- Home

- Companies

- Industrial Physics

- Products

Industrial Physics products

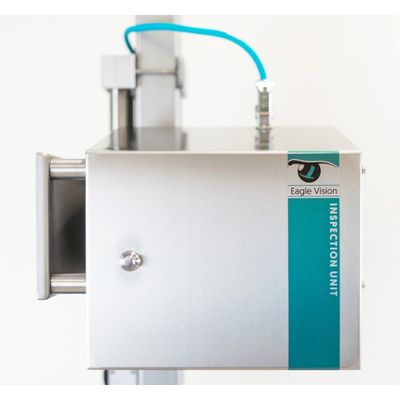

Eagle Vision

Eagle Vision - 360° Can Inspection Module

The 360° Can Inspection module is a highly accurate Mix-Up & Integrity Detection system for cans.

Eagle Vision - 360° Label Inspection Module

The 360° Label Inspection Module is a complete final inspection for labeled bottles, jars, cups, cans and various other types of packaging.

Eagle Vision - Dirty Tray Vision System

How to achieve huge cost reductions in starch moulding in only one step? The DTV Dirty Tray Vision System is the first and best innovative solution since 25 years to prevent bad imprints and dirty trays during starch moulding production.

Eagle Vision - Empty Can Inspection System

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can. Pollution and spots on the inside, as well as flange dents, flange width and ovality/roundness are being inspected. The Empty Can Inspection system is available for high speeds.

Eagle Vision - Metal Ends Inspection Module

The Metal Ends Inspection module inspects damages, roundness and compound on metal can ends. This includes scratches, dents, rust, contamination, compound misapplications and more.

Eagle Vision - Code Reading Modules

The Code Reading modules inspect ink-jet, laser and thermal-transfer codes on various packaging types, including infant formula cans, food cans, beverage cans, labels, cartons, film, foil and PET bottles. The inspection checks if codes are present, complete, readable and correct. Code Reading assures you compliant Best Before Dates and Lot Codes, detection of mixed-up packaging and registration of serialization anti-fake codes. We have special modules dedicated for reflective or round surfaces, like cans and bottles. We deliver standard solutions ideal for High Speed performance, up to 144.000/hour, as required in the beverage industry. Most of our solutions can run fully automated, fitting the Industry 4.0 movement. Operating in a hygienic high care, food or wet beverage environment? No problem, we have a proven and easy-to-use solution for you. With service levels up to 24/7 support and a global network of service partners, ongoing support is always by hand.

Eagle Vision - Scoop Inspection Module

The Scoop Inspection module inspects very accurately the scoop presence, broken scoops, double or multiple scoops and mixed-up/incorrect scoops by color. The Scoop Inspection module is also able to inspect white and transparent scoops.

Eagle Vision - In-line Seam Inspection System

The Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively. Lab measurements equipment is highly accurate, but based on sampling a selection of the entire production. Because of that defective seams can be detected too late and inconsistently. Or worse; by the customer. The In-line Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively. Various can sizes and can shapes are inspected without any product handling. The inspection is available for high line speeds.

Eagle Vision - Cap Inspection System

The Cap Inspection can inspect for correct Cap Positioning, Cap Mix-Up, and correct Cap Orientation. Leaking products is one of the most common risk issues. At first it frustrates the production process by leakage and pushed off loose (snap)caps . And worse, it has effect on the product integrity and customers health.