Keyland Polymer Material Sciences products

Keyland Polymer - UV Powder For Metal

Metal is an ideal candidate for UV cured powder coatings, with formulations for both ferrous and nonferrous metals. UV powder’s low melting temperature and fast finishing allow pre-assembled metal parts containing heat sensitive materials (gaskets, plastics, and electronics) and large mass metal parts to be finished. Some metals require specific pretreatments prior to metal finishing. We have worked with various types including: zinc phosphate, iron phosphate, and zirconium. Every finishing system is unique, please contact us to discuss. With growing environmental regulations and sustainability goals, many companies have approached us looking for a new or replacement system for their existing solvent-borne coating line. A UV cured powder coating system offers excellent performance characteristics without the negative environmental impacts.

Keyland Polymer - UV Cured Powder Coating for Wood Substrates

Keyland Polymer Material Sciences specializes in UV cured powder coating solutions specifically designed for wood-based substrates such as MDF, hardwoods, and plywood. These coatings offer considerable advantages including low process temperatures which minimize thermal degradation of wood, preventing issues such as cracking and grain raise. The company's expertise includes custom powder development tailored to match RAL and Pantone standards, alongside various finishes. Their in-house labs enable precise formulation and testing to meet specific performance requirements, ensuring that coatings adhere effectively. This process results in a smooth, durable finish suitable for a variety of wood species without compromising structural integrity, catering to both aesthetic and functional needs.Substrates - Plastics

Keyland Polymer - UV Cured Powder Coating on Plastics

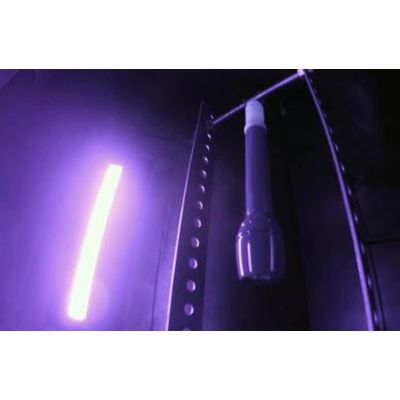

UV cured powder coating requires only enough time and heat to melt the powder, an example being 130°C at 1-2 minutes, followed by UV cure. Once the part is exposed to UV light it is instantly cured. The process speed and low temperatures allow plastics to be successfully finished without melting or deforming the part. Since plastic is a non-conductive material, a primer is used to promote adhesion on the surface of the part before powder application.

Keyland Polymer - UV Cured Powder Coating on Composites

Demand for energy efficient, electric and alternative use vehicles is accelerating the use of lightweight materials. Manufacturers are switching from steel and aluminum to carbon fiber which is lighter, stronger, and more resistant to corrosion than metals. Unlike metals, carbon materials do not require corrosion protection, but they do need to be finished for aesthetics and appearance. The fast process time and low temperatures (example 130°C at 1-2 minutes) followed by instant UV cure, ensures that the integrity of the composite material is not compromised.