Lakeside Equipment Corporation products

Products - Screw Pumps

Lakeside - Open Screw Pump

The open screw pump consists of a spiral screw, upper and lower bearings and a drive assembly. It pumps liquid in a semi-circular open trough permitting both simplicity and reliability. These screw pumps can be placed in either concrete or steel troughs at an angle of inclination ranging from 22 to 40 degrees. The screw pump’s sealed lower bearing can be designed with a long lasting sleeve bearing and integrated grease lubricating system or a permanently greased lubricated roller bearing that can minimize maintenance. These self-aligning bearing assemblies are designed for continuous or intermittent operation in submerged or non-submerged conditions.

Lakeside - Enclosed Screw Pump

Enclosed Screw Pumps provide the same pumping capability as Open Screw Pumps but are encased within a tube rather than sitting in an open trough. Lakeside Equipment is the only manufacturer who offers two different types of Enclosed Screw Pumps.

Products - Raptor - Screening

Lakeside Raptor - Fine Screen

Unlike conventional bar screens, the RaptorFine Screen’s characteristic cylindrical screenings basket, angled installation and screen bars of varied heights increase removal efficiency and minimize headloss. The Raptor® Fine Screen’s rotating rake teeth fully penetrates the cylindrical screen bars, positively removing debris and grease to prevent blinding or plugging. Captured screenings are compacted, dewatered and washed free of most organic materials to approximately 40 percent solids. Volume is reduced by 50 percent and weight by 67 percent, resulting in reduced disposal costs.

Lakeside Raptor - Micro Strainer

Ideal for small treatment facilities, theRaptor Micro Strainer is a screen with a semi-circular basket with small apertures ranging from 0.04 to 0.25-inches (1 to 6 mm). It captures small debris that passes through other screens. A perforated plate or wedge wire basket is available for municipal or industrial applications. The captured screenings are washed, compacted, and dewatered to a dry solids content of 40 percent as they are transported up the inclined screw for disposal. This step reduces the volume by 50 percent and weight by 67 percent, ultimately reducing disposal costs.

Lakeside Raptor - Rotating Drum Screen

An excellent screenings solution for applications requiring removal of small particles, the Raptor® Rotating Drum Screen’s high removal efficiency meets the needs of Membrane Biological Reactor (MBR) designs. Using either a perforated plate or wedge wire basket with openings ranging from 0.02 to 0.25-inches (0.5 to 6 mm) this screen is ideal for either municipal or industrial applications. Captured screenings are compacted, dewatered and washed free of most organic materials to approximately 40 percent solids. Volume is reduced by 50 percent and weight by 67 percent, thereby reducing disposal costs.

Lakeside Raptor - Septage Acceptance Plant

Remove debris and inorganic solids from septage tanks, grease traps, sludge, leachate and industrial waste with the fully automated Raptor Septage Acceptance Plant (SAP). The heart of the SAP is the Raptor Fine Screen, which compacts and dewaters the captured screenings to a solids content of 40 percent. The screen’s rotating rake teeth fully penetrates the cylindrical screen bars, which prevents plugging and blinding from grease and small debris. This allows for faster unloading times to generate more revenue for your facility.

Products - Trash and Screen Rakes

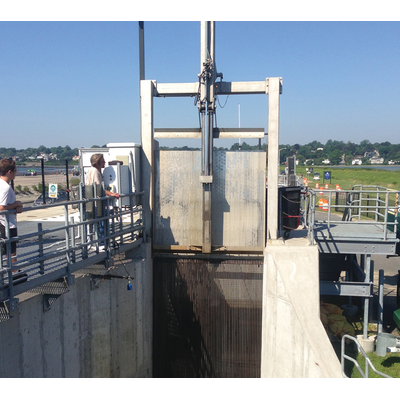

Lakeside - Hydronic Trash Rake

Clean bar screens, trash racks and intake screens at wastewater treatment plants, storm water facilities and water intake structures with Hydronic T Series Trash Rake. Telescoping designs are available with single and multiple sections to fit your operational needs. Since the rake mechanism is independent from the bar rack, the Hydronic T Rake does not require guides, sprockets or chains and has the ability to clean at rack inclinations up to 90-degrees. All moving parts can be accessed from above the channel for ease of operation and maintenance. Whether choosing the stationary or traversing rake, the Hydronic T can withstand the toughest applications plants have to offer.

Lakeside - Hydronic Trash Rake

Clean bar racks up to a depth of 100 feet with the hydraulically operated Hydronic K Series Trash Rake. The articulating design gives the rake arm a long reach suitable for manual surface skimming and removing large objects, such as trees, barrels and rootstocks. It is available as a stationary, swiveling or traversing unit providing the right fit for your operation.

Products - Grit Collection

Lakeside - Vortex Grit Removal System

Efficiently remove inorganic grit from the treatment plant in a mechanically induced vortex environment. The SpiraGrit® efficiently removes grit over a wide range of daily flow rates. Rotating paddles maintain the flow velocity in the vortex chamber, keeping organics in suspension while allowing heavier grit to settle on the chamber floor. The settled grit moves across the floor and falls into the lower grit hopper. A grit pump sends the captured grit from the lower hopper to a Grit Classifier or Raptor® Grit Washer for separation and dewatering. The grit pump can be either an airlift pump, self-prime pump or a recessed impeller pump.

Lakeside - Aeroductor Grit Removal System

The Aeroductor grit chamber effectively removes inorganic grit from the influent flow in a controlled, aerated environment. Air is injected into the grit chamber, circulating the contents and causing lighter organics to remain in suspension while heavier grit is scoured, washed and collected at the bottom of the tank. Settled grit is periodically removed by an airlift pump. The air-grit slurry mixture is lifted to the head box where the air is vented and the liquid/grit mixture is directed to the Grit Classifier for separation and dewatering.