- Home

- Companies

- InterSpec LLC

- Products

InterSpec LLC products

Training Services

All inspection seminars offered through InterSpec are oriented toward engineering evaluation, inspection procedures, repair techniques, problem-solving, and individual qualification requirements in non-destructive examination (NDE) and welding. Certificates are received upon completion of each seminar. Course seminars range from 1 to 5 days. Classes with a minimum of six (6) students, can be specifically designed and taught at the location of your choice.

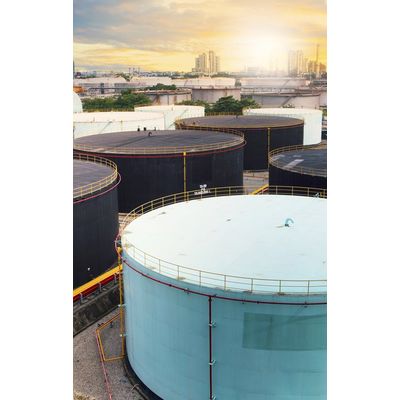

Tank Inspection Services

API-653 Out-of-Service Inspection

American Petroleum Institute (API) Standard 653 is the Industry Standard most commonly used for tank inspection repair, alteration, and reconstruction. Out-of-service tank inspections, sometimes described as internal inspections, are formal complete inspections that are conducted by authorized inspectors on all accessible internal and external areas of tank surfaces, piping, and appurtenances. This type of inspection requires tanks to be out of service so that a thorough internal evaluation can be conducted. Tanks are evaluated for integrity and suitability for service. Tanks are inspected for leaks, corrosion, and any other possible or potential leakage of fluids or product that might cause environmental damage.

API-653 In-Service Inspection

American Petroleum Institute (API) Standard 653 is the Industry Standard most commonly used for tank inspection repair, alteration, and reconstruction. The in-service inspection, sometimes described as external inspection, is conducted by an authorized inspector and includes a visual inspection of the tanks exterior surface. This inspection is usually conducted while the tank is in operation or when the interior is not assessable or available for inspection. During the in-service inspection, InterSpec inspects the tank systems for evidence of leaks, shell distortion, signs of settlement, corrosion, and the condition of coatings, insulation, and appurtenances.

Fiberglass Tank Inspection Services

FRP (Fiberglass Reinforced Plastic) Tank inspections are conducted in accordance with the Fiberglass Tank & Pipe Institute’s Recommended Practice FTPI-1. InterSpec’s certified inspectors are qualified to perform FRP inspections. A Certified Tank and Vessel External Inspection is required every 5 years for tanks and vessels in Hazardous Substance service and every 10 years for tanks and vessels with a greater than 10,000 gallons capacity and in other service. A Certified Tank and Vessel Integrity Inspection is required every 20 years for tanks and vessels in Hazardous Substance service as well as those having a greater than 10,000 gallons capacity and in other service.

Piping Inspection Services

API-570 Piping Inspection, API-580 Risk-Based Piping Inspection, API-1110 Pressure Testing, 49 CFR 195 Compliance, Hydrostatic Testing Witness & Compliance (including California’s Fire Marshall OSFM requirements),

Pressure Vessels Inspection Services

API 510 Pressure Vessel Inspections, OSHA’s Process Safety Management (PSM) Mechanical Integrity, Rating or Re-Rating Pressure Vessels, LRUT (Guided Wave) Evaluations, CUZ Evaluations.

Environmental Services

Process Safety Management (PSM) Services

InterSpec provides third-party reviews for the design and cost-effective development of repair specifications, test procedures, compliance reviews, and performance of PSM audits IAW 29 CFR 1910.

SPCC Plans Services

InterSpec engineers have extensive experience with the US EPA’s oil pollution prevention program. The newly effective requirements for development and upgrading spill prevention, control and countermeasure plans (SPCC) have been a major focus of InterSpec’s daily routine. InterSpec develops and implements SPCC Plans in accordance with the requirements of EPA’s Oil Pollution Prevention regulations and Guidance

Facility Response Plans (FRP) Services

InterSpec’s Facility Response Plans (FRP) simplify our customers’ requirement to develop and implement their written protocol in response to a spill. Our experienced Professional Engineers (P.E.) are well versed in development, giving our customers peace of mind and a thorough plan.

Oil Discharge Contingency Plan (ODCP) Services

State requlations, such as Virginia’s, require an Oil Discharge Contingency Plan (ODCP). InterSpec’s Plan Development Department specializes in creating a comprehensive, P.E. certified plan to ensure compliance with state regulations.