- Home

- Companies

- Kerui Petroleum

- Products

- Drilling Equipment Series - Conventional Land Drilling Rig

- Drilling Equipment Series - Truck Mounted Drilling & Workover Rig

- Oil & Gas Stimulation Equipment - Fracturing Spread

- Oil & Gas Stimulation Equipment - Coiled Tubing Unit

- Oil & Gas Stimulation Equipment - Nitrogen Generation Unit

- Oil & Gai Stimulation Equipment - Liquid Nitrogen Pumper

Kerui Petroleum products

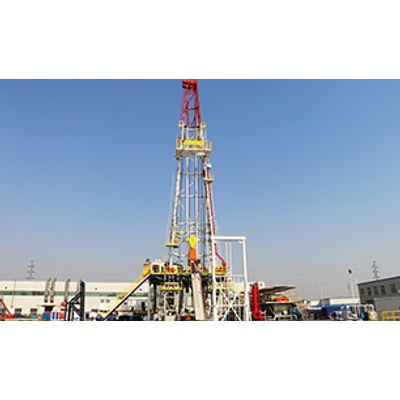

Drilling Equipment Series - Conventional Land Drilling Rig

Kerui - Model 750HP/1700kN - Conventional Land Drilling Rig

LThe land drilling rig is usedfor oil and gas exploration and development on wells that are I600~3000m (drill pipe 4 1/2") or I500~2500m (drill pipe 5") deep. Max. drilling depth 3,000 m. The rig with modular design and compact structure. The rig driller control cabin with electric & air & hydraulic oil control, which can reduce labor intensity and improve the working environment. The rig driving model could be VFD, mechanical or combined drive, client could require the rig model. The rig substructure model could be box-on-box or swing-up, with compact structure. The generator house with noise-insulation design, to reduce environment pollution and human harm.

Drilling Equipment Series - Truck Mounted Drilling & Workover Rig

Kerui - Model 150HP/500kN-45OHP. - Truck Mounted Drilling & Workover Rig

Power system, drawworks, mast, travelling system and transmission system of the workover rig are mounted on the self-propelled chassis, and the rig has features of easy transportation, low moveable cost, reliable performance, high operating load, high cross-country power and others: Basis parameters and the overall design of the workover rig conform to GB.`T 23505-2009 and SY/T 6724-2008; Mast, substructure, travelling block, hook, crown block, swivel, rotary table, mud pump and other main equipment conform to API specification and HSE requirements and are marked with API monogram: Utilize mature, reliable and practical advanced technology and use imported parts for diesel engine, transmission case, control valve and other critical components.

Oil & Gas Stimulation Equipment - Fracturing Spread

Kerui - Model KTYL - Fracturing Pumper

Fracturing pumper is the main unit of the whole spread, it is used to inject high pressure fracturing fluid in large amount to crack the stratum and leave the proppant in the fissure. The fracturing spread includes the fracturing pump unit, the blender, the manifold unit, the data van and auxiliary equipment. Fracturing pumper is mainly used for fracturing operation of deep well, medium deep well and shallow well. The devices are capable of single operation and series operation.

Oil & Gas Stimulation Equipment - Coiled Tubing Unit

Kerui - Model KTLG - Truck Mounted Coiled Tubing Unit

The basic function of CTU is to trip in and out the coiled tubing through tubing or casing in the oil or gas well during operation, and wind the coiled tubing round the reel for easy transportation. It can ensure efficient and lasting operation in the field of well sand washing, well flushing, acidizing, nitrogen gas lift, induced flow, well completion, well killing, well fishing, well logging for highly-deviated well and horizontal well, coiled tubing perforation, sand consolidation and sand control and well sealing. Main application: sand washing, well flushing, nitrogen gas lift, wax removal, well completion, velocity string, drilling and milling bridge plug, well fishing, well logging for highly-deviated and horizontal well, sand blasting perforation, cement injection for well sealing, annulus fracturing, drilling.

Kerui - Model KTLG - Trailer Mounted Coiled Tubing Unit

The basic function of CTU is to trip in and out the coiled tubing through tubing or casing in the oil or gas well during operation, and wind the coiled tubing round the reel for easy transportation. It can ensure efficient and lasting operation in the field of well sand washing, well flushing, acidizing, nitrogen gas lift, induced flow, well completion, well killing, well fishing, well logging for highly-deviated well and horizontal well, coiled tubing perforation, sand consolidation and sand control and well sealing. Main application: sand washing, well flushing, nitrogen gas lift, wax removal, well completion, velocity string, drilling and milling bridge plug, well fishing, well logging for highly-deviated and horizontal well, sand blasting perforation, cement injection for well sealing, annulus fracturing, drilling.

Oil & Gas Stimulation Equipment - Nitrogen Generation Unit

Kerui - Model MZD - Offshore Skid Mounted Membrane Separation Nitrogen Generation Unit

The membrane separation nitrogen generation technique separates air by the feature that different gas has different speed of penetrating the membrane. Oxygen, carbon dioxide and water vapor can rapidly penetrate the membrane, but nitrogen would be purified as it is not easily penetrating the membrane. With a small size, light weight, wide applicability and high separation efficiency, easy to maintain, the features of nitrogen membrane technology have been widely used in many industries. The complete set of membrane separation nitrogen generation equipment consists of air compressor, air processing system, membrane separation nitrogen generation system, nitrogen supercharger system, and central control system, skid-mounted cabinet and auxiliary system.

Kerui - Model MZO - Onshore Skid Mounted Membrane Separation Nitrogen Generation Unit

The membrane separation nitrogen generation technique separates air by the feature that different gas has different speed of penetrating the membrane. Oxygen, carbon dioxide and water vapor can rapidly penetrate the membrane, but nitrogen would be purified as it is not easily penetrating the membrane. With a small size, light weight, wide applicability and high separation efficiency, easy to maintain, the features of nitrogen membrane technology have been widely used in many industries. The complete set of membrane separation nitrogen generation equipment consists of air compressor, air processing system, membrane separation nitrogen generation system, nitrogen supercharger system, and central control system, skid-mounted cabinet and auxiliary system.

Kerui - Model MZD - Onshore Truck Mounted Membrane Separation Nitrogen Generation Unit

The membrane separation nitrogen generation technique separates air by the feature that different gas has different speed of penetrating the membrane. Oxygen, carbon dioxide and water vapor can rapidly penetrate the membrane, but nitrogen would be purified as it is not easily penetrating the membrane. With a small size, light weight, wide applicability and high separation efficiency, easy to maintain, the features of nitrogen membrane technology have been widely used in many industries. The complete set of membrane separation nitrogen generation equipment consists of air compressor, air processing system, membrane separation nitrogen generation system, nitrogen supercharger system, and central control system, skid-mounted cabinet and auxiliary system.

Oil & Gai Stimulation Equipment - Liquid Nitrogen Pumper

Kerui - Model LNP - Liquid Nitrogen Pumper

With professional technology for direct fired and heat recovery liquid nitrogen pumping unit, skid-mounted, trailer-mounted and truck-mounted are all available. The conventional model specs are 90k, 180k, 360k, 540k, 660k, 740k and 1100k, non-standard requirements are available for customers, with rated pressure levels as follows: 7000psi, 10000psi. 15000psi.