Kingfisher Industrial Ltd products

Wear Resistant Linings - Ceramic Range

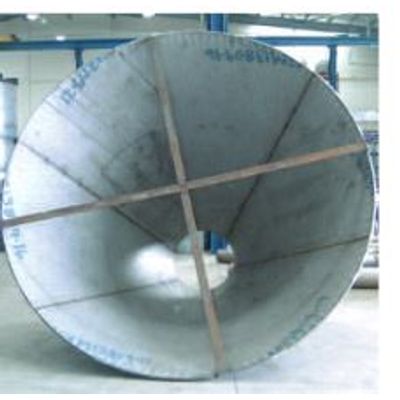

Kingfisher - High Alumina Ceramic Lining System

K-ALOX has an excellent rating for resistance to all forms of abrasion, with a hardness of 9 MOHS and the ability to withstand very high operating temperatures. K-ALOX also has excellent resistance to corrosion and chemicals.

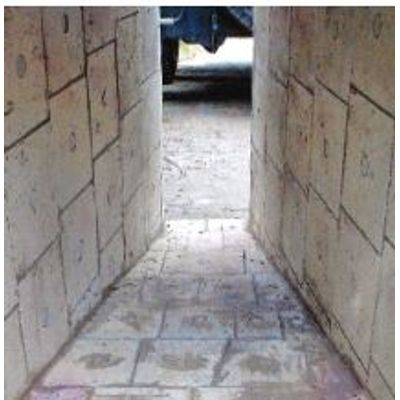

Kingfisher - Fused Cast Basalt Lining System

This material is ideal for applications in conveying and storage systems requiring high resistance to friction induced abrasion. K-Bas has an extremely hard and smooth surface, resistant to most acids and alkalis, and can be used in temperatures up to 350°C (662°F).

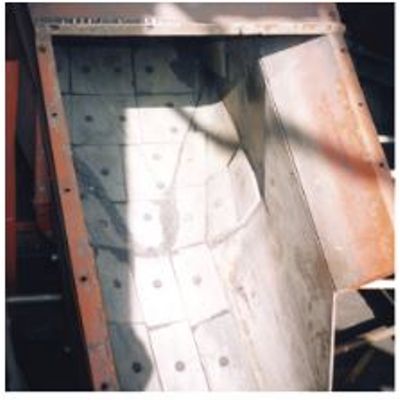

Kingfisher - Monolithic Ceramic Lining System

KingfisherK-CAST is applied by trowel or by casting to provide a highly flexible solution to a wide variety of abrasion induced problems. The material offers excellent heat resistance as well as qood impact and sliding induced abrasion resistance.

Kingfisher - Silicon Carbide Ceramic Lining System

K-SIL has excellent resistance to abrasion and corrosion with high resistance to thermal shock. Two forms of K-SIL are available, both of which may be cast or machined to suit the application.

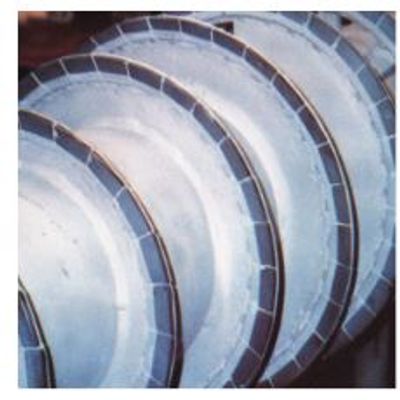

Kingfisher - Fused Corundum Lining System

K-ZAS is rated at 9 MOHS and is ideally suited to the protection of plant suffering from severe abrasion and erosion. The material also has a high resistance to thermal shock. The raw materials used for the manufacture of our K-ZAS lining material are zirconia, alumina and silicon which are crushed, screened and fed into an electric arc furnace where it is smelted at 1450°C. At this stage the minerals are converted into a molten state and cast into moulds. These components remain in the moulds and are placed into an annealing chamber where dependant on the volume of the casting determines what duration of heat treatment is required, where at the end of this process results in a material with characteristics of extreme abrasion resistance as well as resistance to high thermal stresses.

Wear Resistant Linings - Metallics

Kingfisher - Chromium Carbide Deposit Lining System

K-CLAD chromium carbide deposit is used to protect plant and equipment from impact and sliding induced abrasion associated with both light and heavy industrial processes.

Kingfisher - Ferritic Stainless Steel Lining System

K-FLOW is particularly suited to applications where protection is required from a combination of sliding and friction induced abrasion along with the need to keep bulk solids flowing.

Kingfisher - Ni Hard Cast Lining System

K-HARD cast products and linings are used to protect plant and equipment from crushing, impact and sliding induced abrasion associated with handling or conveying abrasive bulk solid materials.

Kingfisher - Hardened Steel Lining System

K-PLATE series of wear resistant steel is produced with a high carbon content and is manufactured in traditional steel mills used to convert iron into steel. Once the steel has been produced in slab form, the form is subjected to a process of continual heating, rolling, re-heating and further rolling under extreme pressures and water cooling. This process gives K-PLATE its unique hardness, being 400. 450 or 500 BHN respectively, where il will maintain thai hardness up to 275°C before its superior wear properties begin to wain due to the annealing process associated to heating plate.

Wear Resistant Linings - Polymer

Kingfisher - Epoxy Resin Lining Systems

As the material is supplied in paste form with a hardness rating to 6 MOHS it is capable of application to a wide range of surfaces. K-KOTE WRS has good resistance to abrasion, chemicals and corrosion and may be finished to provide a flow promoting surface.