- Home

- Companies

- K2 Castings Inc

- Products

K2 Castings Inc products

Pin Protectors

Because they crush and densify materials in the shredding chamber, Pin Protectors perform a similar role to hammers in the shredding chamber. No only do they shield hammer pins, they reduce wear and tear on rotor disks. Pin Protectors also add vital mass to the rotor to preserve kinetic energy input by the motor (sometimes thought of as the “flywheel effect”). All K2 Casting Pin Protectors are cast in an ISO 9001 foundry from virgin materials with strict attention to detail. The result is a long-wearing, durable wear part that reduces casting-related downtime.

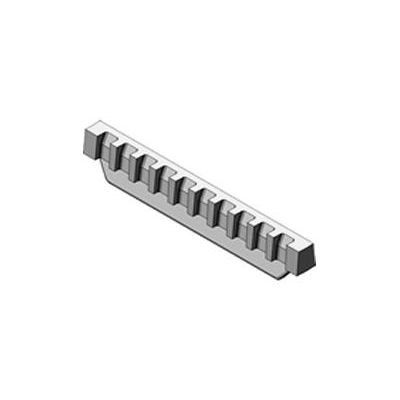

Anvils, Breakers, Cutter Bars, and Liners

Whether you need replacement cutter bar sections or an outer box liner, K2 Castings has wear parts that fit most machines. Cast in an ISO 9001 modern factory from virgin materials, K2 Castings wear parts wear long.

Caps and Hammer Pins

K2 Castings has a full line of replacement wear parts for most shredding machines. Our spider rotor helmet caps and end disk caps are cast using our proprietary heat treat – for a tough and durable wear cap. We also supply durable hammer pins and roof liner pins for many machines. Our top performing pin shafts deliver value and performance.

Hammers

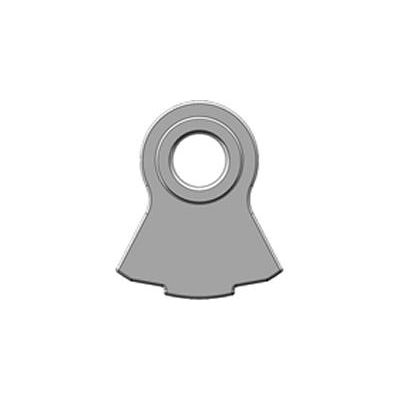

Bell-Shaped

These bell-shaped wear hammers run longer and deliver better ferrous tons out than many competing castings. You will notice the difference! We have hammer patterns for common metal shredders up to 10,000 HP.

Grates

Shredder Grates

A durable and excellent value, K2’s self-supporting manganese grates hold up to the rigors of shredding while delivering consistent performance. Also extremely tough and durable, our alloy grates are manufactured using strict quality controls. Radiographic and ultrasonic testing ensures quality and performance in your mill. For shredders with grate supports, our alloy steel grates / grids have proven themselves from Missouri to Melbourne.