- Home

- Companies

- KLINGELNBERG Group

- Software

KLINGELNBERG Group software

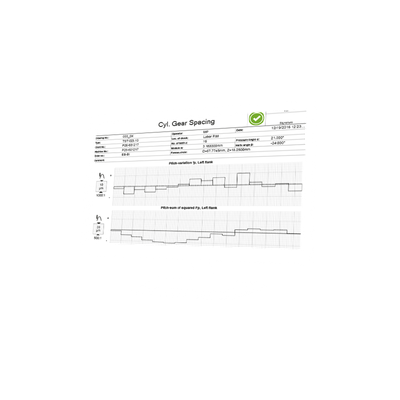

KLINGELNBERG - Cylindrical Gear Software

Klingelnberg's cylindrical gear software is a pivotal tool within gear measuring technology, establishing itself as an industry standard across the globe with thousands of installations. Its role is integral to measuring center operations, providing accurate, timely measurements with robust software support. By accommodating a diverse array of evaluations, the software adheres to both national and international standards and tolerance fields. It is adept at assessing corrected gear teeth, including crowned, conical, and bevel gears, as well as executing advanced measurements for twist, root, and tip relief, along with topography assessments. The system also features workpiece axis determination, rolling path calculations based on mating gear data, and secure measurement curve archiving. The software serves as the backbone for the Closed Loop system, allowing for seamless integration of optional modules tailored to complex measuring tasks, such as interrupted tooth traces and segment gearing analysis, thereby enhancing measurement precision and functionality.

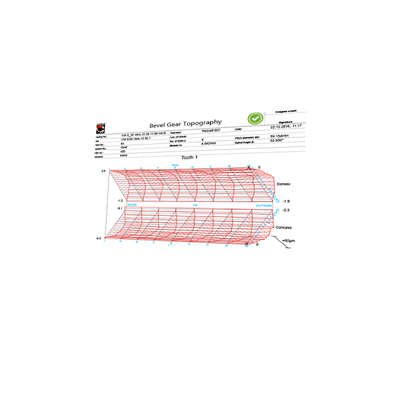

KLINGELNBERG - Bevel Gear Production and Measurement Software

Klingelnberg offers comprehensive IT and software solutions designed for the complete bevel gear production process. Their flagship development and design software, KIMoS, facilitates efficient data creation and management for spiral bevel gear manufacturing. This program integrates seamlessly with multiple machines in a Windows NT network, ensuring tight linkage between development and production, thus optimizing the production management process. KIMoS supports all Klingelnberg machines through a universal data interface. Additionally, the METEORIT software specializes in measuring KIMoS-calculated blades, supporting nearly all blade systems and enabling precise corrections on Oerlikon blade grinding machines. Klingelnberg's precision measuring centers ensure accurate spiral bevel gear testing through detailed evaluations of flank topography and pitch based on international standards. The KOMET5 program provides an automatic closed-loop system, allowing production control and machine setting corrections, achieving remarkable precision improvements measured in micrometers.KLINGELNBERG - Tool Measurement Software

Klingelnberg offers advanced tool measurement software as part of its comprehensive solutions for gear cutting tools, ensuring safe and precise measurement processes. This software, specifically developed for use on Klingelnberg precision measuring centers, supports the complete measurement of various tool profiles, including hobs, shaving cutters, broaches, and generating cutters. Klingelnberg's legacy dates back to the 1980s when it was a leading manufacturer of high-precision hobs, equipping it with specialist knowledge that benefitted both tool users and manufacturers. The company's collaboration with established partners in the tool industry has enriched its software with practical, process-reliable solutions. Klingelnberg's tool measurement software is favored by numerous experts and tool manufacturers for its reliability and effectiveness in tool maintenance and process optimization across industries.

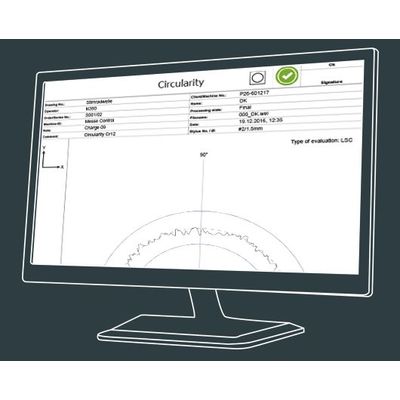

KLINGELNBERG - Precision Measuring Centers Software for Rotational Symmetric Workpieces

Klingelnberg offers sophisticated software modules for precision measurement centers designed to accommodate rotationally symmetric workpieces. Leveraging high-level systematization using elements like cylinders and cones, the software allows for the integration and evaluation of grooves in adapters and spline shafts. It supports seamless interaction with cylindrical and bevel gear software through intuitive drag-and-drop functionality. Among its robust capabilities, the software can conduct comprehensive measurements including grinding cutouts and root radiusing, thanks to its innovative scan elements. Additional modules extend its versatility to applications like testing of pointed splines, gearshift sleeves, and crankshafts, alongside advanced measurement techniques for camshafts, ensuring precision with Fourier analysis and graphical displays. This suite allows operators to handle measurements on concentric surfaces and even complex synchronous gears with ease, providing a fully automated approach to intricate dimension, form, and position assessments.

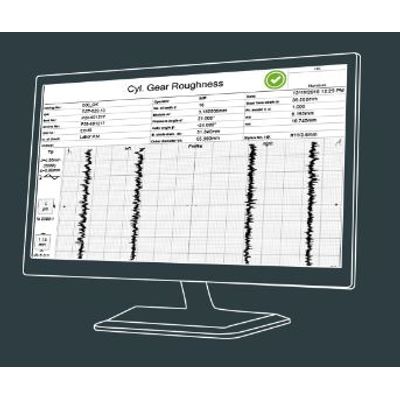

KLINGELNBERG - Roughness Measurement Software with Roughness Measurement

KLINGELNBERG offers advanced precision measuring centers in their P-series, which are equipped with high-precision roughness measurement devices. These devices enable fully automated integration into gearing and coordinate measurements, allowing all measurement processes to be completed in one clamping. The precision CNC-controlled procedures ensure a reproducibility of 0.01 µm, making it suitable for measuring intricate structures on gear teeth as small as module 0.9. The innovative design of the miniature roughness probe maximizes contact with the gear surface, providing precise measurements even on barrel-finished teeth. The evaluation is presented in detailed reports containing graphs and the roughness parameters crucial for assessing gear quality. The software offers customized solutions tailored to various measurement needs, including angled probes for bevel gear measurements. It ensures high precision even in challenging shop-floor environments, contributing to improved manufacturing accuracy and efficiency.