International Cooling Tower USA, Inc. services

Engineering & Design

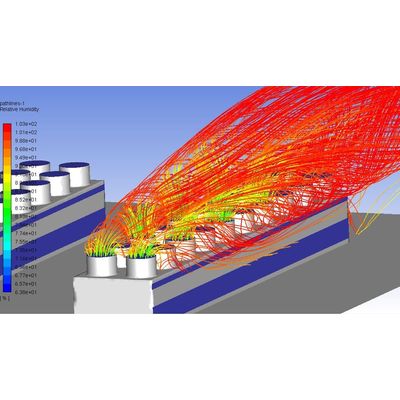

Engineering Studies Services

Our engineering team provides a wide range of services to our clients, from FEED study information and tower siting to Plume Studies using CFD modelling to Structural and Hydraulic computations as well as thermal modelling of the tower’s operation. Our clients benefit from our EPC level approach to engineering every project before design or construction begin, ensuring the tower will operate at maximum efficiency.

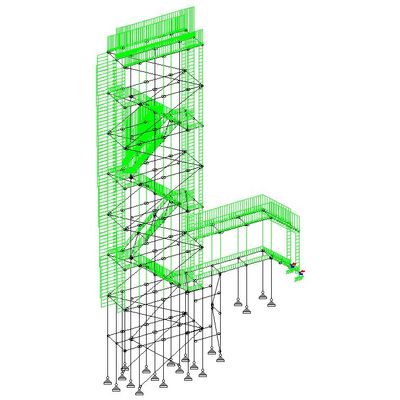

Design Build Services

Our new tower design utilizes state of the art structural, hydraulic, and thermal design models to optimize the tower offered. Optimizing tower design for constructability and future repairs are essential for many of our clients. Understanding the everchanging operating parameters regarding water usage, chemical usage and power consumption are all considerations when we design a cooling tower.

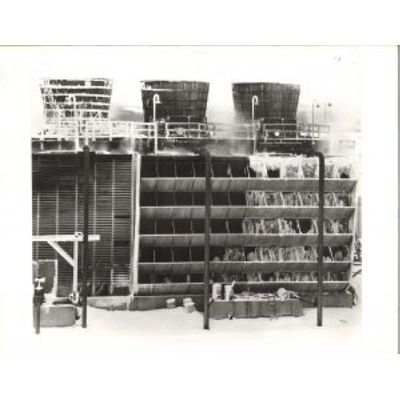

Aftermarket Replacement Services

Repair and replacement of cooling towers is one of our strengths. Having maintained many of our client’s towers from the day they were installed to the day the plant is decommissioned allows us to fully understand the life cycle of a cooling tower and its component replacement intervals. Our construction and engineering focus ensures we collaborate with our clients to make sure the latest technologies are considered when a tower is up for repair or replacement.

Maintenance Services

Field Services

ICT’s Field Services teams are recognized in the industry for their ability to complete projects safety. This is a core value and the basis for our best practices when creating innovative ways to protect our workers and optimize productivity. We are a direct hire company and employ all of our field crews to ensure we have the best people and the most highly trained workforce. Our innovative methods include safe work platforms installed on each working surface of a tower, mobile assembly towers for larger installations and module assembly to limit down time for customers. We have over seven different methods to assemble or reconstruct your cooling towers. We leave no option unexamined. ICT chooses the best and safest construction method for your project.

Inspections Services

ICT conducts a range of inspections depending on a client’s individual cooling tower requirements. These include; age, condition, severity of service and type of material. Once the requirements are determined, the level of inspection can be planned. From a simple walk-down to a Level 3, remove fill, our trained inspectors work together with our engineers to provide a comprehensive report. Photos of deficiencies, bent line drawings are all reviewed by our Engineers who are able to provide material testing for both wood and FRP. Any type of inspection can be custom tailored to help plan future capital expenditures or confirm a tower is fit for service.

Winter Operations Services

ICT is the recognized subject matter expert (SME) in operating cooling towers in freezing conditions. Whether its optimizing tower operation, or upgrading tower systems for better winter operation, our engineers have seen it all. We have created PLC logic controller programs to have automated tower operation in almost any weather condition; developed inlet doors and controllable louvers for trouble free winter operation and partitions and cell isolation procedures for reduced flow applications. We can even operate without a headload – We have experienced it all.

Construction Services

Turn Around Times Services

Our team can complete almost any project during a turn around- from complete replacement to inspections / preventive maintenance and minor repairs. Our onsite teams really do it all. Our construction group is the most experienced group in all of North America. Our teams have the ability to assemble a cooling tower in a number of different ways depending on the project requirements. Our team includes Construction Managers, Superintendents, Foremen, Safety professionals, Quality control inspectors and specialized trades that are the key to our success.

Construction Methods Services

Our construction group is the most experienced group in all of North America. Our teams have the ability to assemble a cooling tower in a number of different ways depending on the project requirements. Our team includes Construction Managers, Superintendents, Foremen, Safety professionals, Quality control inspectors and specialized trades that are the key to our success.

Safety Services

We are recognized as the industry leader in safe assembly and construction of cooling towers and our safety record shows our long-term commitment to making sure all of our employees return home to their families every day. Our extensive training programs which are specially developed for the rigors of cooling tower construction are the foundation of the safe work methodology that we hold as a core value. We have developed several unique methods to assemble cooling towers depending on the requirements of the project we can select the optimal assembly method to provide maximum safety benefits.

Emergency Response Services

We are the first call many of our clients make after any emergency whether that is tornado, fire, flood, hurricane or catastrophic failure we rise to all occasions. Our vast experience, procurement relationships, inventory and skilled workforce all combine to be able to respond to any client emergency.