Krones AG products

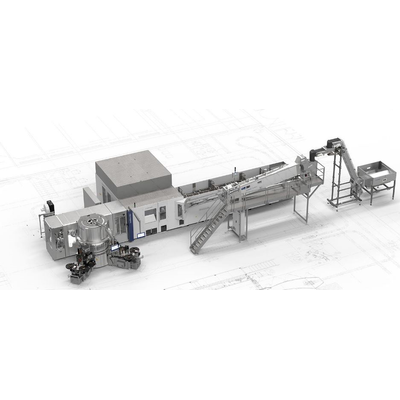

Filling and Packaging Technology - Bottling Filling Line Machine for PET Containers

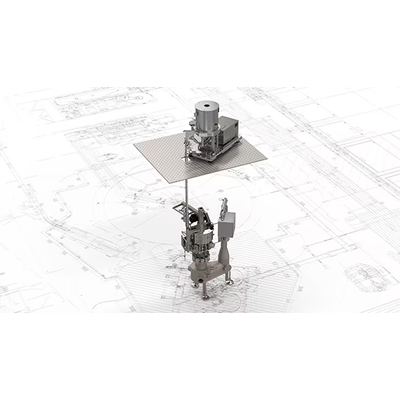

Krones - Model Aircontronic MSM - Detection System for Foreign Particles

A returnable container can experience many things between two cycles – and not all of it is pleasant. This is why it is all the more important to play it safe before refilling it again. Could there potentially be a substance in the container that the bottle washing system was unable to remove? The Aircontronic has the answer. With its detection systems, it can reliably trace a variety of foreign substances and contaminations – and gives you the assurance: In the next cycle too, the containers will only hold exactly what they are intended to hold.

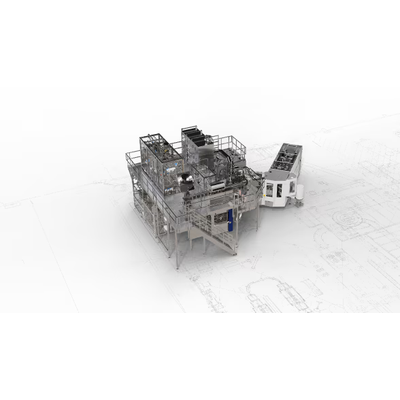

Krones - Model AseptBloc - Aseptic System

The Krones aseptic systems family includes experts for all kinds of different sterilisation methods and products to be filled. One of them is the Contipure AseptBloc. Regardless of whether you are blow moulding, filling or capping, with the Contipure AseptBloc every production step is safely included in an aseptic processing chain.

Krones - Model VarioStore - Tank System

The intermediate storage and buffering of products in the product treatment process is crucial for an effective and finely tuned production process. The Krones VarioStore range of sterile tanks includes versions with or without agitator and a tank volume of between 20 and 50 m³. The vacuum-tight tank is complemented by a valve manifold with aseptic product valves, sterile steamlocks and the necessary process gas feed.

Single Machines - Stretch Blow Moulder

Krones - Model Bloc BL - Stretch Blow Moulder Machine

Blocking a stretch blow moulder and labeller brings many advantages. And that is the reason why we have further perfected the combination of both machines in one block. With a seamless drive concept, finely tuned transfer interfaces for every production program and precisely operating processes in stop situations, you can count on getting the very best out of your PET bottle production.

Krones - Model BigBottle - Stretch Blow Moulder Machine

What is the main characteristic of the Contiform BigBottle? It`s obvious: "bigger and better". Whether we are talking about output per cavity, flexibility, efficiency or reliability - this blow moulder masters every challenge brilliantly.

Single Machines - Filling Systems

Krones - Model Bloc FS-C - Can Filler-Seamer Block Modulfill Machine

The Modulfill Bloc FS-C has already established itself on the market. Now Krones has further developed the block solution. The design incorporating an isolator is particularly suitable for companies that prioritize the highest standards of hygiene during can filling and have sustainability firmly anchored at the top of their corporate philosophy.

Krones - Can Seamer Modulseam Machine

Filler and seamer from one manufacturer – it goes without saying that this set-up only offers advantages both for the production as well as for the operators. This exactly is the reason why Krones placed its Modulseam can seamer on the market in 2017. In the meantime, the machine has proven itself in the field and is consequently also part of the Modulfill Bloc FS-C for cans.

Krones - Capping Technology

Beverage containers are used in various sizes and shapes worldwide and accordingly there is great diversity in container closures. With the Krones cappers, you can reliably apply all common cap types to containers.