John King Chains Limited products

Forged Chains

JOHN KING - Forged Link Chains

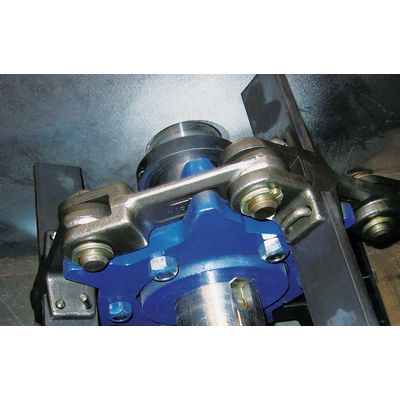

This series represents the leading product within the John King programme. Forged fork link chain has proven to be one of the most reliable conveying mediums offering a combination of versality, strength and abrasion resistance. These chains, originally of european origin, are now established worldwide. With a wide variety of materials, heat treatments and flight formats the chain is proven in both drag and enmasse handling.

JOHN KING - Forged Link Chains

Where extra wide flights are required the John King triple link is available allowing, in conjunction with the double on perimeters, three chain strands up to 3100 mm overall. In addition the “Double slot” allows for a versatile means or flight retention for both steel & plastic options. Retention can be either U clips or standard fasteners.

JOHN KING - High Manganese Wear Rail

The standard recommendation for forged chain wear rail is manganese steel, an austenitic structure, offering unique work hardening properties. In its rolled condition it offers a hardness value of 200-220 Bnh increasing up to 600 Bnh if the optimum conditions prevail.

Welded Steel Chains

JOHN KING - Equivalent Welded Steel Chains

John King order a unique range of welded steel chains dimensionally equivalent to M Series bush chains according to DIN8167. The chain offers all the benefits of the “offset” sidebar welded construction and can be accommodated in existing conveyors and operate on same sprockets. This allows the user a unique opportunity to improve reliability and service life without major alteration.

JOHN KING - Extra Heavy-Duty Welded Steel Chains

JOHN KING Extra heavy duty welded steel chains employ heavier link plates for increased wearing surfaces. The sizes and specifications ensure higher ultimate strength, superior impact resistance and extended service life. The addition of induction hardened sidebar surfaces, although available throughout the narrow series range, is typical in the XHD where sliding wear is often the major issue.

JOHN KING - American Standard Engineered Steel without Rollers

The smooth and stable flow of material through a process depends on the performance of the conveyor chain installed within the equipment. Bush class chains or steel knuckle chain are of the same construction as roller conveyor chain, but with the roller excluded. This series, with a reduced number of components, has proved to be particularly successful in high duty, high abrasion applications where lubrication is not possible. For many years KING steel bush chains have been proving performance in mill duty centrifugal discharge elevators within the more difficult applications encountered in the Cement and Steel Industry.

JOHN KING - Maxi Chains

This John Kings works standard includes a range of crank link steel bush chains that offer maximum versatility either in conveying or elevating applications. This series was originally developed to offer an all steel direct replacement for the Cast Bush and Pintle chains. Materials employed, with case hardened alloy steel pin and bush ensure reliable performance. The crank link construction is a more convinient and effective style. One link can be added or removed if chain length is altered. Any variety of attachments can be fabricated and welded to the base chain. This is generally K style but F, G and S are also popular.