Jansens Aircraft Systems Controls Inc. (JASC) products

Power Generation - Fuel Systems Valves

JASC - Thermal Relief Valve

JASC’s Thermal Relief Valve is a passive valve designed to relieve fuel pressure build-up due to fuel heating. (Thermal expansion yet the Thermal Relief Valve remains closed during normal liquid fuel system operation). fuel system operation).

Power Generation- Purge Air Valves

JASC - Purge Air Check Valve

JASC has manufactured and shipped over 12,000 Purge Air Check Valves for use on heavy-duty gas turbine engines used in power generation. The JASC Purge Air Check Valve is designed for continuous through-air operation with air temperature in excess of 400° F and operating pressure up to 1200 PSIG. JASC’s Purge Air Check Valve is designed to operate on water, Stoddard solvent, naphtha, jet fuel, diesel fuel, synthetic oil and hydraulic oil.

Power Generation- Fuel and Purge Air Valve Systems

JASC - Water Cooled Three-Way Purge Valve

The JASC Water Cooled Three-Way Purge Valve was developed in response to liquid fuel coking that will occur when valves are on an engine and exposed to heat for an extended period of time while the turbine is operating on gas fuel.

JASC - Three-Way Purge Valve

JASC developed the Three-Way Purge Valve to replace problematic liquid fuel and purge air check valves on dual fuel industrial gas turbine engines.

JASC - Water Cooled Combining Valve

JASC’s Water Cooled Combining Valve improves dual fuel turbine engine performance and reliability. This valve design is uniquely suited for use on base loaded turbines or turbines which have long operational cycles. With recommended maintenance intervals that are a minimum 24,000 hours, the combining valve is the ideal complement for turbines equipped with equally long service combustion hardware. This valve is water cooled to prevent coking of spools, valve seals, the internal fuel volume and the fuel distributor section.

Power Generation - Valve Monitor & Protection Systems

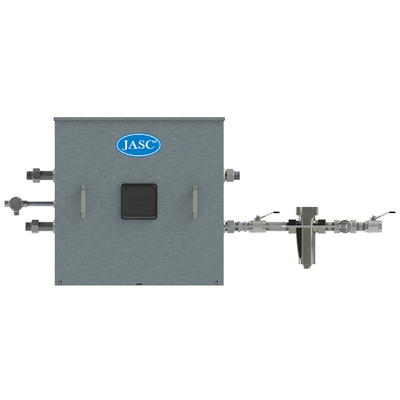

JASC - Fluid Sentry Monitor

Remotely Monitors And Reports Coolant Flow And Temperatures As Well As Piping System Integrity. A key component of JASC’s back-up liquid fuel system reliability design is the Smart Fluid Monitor. With cooling water piping infrastructure having a life expectancy of decades and turbine major maintenance intervals of every 4 to 5 years, the ability to remotely monitor the performance and integrity of the cooling system has become an important part of achieving improved liquid fuel system reliability.

Power Generation- Water Injection Valves

JASC - Water Injection Check Valve

This Water Injection Check Valve provides stable operation and can be operated continuously. It has high-temperature seals (Class 6 seal) that provide long-life sealing capability when the valve is not flowing water. Maintaining the Class 6 seal in this Water Injection Check Valve prevents the water system from evacuating during periods of inactivity. When the water injection system is activated, all of the water lines will be full; this, in turn, will prevent exhaust temperature spreads that tend to trip the turbine.

JASC - Model F-Class - Water Injection Check Valve

JASC’s redesigned F-Class water injection check valve now incorporates a metal to metal seat. This technology is well suited for use in systems which utilize liquid fuel and water purge. With a continuous service rating of 600°F, using our crushed seal adapters, this valve’s adjustable cracking pressure, corrosion resistance and built-in stability for elimination of high frequency oscillation make it the perfect upgrade for 7FA, 9FA and 9E turbines. Apply this simple upgrade to improve your turbine’s ability to transfer from gas to liquid fuel and back with this exciting new product. Contact JASC for more information.

Aerospace- Actuators

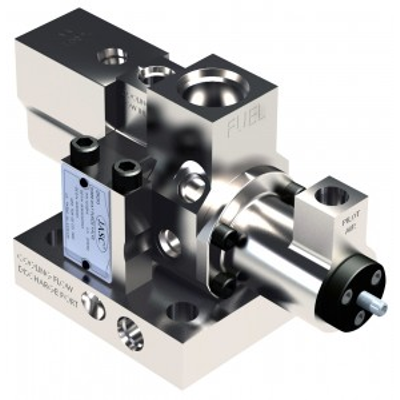

JASC - Inlet Guide Vane Actuator (IGVA)

The Inlet Guide Vane Actuator (IGVA) has a direct acting, 3-way clevis-type, servo valve used for actuation with an LVDT to provide position feedback. The servo valve fueldraulically drives the actuator rod. The Inlet Guide Vane Actuator is mounted on an aircraft Auxillary Power Unit (APU) and used to control the position of a load compressor’s inlet guide vanes. The IGVA has low hysteresis and threshold with low electrical power consumption.