- Home

- Companies

- KLT Carbide Co.,Ltd

- Products

KLT Carbide Co.,Ltd products

Hard-Surface Coating

KLT Carbide - Hard-Surface Coating

KLT Surface Engineering Technology Center of KLT CARBIDE CO.,LTD was established in 2012, dedicated to the research and promotion of various surface engineering technologies.

Carbide Bushes

KLT-Carbide - Water Shaft Sleeve

Shaft sleeves coated with wear-resistant and corrosion-resistant coatings on stainless steel:

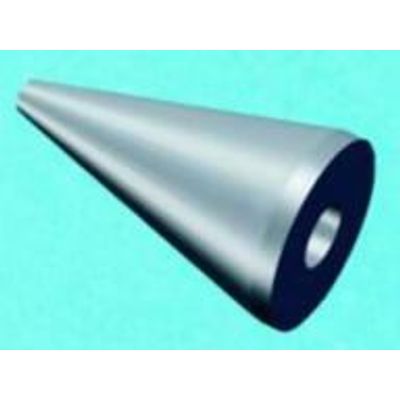

KLT-Carbide - Oil Shaft Sleeve

Carbide shaft sleeve plays Ihe role of positioning or protecting the shaft on the rotating shaft to prevent shaft wear. It lias the advantages of good wear- resistance, small friction coefficient, good toughness and long service life. It is widely used in sliding parts of various machines, such as motors, centrifugal pumps and protectors of submersible electric pumps for automatic mechanical equipment, hydraulic cylinder guide sleeves and oil extraction equipment.

Carbide Nozzles

KLT-Carbide - Nozzles

Carbide nozzles, also known as water holes, are mainly used for drilling lools such as PDC bits and cone bits for oil and gas drilling. Drilling fluids are used to wash, cool, lubricate drill teeth, assist rock breaking and clean bottom hole cuttings. It has high liardness, wear resistance and corrosion resistance, mainly used in tire industrial and milting environment of high pressure, vibration and high-speed erosion of sediment. The environment of these kinds of mine is very easy to cause erosion wear, which is one of the important reasons foi the damage and scrap of maclrineiy and equipment aird their parts. In order to ensure tire long-term, efficient and stable use of cemented carbide nozzles, a special anti-erosion sleeve is customized for the wear formation.

KLT-Carbide - Sand Nozzle

Carbide nozzle has a series of excellent properties such as high hardness, wear resistance, good strength and touglmess. heat resistance and corrosion resistance, especially its lugh hardness and wear resistance, winch remain basically unchanged even at 500 °C, and still keep high hardness at 1000 °C. Advantage: Corrosion resistance, long service life, excellent performance, high cost performance, not easy to wear.

Carbide Valve Parts

KLT-Carbide - Valve Ball and Valve Seat

Carbide valve balls and seats have a series of advantages, such as high hardness, high wear resistance, excellent corrosion resistance and high pressure resistance. They are widely used in petroleum and natural gas pumps, ore, minerals, construction and surface mining tools. Carbides made of titanium, cobalt and nickel can be selected according to different industries and mines. The production and processing of stainless steel and ceramics can also be provided.

KLT Carbide - Valve Parts

Carbide valve needle and spool: designed according to API6A standard, mainly used for wellhead oil (gas) derrick equipment, oil and natural gas flow control pump, and fluid flow control under harsh conditions. The medium is mainly composed of gas, water, oil. sand, wax, gum, asphalt and other components. It has high precision, high hardness, high wear resistance and other superior mechanical properties.

Carbide for Mining

KLT Carbide - Buttons

The carbide button bits for drill and oil field bits are made of tungsten carbide and cobalt powder by precise mixing, wet grinding, spray granulation, high precision alloy mold and TPA automatic precision press, and unpolled pressure sintering furnace for integrated sintering. After passivation (fine grinding), the products are produced. We can produce and supply according to the relevant product standards and our company`s samples. At the same time, we can also customize special size products according to the processing needs specified by customers. Spherical Buttons, Conical Bullous. Spoon Buttons. Eccentric Wedge Buttons. Wedge Buttons. Flattop Buttons. Milling Buttons. Cutting Buttons. PDC Substrate Tips and so on

Carbide Sealing Ring

KLT-Carbide - Sealing Ring

Carbide precise seal ring features excellent material, advanced production teclmology. stable mechanical performance, and high wear resistance and corrosion resistance, mainly used in sewage pump, mine drainage pump, centrifugal pump, centrifuge, shiny pump and mud pump. Precise sealing rings of different materials can also be used in different industrial and mining environments such as high speed rotation, high pressure, high (low) temperature, acid, alkali corrosive gas and liquid. Note: Material and structure design can be carried out according to customer drawings and usage requirements.

Carbide for Sand Mills

KLT Carbide - Special Sealing Ring for Bead Mill

The special sealing ling product for bead mill is grinded with minim dimensional tolerance. Rare anti-corrosion elements are added to the process formulation to make the sealing performance more durable. A same time, it has good strength and impact toughness, excellent wear | resistance. Ions service life, strong hardness and high flexural strength.