- Home

- Companies

- Indpro Engineers

- Products

Indpro Engineers products

Vibratory Feeder

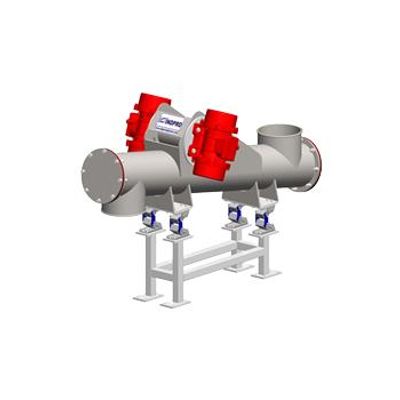

Indpro - Vibratory Tube Conveyor

A tube is driven by a contra-rotating pair of Vibratory motors to generate linear vibrations in a horizontal plane. This is very simple but great utility equipment and preferred over traditional screw conveyors for demanding conveying requirements. “INDPRO” Vibratory Tube Conveyor constructed with required sense of specific process needs.

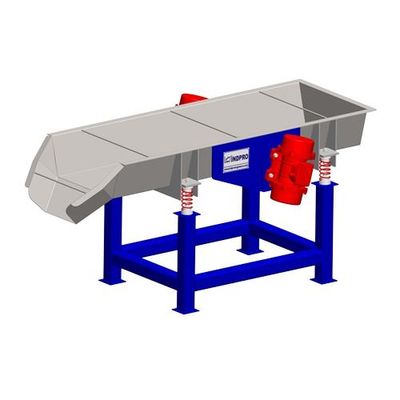

Indpro - Vibratory Pan Conveyor

A trough, is driven by a contra-rotating pair of Vibratory Motors for conveying dry bulk solids. The equipment can have suspended or foot mounting but usually installed below a Silo outlet and also for some specific conveying requirements. “INDPRO” Vibratory Pan Conveyor constructed with a detailed understanding of application and process requirements to aim a long lasting trouble free use at site.

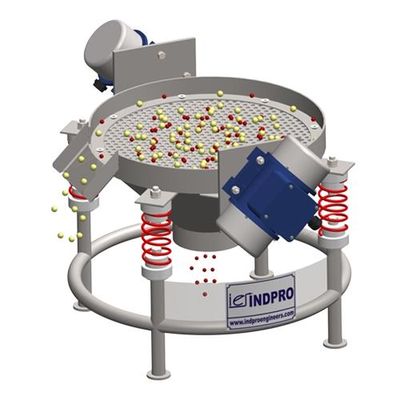

Vibratory Screener

Indpro - Vibratory Flow Thru Screener

Screening for oversized particles is very convenient while fines are collected in line. “INDPRO” Vibratory Flow Thru Screeners run on vibrators mounted out of the main screening deck to produce required gyratory vibration pattern. This is a tailor made, unique and compact design for a screening machine.

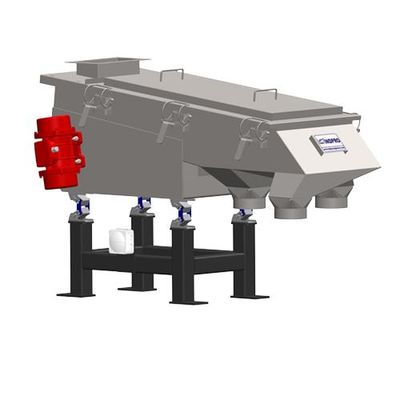

Indpro - Vibratory Rectangular Screener

The equipment is specifically built for plastic compounding / masterbatch units. The logic of working is to use rectilinear vibratory patterns to remove fines and double or triple uncut strands.

Others Products

Indpro - Bin Activator

A Bin Activator, most Commonly known as a Vibrating Bin Discharger is installed below a storage Silo to ensure on-demand, trouble-free discharge of stored Dry Bulk solids. “INDPRO” Bin Activator is the Ultimate Solution to overcome Discharge Problems associated various types of stored Bulk Solids

Indpro - Vibratory Spiral Conveyor

Though Design and Construction of “INDPRO” Vibratory Spiral Conveyor is extremely exhaustive and critical but the end result is a simple and user friendly machine for a complete ease of process’s operational requirements. Any semi skilled operator can handle it, once set. Vibratory Motors installed to drive “INDPRO” Vibratory Spiral Conveyor are always from best in industry, from internationally well known makers, to give a really long trouble free operational life. Meeting the layout’s demand Vibrator Motors can be installed at top or bottom of the spiral track assembly, Vibratory Conveying capacity remains same in either of the cases.

Indpro - Vibratory Spiral Elevator

Vibratory Spiral Elevator is a utility equipment for vertical conveying, against gravity, of Bulk Solids using mechanical vibration technology.

Indpro - Vibratory Bag Compaction Table

The use of FIBC or jumbo bags is now the most preferred among process industries. The challenge is to utilize the full volumetric capacity of this bag during filling. It is a must to have an automated system during filling to ensure air pocket release, thereby achieving total weight capacity.

Indpro - Vibrating Bin Aerators

This flow promotion device works on compressed air. It is installed on the cones of hoppers / bins / silos from inside and generates Aeration & Vibrations during ON time.

Indpro - Model FIBC - Unloading Station

Bulk solids, especially powdery material, tend to compact when they travel in bulk bags or jumbo bags for long distances. Discharging at the destination becomes challenging, and therefore a system is needed for emptying these bags for further processing. Out of many traditional methods, vibration technology-based mechanisms are the most perfect solution.