Jowa AB products

Oily Water Treatment Systems

Jowa - Model ODME 2005 - Oil Discharge Monitor System

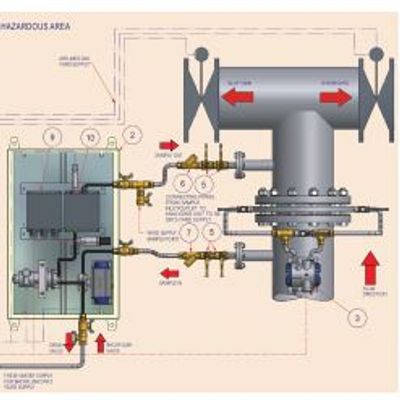

The requirements of the MARPOL Convention are that all oil tankers with a gross tonnage of 150 GRT and above must have an oil discharge monitoring and control system installed, incorporating an approved oil content meter, with a starting interlock and an automatic overboard valve control system. Oil Discharge Monitor consists of the following main parts:

Jowa - Model 3SEP - Oily Bilge Water Separator

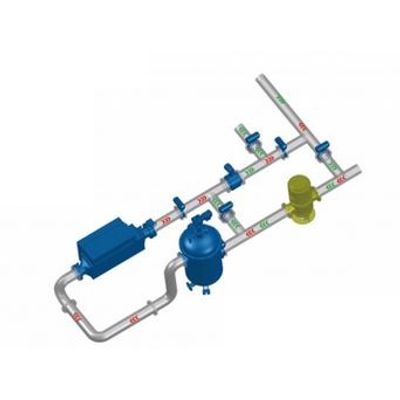

Jowa Oily Water Separator is available in five different capacities; 0.5 m3/h, 1.0 m3/h, 2.5 m3/h, 5.0 m3/h and 10.0 m3/h. The skid is optimised so that the footprint of the 3SEP OWS is as small as possible. The 1m3/h model pictured has a footprint of only 950 x 760mm.

Jowa - Model EBU - Emulsion Breaking Unit

The unit separates up to 80% of the water in the emulsion. The treated water is then fed to an MEPC 107(49) approved bilge water separator. The residue is pumped to the concentrated sludge tank. The system is operating automatically, in a step-by-step program (PLC controlled). The working principle is flocculation.

Fresh Water Treatment Systems

Jowa - Model 15-30T - RO Watermaker - Reverse Osmosis Watermaker

Reverse osmosis desalination is among the finest levels of filtration available. The RO membrane generally acts as a barrier to all dissolved salts and inorganic molecules. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 98% depending on factors such as membrane type, feed composition, temperature, and system design. Capacity is 15T or 30T potable water per day. Continuously monitoring and automatically divert the product flow depending on salinity value. Full production with a temperature between 6-35C° and TDS 35 000ppm (salinity). Unique design with top quality HDMI interface. User friendly touch screen and prepared for communication to ECR/AIS via PROFIbus, CANbus, MODbus and more.

Jowa - Model 3,2T-5,5T SEA - RO Watermaker - Reverse Osmosis Watermaker

Reverse osmosis desalination is among the finest levels of filtration available. The RO membrane generally acts as a barrier to all dissolved salts and inorganic molecules. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 98% depending on factors such as membrane type, feed composition, temperature, and system design. Capacity is 3,3T or 5,5T potable water per day. Continuously monitoring and automatically divert the product flow depending on salinity value. Full production with a temperature between 6-35C° and TDS 35 000ppm (salinity). Unique design with top quality HDMI interface. User friendly touch screen and prepared for communication to ECR/AIS via PROFIbus, CANbus, MODbus and more

Jowa - Model 3,2T-5,5T SEA - RO Watermaker - Reverse Osmosis Split System

JOWA RO Reverse Osmosis Fresh Water Maker produces excellent potable water using Reverse Osmosis technology. Reverse Osmosis desalination is among the finest levels of filtration available. The RO membrane generally acts as a barrier to all dissolved salts and inorganic molecules. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 98% depending on factors such as membrane type, feed composition, temperature and system design.

Ballast Water Management Systems (BWMS)

Jowa OceanGuard - Headway Ballast Water Management Systems (BWMS)

Advanced Electro-catalysis Oxidation Process (AEOP). By adopting electron excitation to special semiconductor material, highly Active Hydroxyl Radical (.OH) will be produced from water molecules. The Hydroxyl Radicals kill Micro-organisms, bacteria and viruses in water by destroying their cell membrane. system design. Capacity is 15T or 30T potable water per day. Continuously monitoring and automatically divert the product flow depending on salinity value. Full production with a temperature between 6-35C° and TDS 35 000ppm (salinity). Unique design with top quality HDMI interface. User friendly touch screen and prepared for communication to ECR/AIS via PROFIbus, CANbus, MODbus and more.

Waste Water Treatment System

Jowa - Model STP 2016 - Sewage Treatment Plant

The unit runs automatically with no operator attendance. It can be fed by gravity or a fully integrated vacuum unit can be fitted as an option. The unit’s bioreactor ensures optimum biological treatment with no offensive odours produced.

Metritape Level Gauging Systems Marine

Jowa - Metritape Gauging Systems

In response to the industry trend of integrating onboard instrumentation with a streamlined approach to system gauging, JOWA USA provides a family of Metritape tank level gauging systems including: Vanguard IV, Sentry IV, DeckMaster IV, Metricircuit 60,000 Metrimeter, and Metriguard Tank Monitor. Utilizing our Metritape technology, the systems are cost-effective, reliable, low-maintenance and stable. All systems offer computer-based centralized control and monitoring. Independent high alarm can be achieved by installing two resistance-tape sensors in a single deck penetration. These systems can also include temperature detection and IG/tank pressure monitoring.