Jay Khodiyar Machine Tools products

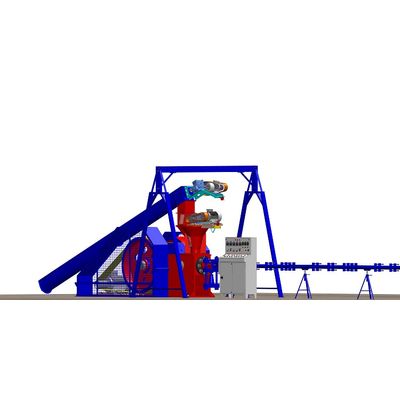

Briquetting Plant 65mm

Jay Khodiyar Briquettes plant 65 have earned a reputation to be an industry quality Worldwide. Briquettes plant 65 with diameter of 65mm, with production 600-800 kg / h, Different type of raw material like agricultural waste, forest waste can be used to make biomass briquettes press plant. This model is best suitable for achieving medium production capacity with minimum capital expenditure.Briquetting Press 75mm

Jay Khodiyar briquetting press 75 mm have earned a reputation to be an industry quality Worldwide. Briquettes Press JK 75 is best suitable for those users who have bulk density of raw material and industries like brick making, small scale industries for personal use having limited source of raw material. Likewise, our Briquetting Machine is best known to its performance and quality.Briquetting Machine 90mm

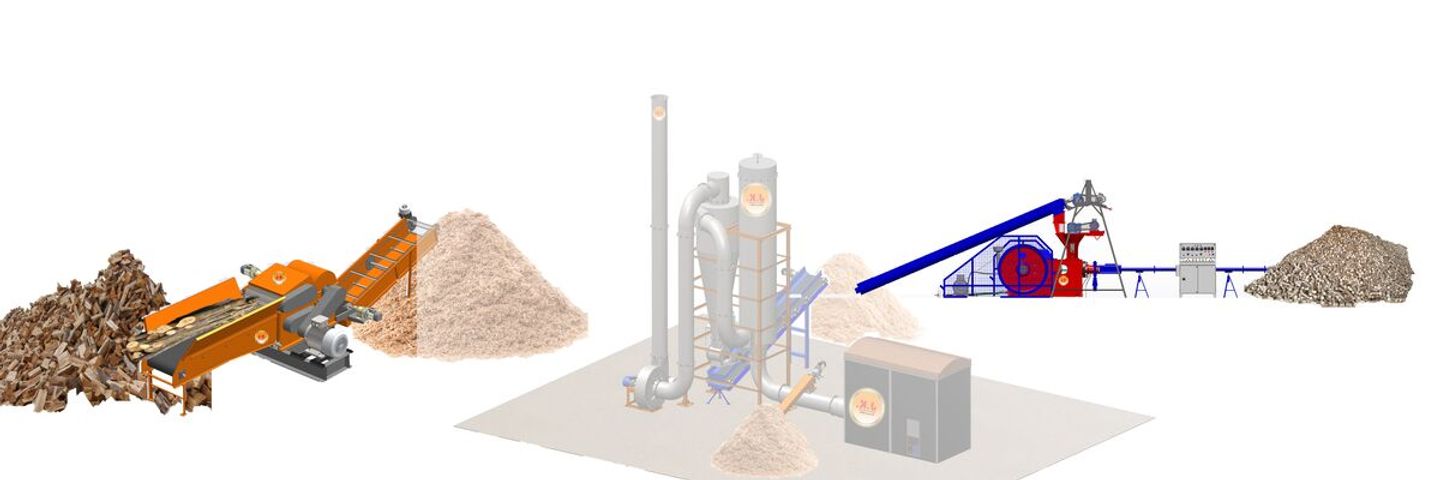

Briquetting Press Machine 90 mm The Biomass Briquetting Project is a sustainable initiative that converts agro and forestry waste into biomass briquettes press, promoting eco-friendly and renewable energy for a healthier environment and thriving economy. Join us in this green energy venture today! Using the Briquetting Machine, agricultural and forest waste can be converted into top-notch Biomass Briquettes press, devoid of binders or adhesives. These environmentally friendly briquettes offer a remarkable substitute for black coal and other fossil fuels, fostering sustainable heat generation practices. Process of Making Briquettes Press The machine is fed with dried and granulated raw material through an in-feed screw conveyor. Inside the machine, the kupy worm propels the material into the briquetting chamber. With a high-pressure of mechanical punch, biofuel briquettes are formed in the chamber without requiring any binder.Biomass Crushing Machine

The use of Biomass Crusher machine is employed to compress and chop raw material which is in the form of Agricultural waste, Forestry waste, and Municipal waste. In the process of producing Biomass Briquettes, the use of Biomass Crusher comes first. The raw material that is imported from various sources like Agricultural fields, Forest areas, and Piles of Garbage is first put into Biomass crusher or shredder Machine which makes the uneven stuff of raw material into small form.It is also known as wood shredder machine or shredder or cutter machine.

Biomass Chipper Grinder

Jay Khodiyar manufacturing Chipper Grinder machine with best quality and long life products. Chipper grinder Machine are basically used for cutting & chipping different raw material into desired size as per customer needs. The crusher cut the material into small pieces which helps to make material portable.

Briquetting

Briquettes Plant 65 MM

Briquettes plant 65 with diameter of 65mm, with production 600-800 kg / h, Different type of raw material like agricultural waste, forest waste can be used to make biomass briquettes. This model is best suitable for achieving medium production capacity with minimum capital expenditure. From the storage silo or screw conveyor the biomass is transferred to a feeder and then briquetted in a cylindrical shape. The flywheel is used to store kinetic energy to sustain continuous operation that requires a great amount of power. Also Know as briquette plant manufacturer suppliers & exporter, briquettes plant, briquetting plant equipment.