- Home

- Companies

- Kanadevia Inova AG

- Products

Kanadevia Inova AG products

Technologies & Solutions - Waste to Energy

Kanadevia Inova - Hazardous Waste Treatment System

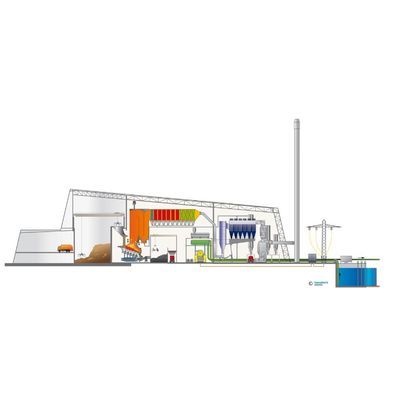

Thermal Treatment – a safe, efficient and proven technology. Treating hazardous waste is about the safe incineration (destruction) of the dangerous material contained in the hazardous waste. Moreover, issues such as the circular economy and energy recovery are also increasingly important. To incinerate hazardous waste, a higher temperature of 1,100 °C must be ensured compared to the 850 °C which must be maintained for municipal waste treatment. With a few exceptions, the rotary kiln with a secondary combustion chamber is used as a combustion system. It has proven itself in practice with more than fifty years of operational experience. Installations for hazardous waste are a special segment in the thermal treatment of waste. Each plant has its requirements and requires individual planning. Kanadevia Inova is your professional partner – from the concept phase to engineering, construction to commissioning and maintenance throughout the plant’s entire life cycle.

Kanadevia Inova - Flue Gas Treatment System

Incinerating waste produces exhaust gases laden with diverse pollutants. Different processes are used to remove these pollutants before the purified flue gas leaves the plant safely through the stack. For decades Kanadevia Inova has been doing research into flue gas treatment and developing new and effective treatment systems. We harness internal synergies to optimally match and combine our combustion and flue gas treatment equipment. The numerous processes that have emerged can be used individually or together to create high-performance integrated systems. The appropriate flue gas treatment approach is chosen in close consultation with the client. The selection criteria include regulatory air pollution limits, the client’s expectations regarding the energy efficiency of the plant, restrictions on waste water discharge, and the space available on site – to name only a few.

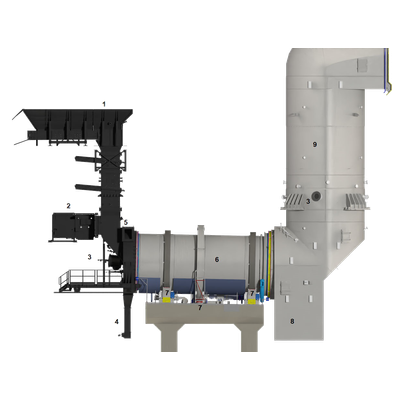

Kanadevia Inova InovaRe - Bottom Ash Material Recovery and Recycling

InovaRe by Kanadevia Inova: Efficient Material Recovery from Waste. Recovering metals from bottom ash is an aspect of urban mining that is becoming increasingly significant for the operators of WtE plants. As well as enabling valuable materials such as copper and aluminium to be recycled profitably from the bottom ash, it also saves huge amounts of CO2. Recycling aluminium from bottom ash requires just 10% of the amount of the energy consumed in primary production. In addition to the tried-and-tested wet discharge process, Kanadevia Inova also offers InovaRe, a complete modular solution for the efficient recovery of materials from bottom ash. Developed in-house, it is suitable for both wet and dry discharge.

Technologies & Solutions - Waste to Energy - Integrated Flue Gas Treatment Systems

Kanadevia Inova - Fabric Filter

Kanadevia Inova’s fabric filter is a product developed by Kanadevia Inova to remove solids (dust) from the flue gas. It is a physical separation process where the solids are filtered out at the surface of a gas-permeable fabric. If the fabric filter is used in a dry sorption (the XeroSorp process) or semi-dry sorption (Kanadevia Inova SemiDry) process, a filter layer of reagents and fly ash forms on the filter bags, where the separation of pollutants takes place.

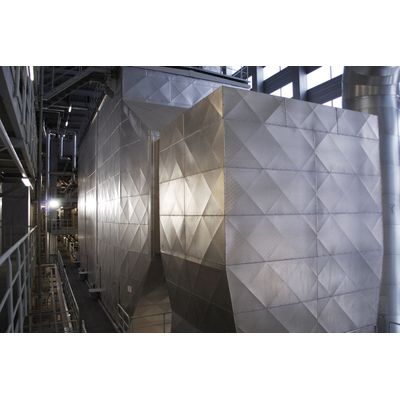

Kanadevia Inova - Electrostatic Precipitator System

In an electrostatic precipitator particles are ionised – in other words electrostatically charged – and then separated out under the influence of an electric field. The electrostatic precipitator, comprising two or three electric fields, is usually placed directly downstream of the boiler.

Kanadevia Inova XeroSorp - Dry Sorption System for Acid Gas Neutralisation

In Kanadevia Inova’s XeroSorp dry scrubbing process, corrosive acid gases (for example HCl, HF and SO2) are neutralised with the help of adsorption additives. The term “xero” is a Greek prefix derived from the word “ξηρός” (xērós), meaning “dry”. As the name suggests, the process does not involve the introduction of any water at all. Instead we use two different adsorption additives for neutralisation: hydrated lime and sodium hydrogen carbonate (commonly known as sodium bicarbonate).

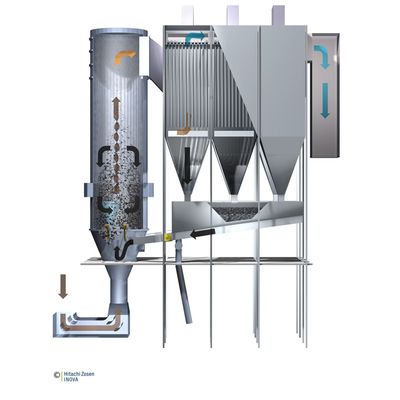

Kanadevia Inova SemiDry - Semi-Dry Sorption System for Acid Gas Neutralisation

The Kanadevia Inova SemiDry system involves a semi-dry sorption process employing the principle of the circulating fluidised bed. Hydrated lime is injected into the fluidised bed reactor to neutralise corrosive acid gases. The temperature in the reactor is key to the sorption process. To achieve the ideal reaction temperature (typically 145°C), water is sprayed into the reactor simultaneously. In addition to regulating the temperature, the water reactivates the recirculated residues, optimising the separation efficiency of the process.

Kanadevia Inova - Wet Scrubber System

Wet scrubbing is the most effective method for removing acid gases from even heavily burdened flue gases. It achieves the lowest emissions, and is also excellent when it comes to removing particulates and aerosols. Wet scrubbers consist of several stages, each of which fulfils a particular purpose: separating out specific pollutants, saturating flue gases, or extracting heat. Each scrubber stage therefore features specific equipment, for example nozzles, liquid distributors, packed beds, ringjets, droplet separators, etc. Thanks to different forms of intensive contact of the flue gases with water, pollutants are captured and separated extremely thoroughly.