J P Specialties, Inc. products

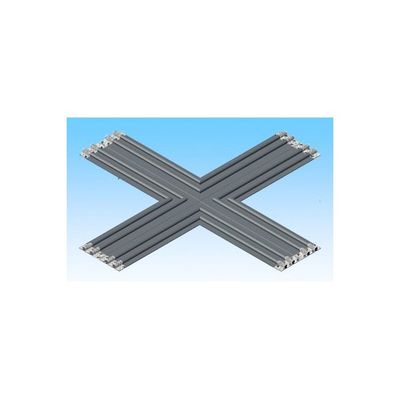

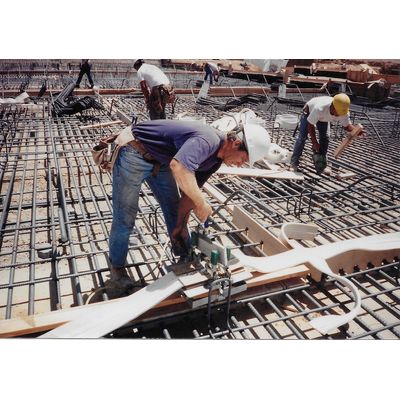

Waterstop Fittings

Why the Engineer Should Specify Shop Made Fittings. Shop Made Fittings are recognized and specified worldwide by major engineering firms. The U.S. Army Corps of Engineers also specified Shop Made Fittings in the July 1995 revision of CEGS Section 03250. Shop Made Fittings are specified because they work. Edge-welding waterstop severely compromises the integrity of any project. Even the limited movement of concrete during the coefficient of expansion and contraction can be too much for edge welded waterstop. The edge welded waterstop lacks the proper tensile strength and does not maintain the characteristics of the parent material (bulb or rib continuity).

Earth Shield - Model VEN 1000, 500 and 250 - Trowel Grade Epoxy Gels

Earth Shield® VEN 1000, 500 and 250 are trowel grade epoxy gels designed to adhere Earth Shield® Retrofit Waterstop (part no. 320L, 336L, 325T, 450T, et al) to existing concrete surfaces.

Waterstop

Earth Shield - Model TPV - Thermoplastic Vulcanizate Waterstop

Earth Shield® Thermoplastic Vulcanizate Waterstop (TPV) (aka TPE-R) is used as a fluid-tight diaphragm, embedded in concrete, across and along the joint, for primary and secondary containment structures. Earth Shield® Chemical Resistant Waterstops are resistant to a wide range of oils, solvents, and aggressive chemicals. Alcohol, ketones, glycols, esters, and aqueous solutions of acids, salts, and bases have little effect on Earth Shield® Thermoplastic Vulcanizate Waterstop.

Earth Shield - Flexible Polyvinyl Chloride (PVC) Waterstop

Earth Shield® Polyvinyl Chloride (PVC) Waterstop is used as a fluid-tight diaphragm, embedded in concrete, across and along the joint, for environmental engineered concrete structures. Earth Shield® Flexible PVC Waterstops are resistant to a wide range of water and wastewater treatment chemicals and are certified to meet or exceed the performance requirements of CRD C572-74.

Earth Shield - Stainless Steel Waterstop

Earth Shield Stainless Steel Waterstop can stop even the most corrosive fluids in their tracks, even at severely elevated temperatures. A variety of metals, grades, and gauges are available. Earth Shield utilizes 20 gauge 316 low carbon as our standard alloy, which offers broad spectrum corrosion resistance to most aggressive media, and is virtually untouched by the deleterious effects of ozone, making it an ideal choice for ozone contactor structures used in modern water treatment plants.

Earth Shield - Carbon Steel Waterstop

Many projects, especially those designed by Black & Veatch Engineers, require the use of Carbon Steel Waterstop. J P Specialties manufactures Carbon Steel Waterstop in a variety of shapes, gauges, and grades.

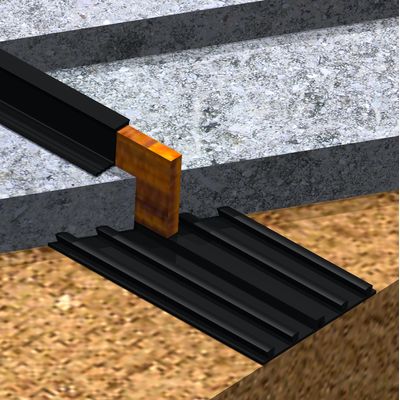

Earth Shield - Column and Pipe Fitting Waterstop

Earth Shield® has solved a long-standing problem for engineered concrete structures with circular protrusions, such as columns, pipes, piers, and pilasters. The problem: how to permanently seal the concrete joint when cast-in-place concrete forms against an existing circular member. The solution: Earth Shield® Column & Pipe Fitting (part no. JP320LC1.XX* [*XX is the diameter in inches]) manufactured with a flexible, chemical-resistant polymer and stainless steel anchoring hardware. A single laborer on the job site can quickly install the column fitting and its associated hardware. Just apply an epoxy gel bed to the existing surface; place the polymer ring into the epoxy gel bed; heat weld the single opening on the polymer ring using a waterstop splicing iron; and finally, complete the system with the stainless steel closure ring.

Earth Shield - Model Type NB190 - Modified Chloroprene Rubber (MCR) Hydrophilic Strip Applied Waterstop

Type NB190® is a modern, hydrophilic chloroprene rubber waterstop with unmatched durability and water sealing capabilities. Manufactured NON-BENTONITE, modified chloroprene rubber, Type NB190® more than doubles its original size (400% in 36 days) when exposed to water. This expansion creates an effective compression seal within joints of limited to no movement. Type NB190® can expand and reexpand unlimited times with virtually no loss of physical properties. Additionally, Type NB190® has excellent resistance to many chemicals, is heat-resistant, and is safe for drinking water (NSF 61 certified).

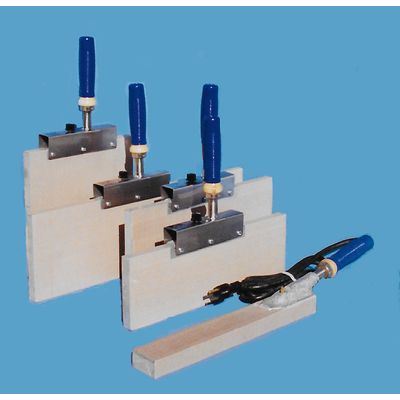

Waterstop Tools

JPS - Waterstop Splicing Irons

JPS Standard Irons are specifically designed for welding waterstops and other thermoplastic extruded profiles (expansion joints, seals, etc.). The temperature control can be adjusted from 250°F to 500°F to accommodate various ambient conditions and different polymers. All JPS Standard Irons are constructed with the highest quality components.

JPS - Analog Thermometer

Analog thermometer add-on for JPS standard waterstop splicing irons. Displays the correct temperature for welding thermoplastic waterstops and expansion joints. Dual-Gauge (Celsius and Fahrenheit) Temperature range: 150°F to 750°F. 12150 part number fits 12414, 12415, 12614, 12615, 12620, 12621, and 12919.