Lightning Eliminators & Consultants, Inc. (LEC) products

Lightning Prevention & Lightning Safety

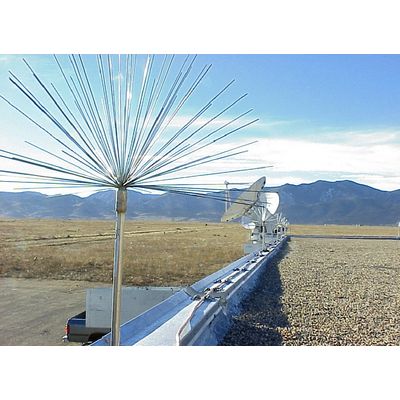

LEC - Spline Ball Ionizer (SBI)

LEC Spline Ball Ionizer (SBI) from Lightning Eliminators is a lightning protection design using a modular lightning prevention component to supplement Dissipation Array installations, and as the first line of defense for structures that require lightweight protection with a low wind profile. Like the Dissipation Array System (DAS), our patented SBI lightning protection technology greatly reduces the risk of direct lightning damage at the protected site.

LEC - Spline Ball Terminal (SBT)

The Spline Ball Terminal from Lightning Eliminators offers a superior alternative to standard air terminals for new or existing lightning protection systems. Unlike traditional lightning rods designed only to collect, the SBT is engineered to both reduce the risk of direct strikes and function as a highly efficient air terminal.

LEC - Streamer Delaying Air Terminal (SDAT)

The LEC SDAT from Lightning Eliminators offers an inexpensive alternative to standard air terminals for new or existing lightning protection systems. Unlike traditional lightning rods which are designed only to collect strikes, the LEC SDAT is designed to delay upward streamer generation, reduce the risk of direct strikes, and function as a highly efficient air terminal.

Storage Tank Lightning Protection

LEC - Retractable Grounding Assembly (RGA)

Floating Roof Tanks are always at risk from fires caused by lightning strikes. The award winning lightning protection design of the Retractable Grounding Assembly (RGA) reduces the risk of lightning damage and fire by creating a low-impedance bond between the roof and shell. The lightning protection design of the RGA 750 is cost effective, easy to install, and virtually maintenance free.

LEC - In-Tank Potential Equalizer

Charge Mitigation for Non-Metal & Lined Storage Tanks Containing Flammable or Combustible Liquids. The problem of internal electrical discharges and the subsequent ignition of the vapors inside tanks containing flammable or combustible liquids is becoming more widespread as the use of non-metal and lined tanks proliferates. These types of tanks are often used to store and separate the produced water and other products from hydraulic fracturing and other processes. Because these products can be highly corrosive, the tanks are often made of either corrosion resistant materials, such as fiberglass or PVC, or internally-lined steel, where the lining is a non-conductive material such as epoxy.