Food waste comprises of up to 80% liquid and can be extremely costly to dispose of. WasteStation CR combines an inlet station, which can be sited in the kitchen area, to grind the food waste into fine particles. These particles can be pumped up to 55m away were they are fed into a remote dewatering system. Through centrifugal action, the dewatering system forces out the excess liquid from the macerated waste. This “grey water” is fed directly to drain; the resulting solid fraction of the food waste is collected in 240 litre bins, ready for collection and onward processing.

IMC - Waste Station

Food waste is a major problem for any organisation that produces it. It’s notoriously difficult to process and dispose of safely and efficiently and is the most likely waste stream to contaminate other waste fractions. Food waste typically represents around 40% of total commercial catering waste. Of this 40%, approximately 77% is liquid. WasteStation grinds the food waste into fine particles, these particles feed directly into the built-in dewatering system. Through centrifugal action, the WasteStation forces out the excess liquid from the macerated waste. This “grey water” is fed directly to drain, the resulting solid fraction of the food waste is collected in small, easily managed, lidded bins, ready for onward processing.