- Home

- Companies

- Jaeger Aeration

- Products

Jaeger Aeration products

JetFlex - Diffuser Assemblies and Replacement Membranes

The JetFlex diffuser assemblies and replacement membranes are perhaps the world’s most advanced fine-bubble diffuser membranes for aerator wastewater systems and water treatment. The JetFlex diffuser tube and diffuser disc combine the highest oxygen-transfer efficiency and low energy usage. They’re engineered and manufactured by Gummi-Jaeger AERATION, which in 1983 invented the world’s first EPDM fine-bubble diffuser membrane. In some case studies, Gummi-Jaeger AERATION tube diffuser and disc diffuser (disk diffuser) products provided a useful life of up to 10 years or more – providing service three times times longer than their projected product life.

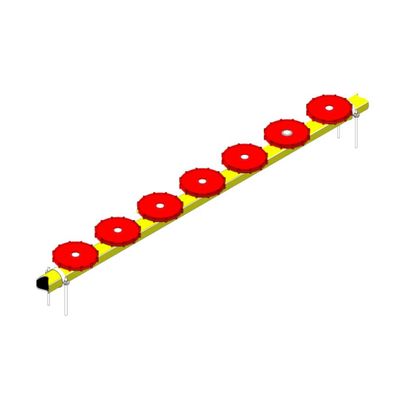

OxyStrip Diffusers

Industry max. 8:1 Diffuser Turn Down - 2.5 SCFM to 22.0 SCFM range per 2m OxyStrip™, 4.0 Nm3/h to 36.0 Nm3/h range per 2m OxyStrip™. 20% to 40% more efficient - reduction of utility cost. Membrane materials & expected life - EPDM, Silicone, & Polyurethane, > 10 years. One 2m long OxyStrip™ is equal to 9 times 9” disc. Installation: Retrievable or fixed grid, Up to 90% Reduction of pipe & couplings

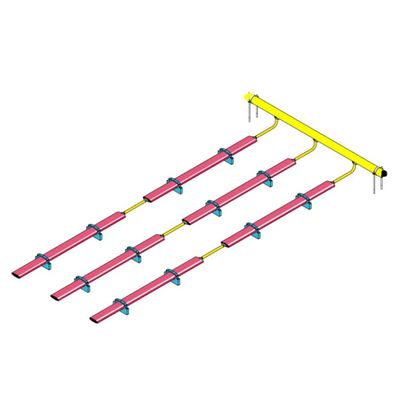

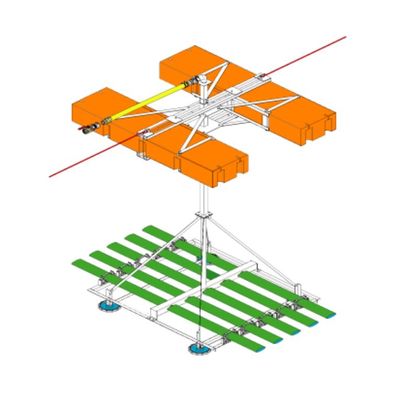

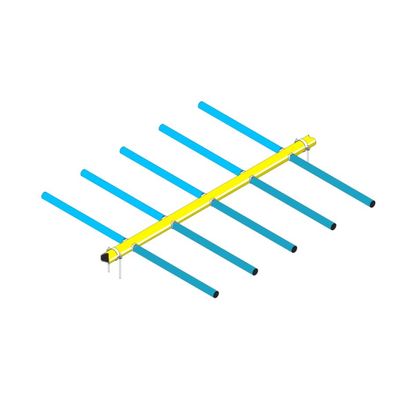

OxyLift Design

Retrievable rack: Multi-level system redundancy, One OxyLift diffuser rack = 162 9” disc diffusers. Diffuser rack retrieval in 2 minutes: Rack transfer system for diffuser maintenance, Movable hoist and transfer system. No retrievability limitation by basin geometry: Rectangular, round, toroidal, and square, Bridge or wall mounted. OxyProcess compatible design

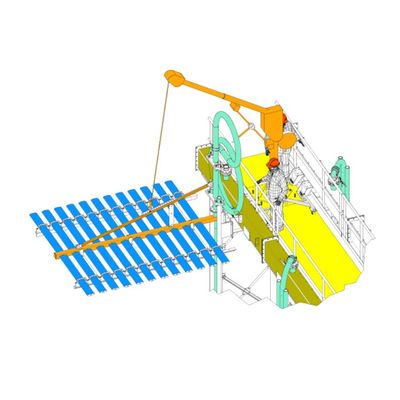

Dual-Air-Control Design

One set of Dual-Air-Control – OxyStrip diffusers equals eighteen 9” disc diffusers. Up to 40 % Power Savings / Energy Conservation. Airflow range: 2.5 SCFM to 44.0 SCFM, 4.0 Nm3/h to 72.0 Nm3/h. 16:1 system turn down: Organic loading optimization driven, OxyProcess compatible design

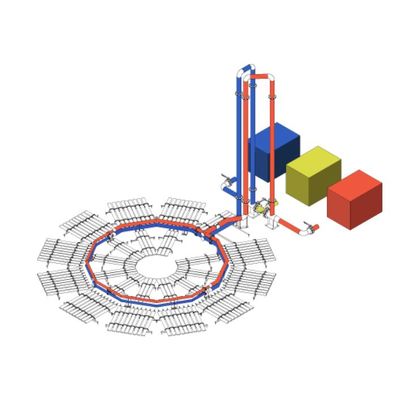

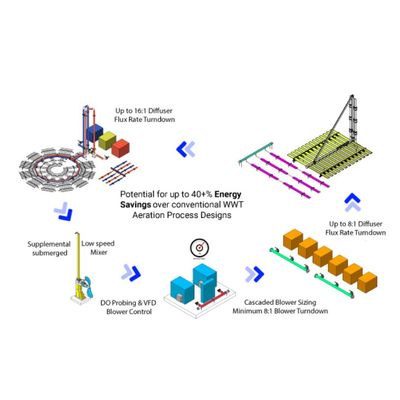

OxyProcess Design

Predictable effluent, TN, TP: BNR for low NPDES permits, OxyLift, OxyStrip, Dual-Air-Control products. 20% - 40% Energy Reduction: Separate aeration from mixing energy, Infinite recycle provides increased MLSSR. Load Oriented Oxygen Demand Supply: DO (Dissolved Oxygen) Meter Control, ORP (Oxidation Reduction Potential) Meter Control. Control Scheme & SCADA Monitoring: Plant wide SCADA systems, LAN for Ethernet communication. Redundancy allows for reduced capital cost: Anoxic and Anaerobic basins not required

OxyPod

Lagoon Aeration: Oxidation for BOD removal, NH3 – Nitrification, Mixing. Deployment Method: Floating Pontoons for variable water levels, Self-weighted drop in & retrievable rack system. Mixing & Aeration: Area of influence up to 50’ [15m], Depth installed 5’ to 30’ [1.6m to 9m]. Mechanical plants: Replacement of aeration equipment, Supplemental aeration system

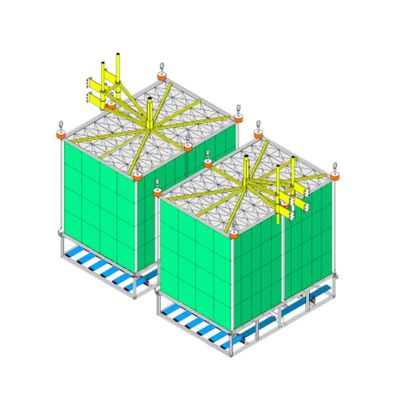

BioCube Process

Biofilm attached growth systems for BOD and nitrogen removal from wastewater. Fixed film media units design options: Single pass, Return sludge IFAS systems. Retrievable, drop-in FBBR modules. Increasing the BOD removal performance / increase biomass (suspended & fixed) by up to 60% by tank volume

OxyDisc Diffusers

Retrofit to existing equipment. Fixed grid design only. Membrane materials: EPDM, or Silicone. Continual & automatic condensation purge system. Factory pre-assembled, tested, & certified diffuser modules & grid sections available.

OxyTube Diffusers

High efficiency fine Bubble membrane tube diffuser: 10% Higher SOTE over entire design airflow range, 10% Power Savings / Energy Conservation over conventional 9” disc. 2x1m long OxyTube™ diffusers pair = 5 x 9” disc diffusers. Reduce lateral air distribution piping and number of diffusers components needed by Factor 3x vs. 9” disc diffusers systems. Fixed grid & retrievable fine bubble membrane diffuser system