Jingjin Filter Press Group Co. Ltd. products

Filter Press

Jingjin - Automatic Locking Filter Press

Jingjin Environmental Protection Inc. founded in 1998.The company is a complex environmental protection service provider of filter outfit production, filter technology overall plan solution and environment protection project contraction and operation.It is also the vice-president unit of China Environmental Protection industry Association and the primary drafter of national standards for filter press and filer plates.The filter press’s production capacity and sales volume remain the largest worldwide for twelve consecutive years, and sells to 123 countries and regions.Jingjin trademark has been recognized as a ‘Famous Chinese Trademark’ by the State Administration for industry and Commerce of China, and is also protected by Madrid International Trademark Rgistration.Water Jiang, chairman of Jingjin was awarded National Labor Model and National Model Worker.

Jingjin - Belt Filter Presse

A belt filter press is a type of filter press that uses a continuous belt of filter media to separate liquids and solids. It is popular in various industries, including food and beverage, chemical processing, and wastewater treatment.

Jingjin - Energy Saving and Efficient Water Washing Vibrating Filter Press

The material of Jingjin frame is Q345B, which tensile strength is 1.4 times of Q235, it makes Jingjin filter press can be operate more safe and stable. The oil cylinder seat, pressing plate and thrust plate are formed by carbon dioxide protection welding.

Jingjin - Model Q345B - External Washing And External Discharge Vibrating Pressure Filter

The material of Jingjin frame is Q345B, which tensile strength is 1.4 times of Q235, it makes Jingjin filter press can be operate more safe and stable

The oil cylinder seat, pressing plate and thrust plate are formed by carbon dioxide protection welding. The main beam of Jingjin filter press is designed by adopting welded box construction, and manufactured by making use of submerged arc auto welding technology. All the spare parts that need painted are dealed with high speed centrifugal ball blast descaling and iron scale. After painting MIO epoxy build primer, paint acrylic polyurethane coating directly to make it have the best adhesion. It can save hundreds tons of putty every year, thus not only reduce the cost, but also protect the environment. More important, it improves the adhesion of the paint and antisepsis class of the filter press.

Jingjin - High Efficiency Vibrating Filter Press

Jingjin Environmental Protection Inc. founded in 1998.The company is a complex environmental protection service provider of filter outfit production, filter technology overall plan solution and environment protection project contraction and operation.It is also the vice-president unit of China Environmental Protection industry Association and the primary drafter of national standards for filter press and filer plates.

Filter Cloth

Jingjin - Model 108C Encryption - Filter Cloth

Jingjin Environmental Protection Inc. founded in 1998.The company is a complex environmental protection service provider of filter outfit production, filter technology overall plan solution and environment protection project contraction and operation.It is also the vice-president unit of China Environmental Protection industry Association and the primary drafter of national standards for filter press and filer plates.The filter press’s production capacity and sales volume remain the largest worldwide for twelve consecutive years, and sells to 123 countries and regions.Jingjin trademark has been recognized as a ‘Famous Chinese Trademark’ by the State Administration for industry and Commerce of China, and is also protected by Madrid International Trademark Rgistration.Water Jiang, chairman of Jingjin was awarded National Labor Model and National Model Worker,

Jingjin - Filter Cloth

Jingjin Environmental Protection Inc. founded in 1998.The company is a complex environmental protection service provider of filter outfit production, filter technology overall plan solution and environment protection project contraction and operation.It is also the vice-president unit of China Environmental Protection industry Association and the primary drafter of national standards for filter press and filer plates.The filter press’s production capacity and sales volume remain the largest worldwide for twelve consecutive years, and sells to 123 countries and regions.Jingjin trademark has been recognized as a ‘Famous Chinese Trademark’ by the State Administration for industry and Commerce of China, and is also protected by Madrid International Trademark Rgistration.Water Jiang, chairman of Jingjin was awarded National Labor Model and National Model Worker.

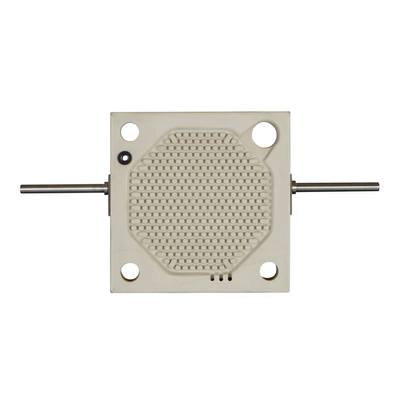

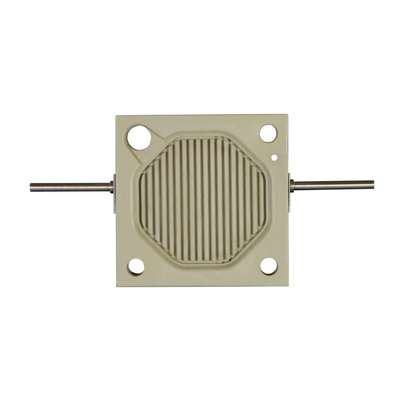

Filter Plate

Jingjin - Model 250 - Membrane Plate

We have three factories,and two is for the filter plate producing. Filter plate is the core part of the filter press.Different materials ,models and qualities will affect the whole machine’s filtration performance directly.Its feeding hole,filter points distribution (filter channel) and water discharge channels have different designs according to different materials.”JINGJIN” filter plate adopts imported TPE elastomer and high intensity PP, which make the filter plate not noly has the flexibility of the rubber plate, but also the tenacity and rigidity of the polypropylene plate that ensure the airtightness of the filter plate during pressing.All technical index of JINGJIN filter plate strictly complied with EU standard.The maximum membrane inflation pressure of “JINGJIN” high pressure PP membrane filter plates can be up to 4.0Mpa,which represents the most advanced level of the world.

Jingjin - Model 250 - Recessed Plate

We have three factories,and two is for the filter plate producing.

Accessory Equipment

Jingjin - Agitator

Agitators are widely used in chemical, pharmaceutical, food, mining, paper, paint, metallurgy, waste water treatment and other industries, suitable for agitating operation with liquid phase as the focus to achieve multiphase mixing including liquid -liquid, liquid -solid, gas - liquid and gas - liquid - solid and heat transfer, mass transfer and chemical reaction. In this agitating test-bed, different trough types have been adopted to match with agitators. Through the observation test of actual flow filed of fluid agitating and data test and collection, we have optimize the design and developed new practica propeller type in order to achieve the best effect of agitating with minimal power consumption under the full conditions, working.