ITW Performance Polymers products

Chockfast

ITW-Polymers - Model Chockfast Gray -PR-610FR - Inert Filled Casting Compound

CHOCKFAST Gray (PR-610FR) is a specially formulated 100% solids, two component, inert filled compound developed for use in chocking non-precisely aligned equipment or in setting anchor bolts in concrete. The compound is designed to withstand severe marine and industrial environments involving a high degree of both physical and thermal shock. The compound is non-shrinking, non-burning and has a very high impact and compressive strength. Years of successful experience have shown the use of PR-610FR to be a far superior yet less expensive method of establishing and retaining equipment alignment under extreme conditions. When poured as a continuous chock under deck equipment, CHOCKFAST Gray provides a corrosion proof moisture seal. PR-610FR is approved or accepted for marine use by A.B.S., Coast Guard, Lloyd’s Register and other regulatory agencies.

Densit

ITW-Polymers - Model Densiphalt - Semi-Flexible and Joint-Free Topping System

Densiphalt is a semi-flexible and joint-free topping system, well suited for use in heavily trafficked areas where flexibility, durability and wear resistance are high priorities. Densiphalt is a composite paving material that combines the flexible properties of asphalt with the static bearing capacity and durability of concrete.

ITW-Polymers - Model Densit Coat Q5 - Shrinkage Compensated High Performance Spraying Mortar

Shrinkage compensated high performance spraying mortar with extreme capability to bind to old as well as new concrete surfaces. Suitable as top layer coating for Densit Coat Q25.

Devcon

ITW-Polymers - Model Devcon - 1 Minute Epoxy Gel

Ultra-fast-curing, thixotropic adhesive gel adhesive for filling gaps, cracks and holes in metals, wood, concrete and glass.

ITW-Polymers - Model Devcon - 2 Ton Epoxy Adhesive

Extremely strong, water-resistant epoxy adhesive that forms a powerful bond with ferrous and non-ferrous metals, ceramics wood, concrete, or glass in any combination.

ITW-Polymers - Model Devcon - 5 Minute Epoxy Adhesive

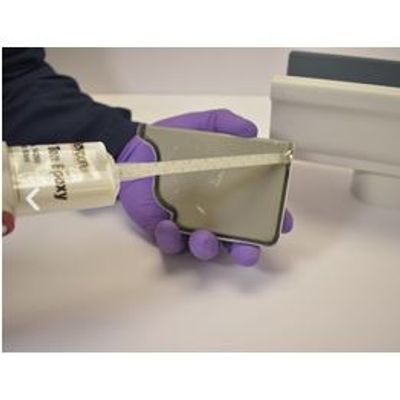

Looking for a fast and durable solution to protect your pipe infrastructure? Look no further than Devcon 5 Minute Epoxy – the ideal epoxy hardener for all your repair and maintenance needs. Our innovative epoxy mixture is a rapid-curing, general-purpose adhesive that easily dispenses and mixes in seconds, providing fast and effective gap filling solutions for a wide range of applications. The five minute epoxy resin dries in just 15 minutes and reaches functional strength in one hour, making it an ideal solution for those in need of a quick and reliable fix. Our polypropylene epoxy and 5 minute 2 part epoxy are both tough and resilient, ensuring that your pipe infrastructure is safe from damage and wear. Don’t wait any longer to protect your pipe infrastructure – try our Devcon® 5 Minute® Epoxy today and experience its superior bonding strength and flexibility for yourself.

Epocast

ITW-Polymers - Model EPOCAST 36 - Two-Component Pourable Chocking Compound

EPOCAST 36 is a two-component pourable chocking compound with excellent physical characteristics replacing the conventional method of steel chocks when used for mounting main and auxiliary engines, gear boxes, steering gears, thrust bearings, stern tubes, etc. EPOCAST 36 chocks are not only economical to fit but offer additional benefits such as their ability to fill any reasonable irregularity in the chocking interface and to reduce noise and vibration.

ITW-Polymers - Model EPOCAST 36-P - Trowelable Two Component Epoxy Paste

EPOCAST 36-P is a trowelable two-component epoxy paste which was specifically developed for installation of LNG/LPG tanks, chemical tanks and containment systems. EPOCAST 36-P is a further development of the worldwide proven chocking and grouting system EPOCAST 36 and is everywhere in application where it is not practical to use a freely floating resin. EPOCAST 36-P can be heavily loaded and has good adhesive properties even at extremely low temparatures.

ITW-Polymers - Model EPOCAST F - Two Component Resin System

EPOCAST F is a two-component resin system enriched with high-grade fillers. It is designed for use wherever there is a need to join different components and ensure a permanently flexible seal. Low heat production during the curing process even under high chock conditions, and smooth, pore-free surfaces are the outstanding features of this product.