- Home

- Companies

- Jordan Valve

- Products

Jordan Valve products

Pressure Reducing Regulators

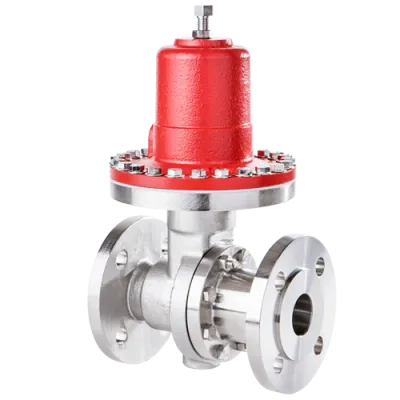

Jordan Valve - Self-Operated Sliding Gate Pressure Regulator

The Mark 60 Series is a versatile self-operating pressure regulator engineered for precise downstream pressure control. Suitable for a wide range of mediums including steam, water, oil, gas, and chemicals, the Mark 60 Series features sliding gate seats which contribute to its accuracy and durability. Available in sizes from 1/4 inch to 4 inches (DN8 to DN100), this pressure regulator can handle flow coefficients (Cv) up to 200 (Kv up to 172). Notably, the sliding gate design reduces wear and tear on the seats, enhancing service life and reliability. Various configurations are possible, including options in carbon steel, stainless steel, ductile iron, and bronze materials with different end connections like FNPT and flanged ends rated up to 300#. Ideal for applications demanding longevity and high performance in challenging environments.

Back Pressure Regulators

Jordan Valve - Self-Operated Back Pressure Regulator

The Mark 50 Series handles a broad range of applications including steam, water, oil, gas, air and chemicals. Excellent capacity and the sliding gate trim enables the Mark 50 to quickly and accurately regulate upstream pressure, preventing over-pressure situations.

Sliding Gate Temperature Regulators for Industrial Applications

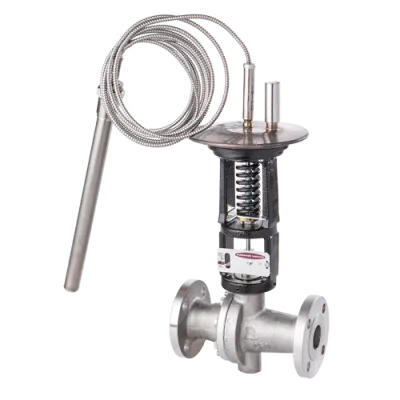

Jordan Valve - Self-Operated Valve

The Mark 80 Series is an entirely self-operated valve system that functions without the need for any external power source or supplementary expensive instrumentation. The operation of the valve is determined by temperature changes; the seats open or close as the bulb detects variations in temperature. This series exhibits high rangeability, managing flows between 10% and 90% of its rated capacity. It supports capillaries extending up to 100 feet (30 meters). Technical specifications include size options ranging from 1/4 inch to 2 inches (DN8 to DN50), various body materials such as Ductile Iron, Bronze, Carbon Steel, and Stainless Steel, and multiple end connection types including Threaded, Flanged, Socket Weld, and Butt-Weld. The valve has a flow coefficient (Cv) up to 30 (Kv up to 26) and features Jorcote seat material. The operational temperature range spans from -20°F (-29°C) to 450°F (232°C).

Gas & Tank Blanketing Regulators

Jordan Valve - Gas Back Pressure Regulator

The Mark 508 Series gas back pressure regulator presented by Richards Industrials is designed to handle low back pressure gas applications. This regulator works efficiently with the Mark 608 in tank blanketing systems, which are crucial for preventing tank over-pressurization by venting excess gas while maintaining a constant protective gas flow to keep the tank atmosphere stable. Its versatility extends to other low back pressure scenarios, facilitated by a body made from durable carbon steel or stainless steel. This regulator offers sizes ranging from 3/4 inch to 2 inches (DN20 to DN50), with connections available in threaded or flanged types. The diaphragm is constructed from Viton material, suitable for handling pressures up to 20 psi (1.7 bar). This device is critical in maintaining safe and optimal conditions in storage tanks and similar systems.

Industrial Control Valves

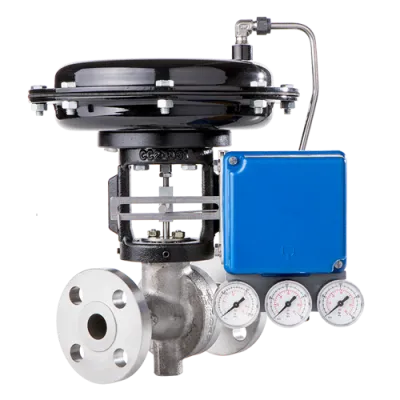

Jordan Valve - Sliding Gate Jorlon Diaphragm Control Valve

The Mark 70 Series is a line of pneumatically-operated diaphragm control valves that combine multiple spring actuators with the precision of the sliding gate seat for closer control and greater accuracy. A side or top-mounted positioner is available to overcome the normal hysteresis for a control valve and actuator and to ensure that the valve stem position is always directly proportional to the control valve command signal.