- Home

- Companies

- Kuraray Group

- Products

Kuraray Group products

Plastics

Exceval - Water Soluble Resin

It is water soluble and can also be heat-melted and molded, EXCEVAL creates significant new possibilities for water soluble molded materials. After drying, membranes made from EXCEVAL are extremely durable, and it enhances the water resistance of adhesives and other materials.

Genestar - Highly Heat Resistant Polyamide Resin

GENESTAR is a proprietary polyamide resin developed by Kuraray. This synthetic resin is highly resistant to heat, water, and abrasion, yet easily molded. GENESTAR is widely used in connectors for electronic and electrical devices such as personal computers, digital cameras, and mobile telephones. In recent years, the development of GENESTAR auto parts has progressed, and we expect such applications to increase.

Chemicals, Elastomers and Rubber

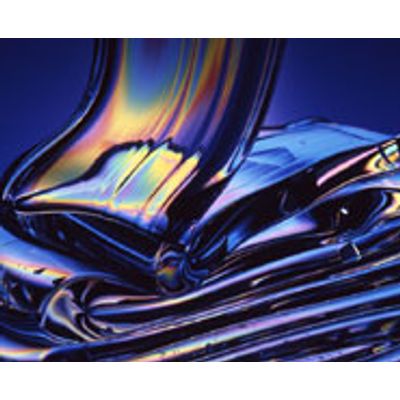

Kuraray - Liquid Isoprene Rubber (LIR)

LIR is a transparent, odorless liquid isoprene rubber. Having characteristics as a reactive plasticizer, LIR can soften rubbers when used in kneading rubber, in addition to acting as a cross-link with rubber when shaping it. The existing rubber plasticizer (mineral oil) degrades rubber`s properties by oozing, spoiling it in the shaping process. LIR, however, eliminates this problem. To that end, LIR is particularly appropriate for tires that require high performance.

Fabric, Manmade Leather, Nonwoven Fabric, Hook and Loop Fasteners

Kuraflex - Melt-Blown Non-Woven Fabric

Kuraray has developed a non-woven fabric with ultra-fine fibers using the latest melt-blow technology. It has excellent filtering capabilities, air permeability, and waterproofing functionality for use in coffee packs and food packaging, masks, filters, and exterior wall liner. Kuraray is developing new products that combine this fabric with other non-woven fabrics.

Other Products

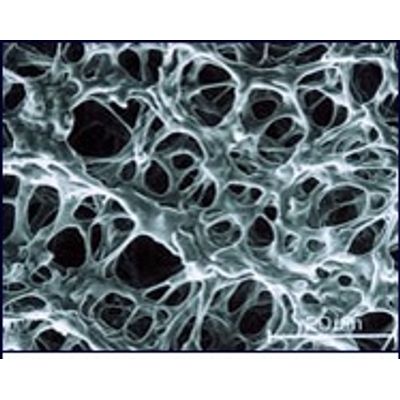

Kuraray - Gel Bioreactor

Excellent fluidity in water requiring minimal energy for mixing. PVA gel has a network of minute pores about 20 microns in diameter tunneling throughout each bead.