ITS - Shredding & Grinding Solutions products

ITS - Granulator

The ITS granulators are designed to be integrated in complete recycling plants. The special staggered blade rotor design make them the perfect choice when processing textile, pre-shredded tyres, RDF and other materials. A variety of rotor lengths and diameters and the possibility of installing various motor sizes will satisfy most grinding requirements.

ITS - Model SRF Series - Secondary Shredder System

The SRF series of secondary shredders have been designed specifically for the size reduction of industrial, commercial and municipal solid waste for the production of Solid Recovered Fuel (SRF) and in other recycling application. These shredders are available with rotors diameter ranging from Ø670mm to Ø900mm and rotor lengths ranging from 1700mm to 2300mm with different rotor cutting configurations designed for specific materials. These machines designed for low power consumption are controlled by a PLC connected to an inverter which allows to modify the rotor speed based on the shredding requirements while maintaining the same working torque. This series of shredders are suitable to process large volumes of waste such as paper, cardboard, plastics, rubber, textiles, etc.. As well as production of Solid Recovered Fuel for co-generating plants and for the cement industry.

ITS - Grinder Blades for Plastic Processing

We are specialized in the production of grinder blades for processing plastics and other type of materials. The use of special high quality steels guarantees durability and low running costs. We can design and manufacture any type of blades for specific applications. We also produce single pieces following our client`s drawings and specifications. We can service grinder and re-sharpen blades.

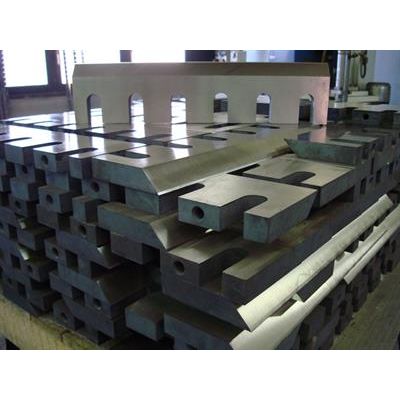

ITS - Shredder Blades

Our blades are engineered to guarantee a superior performance both in terms of resistance and wear in various shredding applications. The use of high quality steels and our strict procedure during the heat treatment process allow several re-sharpenings reducing maintenance costs. We manufacture blades for single shaft, twin and four shaft shredders. We can design and manufacture any type of blades for specific applications. We also produce single pieces following our client`s drawings and specifications. We can service shredders and re-sharpen blades.

ITS - Model H-Series - Shaft Low Speed Shredders

ITS - Model HD-Series - Low Speed High Torque Shredder

These series of heavy duty two shaft low speed, high torque shredders guarantee the highest degree of reliability and performance when processing high volumes and very demanding material. Each shaft is independently driven by a dedicated hydraulic motor which allows maximum power to each shaft. Each drive can be set to vary the speeds in the cutting chamber optimizing performance under heavy loads. A dedicated PLC user-friendly touch-screen controls the setting and working of the shredder.

Single Shaft Shredders

ITS - Model ZWS - Single Shaft Shredder

The single shaft shredder ZWS are equipped with a large feeding hopper and an hydraulic ram designed to push the material between the rotor and the fixed blade. The hydraulic ram is designed to exert pressure on the material depending on the absorption of the rotor. These shredders are designed for the wood industry to grind small quantities of off-cuts in a joinery or to create sawdust from all kinds of waste wood to be used as fuel directly or further processed in a briquetting press to create heating pellets. This series can be also used in the plastic industry to process lump cakes and heavy plastic components. They are designed to withstand the demands of continuous operation.

ITS - Model ZSS/ZIS - Single Shaft Shredder

These single shaft shredders are designed with a small powerful internal hydraulic ram which eliminates the risk of blocking and wearing out of internal guide rails. These machines can be supplied with rotor cooling or can be equipped with a wear package for the processing of highly abrasive, filled materials.

ITS - Model ZXS - Single Shaft Shredder - Heavy Duty Series

The single shaft shredders ZXS are designed with a powerful two speed swing ram to eliminate the risk of blocking and wearing out of internal guide rails. The low speed of 45 rpm guarantees a high torque and smooth operations. The machine is very versatile and can be used for shredding all kinds of materials: plastics, wood, paper, cardboard, e-waste, post consumer waste, rubber, etc. in various shapes and sizes. Typical input materials are: refrigerators, large purgings, tires, pallets, bales, drums and barrels, pipes, film, RDF etc... The final output size depends on the screen size. For the recycling of pre-shredded truck and tractor tires the ZXS series is configured with special blades and wear protections.

ITS - Model ZRS - Single Shaft Shredder for Large Thick Pipes

The ZRS shredder has been designed to process thick and large diameter pipes (up to Ø 1200mm) without pre-cutting. It is suitable to cut bundles of smaller pipes and profiles in HDPE, PP and PVC. The shredders are available with rotors diameter ranging from 800 to 1500mm depending on pipe diameter. The standard hopper accepts pipe lengths of up to 6 m. The combination of advanced controls, low rotor speed and smooth hydraulics create a reliable and easy to use system. These machines can also be used for recycling of other plastic materials such as large lumps, wheelie bins and pallets .