- Home

- Companies

- Indiana Group

- Products

Indiana Group products

Steel Bridges

Indiana - Fabricates Plate Girder

Indiana fabricates plate girder by welding plates together to create the desired shape. We receive large plates of steel in the desired thickness, which are cut into the flanges and web of the desired length and shape as per clients specifications. In a plate girder bridge, the plate girders are typically I-beams made up from separate structural steel plates which are welded.

Indiana - Open Web Girders

Indiana possesses a team of highly qualified engineers for fabrication and erection of open web girder up to span length of 61.2 meters. Indiana fabricates open web girders in railways of span of 30.5, 45.7, 61.0 and 76.2 meters. The fabrication facility at Indiana is capable to carry out the complete inspection and trial assembly of bridges and the assembly has to be done on firm and leveled platform.

Gratings

Rectangular Gratings

Rectangular gratings as the name suggests are non-radial gratings which may or may not include cut-outs / openings.

Handrails

Chainrails Safety Gates

Chainrails: If it is required that certain section of Handrail should be removable as and when required, we shall supply a double run of chain between two shanks. The ends would be supplied with `S` type hooks for attaching either permanently or temporarily to eyes fixed into the wall or shanks.

Raceways and Trunking

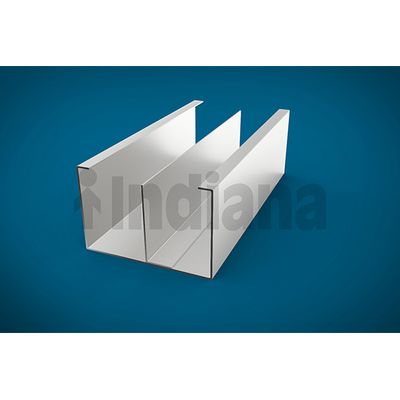

Trunking with Divider

Range of Width: 50mm to 900mm. Range of Span: 2.5m to 6m. Sheet Thickness: 1mm to 3mm. Finish Types: Hot Dip Galvanized, Painted, Powder Coated, Self Color and Electro polishing. Range of Height: 20mm to 150mm. Material: Mild Steel, Galvanized Iron, SS304, SS316, SS316L, Aluminum.

Finishing Process

Shot Blasting & Painting

Shot blasting process has become an integral part of steel structure and metal building industry. It removes all rush, mill scale and corrosion, thus eliminating moisture which is almost always entrapped beneath these corrosive products. It also provides ideal surface finish (SA2.5) for securing a bond between the steel surface and coat.

Hot Dip Galvanizing

Hot-dip galvanizing is the process of coating iron or steel with a zinc layer by passing the steel through a molten bath of zinc at a temperature of around 860°F (460°C). When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide, which further reacts with carbon dioxide to form zinc carbonate, a dull grey, fairly strong material that resists corrosion in many circumstances, protecting the steel from the corrosive elements. Galvanized steel is widely used in applications where rust resistance is needed, and can be identified by the crystallization pattern on the surface.