In-Place Machining Company services

Concrete Sawing Services

Every concrete cutting job is unique. That’s why our engineering team develops a coordinated, visually-delineated plan to be followed on the job site to maximize efficiency while minimizing the time needed to complete your project. Concrete cutting typically employs the “pull” method of diamond wire saw cutting, where the diamond wire is threaded through a hole drilled at the top and bottom of the structure and guided through it via a series of pulleys. The process itself eliminates vibrations, does not weaken surrounding structures, produces no dust or flying debris and yields a smooth exposed surface without overcut corners to minimize re-work in new pours.

Metal/Undersea Cutting Services

On-Site Laser Alignment & Measurement Services

Precision Laser and Optical Alignment & Measurement, Plus Laser Tracker Instrumentation; In-Place Machining Company provides a wide range of laser and optical alignment, measurement, and inspection services that complement our on-site machining. With conceivably the largest and most diverse assortment of laser/optical alignment and measurement instrumentation, IPM is able to guarantee precise location, orientation and size measurements before, during, and after our machining operations. All our laser alignment & measurement equipment and instrumentation is calibrated on a regular basis with our in-house calibration equipment including a set of NIST traceable standards.

Robotic Demolition Services

Remotely controlled demolition robots have become increasingly popular to protect operators from hazardous working environments. From the 1970s until a few years ago, there was just one manufacturer: Brokk. Today there are machines from Husqvarna, HD Engineering and more.

Crankshaft Repair and Machining Services

In-Place Machining Company has been serving our customer’s needs with complete voyage and non-voyage Crankshaft Repair services in-situ for over 35 years. Whether your engine is land based, or aboard a vessel, In-Place Machining Company will provide custom equipment and expert technicians to restore your crankshaft to working order. Our technicians travel to domestic and international ports of call, board the vessel with our equipment, and make repairs while the vessel is berthed, or en route to the next port of call. Our logistics department works directly with vessel owners and agents to coordinate loading and offloading of equipment.

Specialty Drilling and Cutting Services

Cutting Edge Services specializes in developing unique solutions for particularly unusual drilling and cutting projects, including intricate drilling to support diamond wire sawing, and to create mechanical penetrations in new or existing facilities. We invite you to view representative clients and projects.

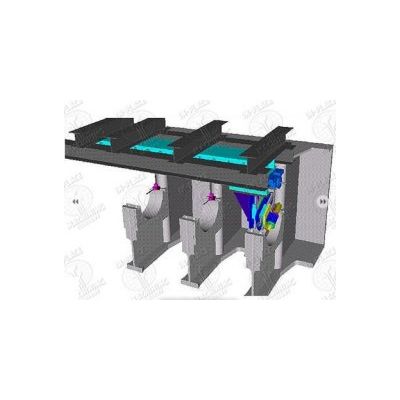

Engineering & Design Services

From the Largest Engineering Staff of Any On-site Field Machining Company. In-Place Machining Company’s engineers work with our customers to fully define the work scope and to identify various repair methods. We often model our work environment and machinery set-ups in 3-D in order to fully identify potential bottlenecks before they happen. In-Place Machining Company also uses state of the art design tools such as FEA to design and develop specialized machines that enable us to perform virtually any on-site field machining project with a high degree of expertise.

Metalstitch Cold Cast Iron Repair Services

In-Place Machining Company’s Metalstitch® Cold Cast Iron Repair process is the proven method for repairing cracked, damaged, and broken cast iron. We use advanced engineering methods such as 3D modeling and finite element analysis to determine the best repair geometry, and we select the right materials using our proprietary forged keys and precision machined studs. While Metalstitch® repair design and materials selection are important factors in making a successful repair, operator skill, experience and craftsmanship are equally important. Only In-Place Machining Company uses dedicated technicians trained in accordance with the Metalock International Association’s procedures, and only IPM technicians are fully certified by ABS, Lloyds, DNV and other certification agencies. Next time you need cast iron repair services, contact In-Place Machining Company to help get you back in service, In-place… Any Place in the World.

On-Site Certified Welding Services

In-Place Machining Company is also a leader in the mobile welding industry specializing in R-Stamp Certified On-Site Welding – another key aspect of our on-site machining services. In-Place Machining Company holds the National Board of Boiler and Pressure Vessel Inspectors R-Stamp #1781 for certified boiler and pressure vessel weld repairs. With emergency response and highly trained certified welders, our welding department can provide a quick certified repair, construct welding repair plans, and provide written documentation of the repair process. We will provide a safe and reliable mobile welding repair In-Place… Any Place in the World. IPM strictly conforms with the high standards that are set out by the National Board. We are committed to excellent craftsmanship and customer service, exceeding client expectations for quality, value, and safety.

On-Site Planetary Journal Machining, Grinding & Repair Services

The examples above represent only a few of the many types of shaft components that In-Place Machining Company is able to repair using our proprietary rotating planetary machining equipment. At IPM we pride ourselves on providing the highest quality, most responsive, and uniquely innovative On-Site Machining Services in the industry. Whether you have a small repair or a multi-unit modernization project, In-Place Machining Company will work with you to minimize downtime and stretch your budget dollars. Next time a scored or damaged bearing journal threatens your production, contact In-Place Machining Company to help get you back on-line, In-Place… Any Place in the World.