Linde Hydraulics GmbH & Co. KG products

Swashplate Hydraulic Displacement Pumps

Linde - Variable Displacement Pump

All the controls used in the Series 02 are based on a load-independent control mechanism. No matter which control is used: identical commands always result in the same response in the machine. The sensitive and precise machine control makes work easier and increases productivity. Various customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable control of the pump can easily be integrated into any kind of vehicle management control system.

Linde - Self-Regulating Displacement Pump

Legal emission regulations force manufacturers of mobile machinery to optimize the noise emission of their products. Since secondary measures tend to be expensive and less efficient Linde Hydraulics prefers to fight the noise where it is generated: by optimally connecting an additional volume directly next to the commutation of the HPR-02 pump, Linde Hydraulics invented the SPU silencer. The adaptive SPU reduces pressure pulsations in the regulating pump over the entire range of operation – without loss of power.

Axial Piston Motors

Linde - Variable Displacement Motors

Standard hydraulic motors at low speeds in their starting phase cannot generate the necessary torque. Therefore, the power of the fast spinning hydraulic motors has to be reduced by means of several step gearboxes down to the speed needed on the wheel. Somewhat higher windage losses and poorer mechanical efficiency are benevolently accepted in this context. Quite the opposite holds true for the motors by Linde Hydraulics: The motors of the Series 02 are capable of transmitting the required torque even at low speed and make it possible to start smoothly and sensitively.

Linde - Variable Displacement Double Motor

Hydro Variator for CVT

Linde - Integrated Pump / Motor Drive Units

Precise transmission control for simple operation without interrupting tractive effort. From stand still to maximum speed. Stepless. Together with the customer Linde Hydraulics defines new standards in technology. Advanced modular drive technology, realised in hydrostatic variators for variable speed transmission, form the core of power split gearboxes. Compact units with a hollow shaft are available for mounting to conventional gearboxes in smaller machines. These compact units are used as fully hydrostatic systems with PTO drive. With customer-specific developments, Linde Hydraulics supports the change from power shift to continuous variable transmission technology.

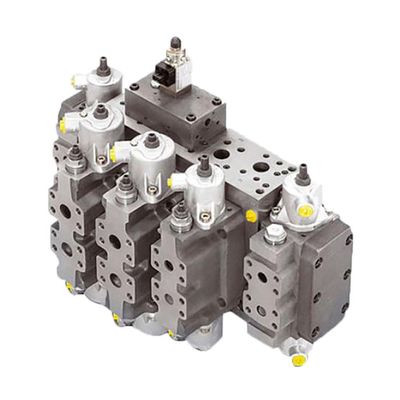

High-Pressure Valves

Linde - Main Control Valve

Linde - Main Control Monoblock Valve

Linde - Linde Synchron Control (LSC) Valve

LSC stands for high handling performance due to load-independent and sensitive machine conduct. Fast and direct. The Linde Synchron Control System, in open loop circuits, converts the commands of the machine driver into direct signals to the actuators. The easy control of all components supports efficient fatigue-free working. Simultaneous load-independent movements and a pump control ”on demand” are preconditions for fast working cycles with at the same time low operation cost. Safety and optimum exploitation of the machine are, apart from power regulation and high pressure relief, provided by the optional priority selection. Even with synchronous control of several functions the priority mode guarantees preferential operation of predominant actuators.

Electronics

Linde - Electronic Control Unit

Electronic control unit for open and closed circuit operations. Linde electronic control units of the iCon series feature high mechanic and electric robustness. Core components are a function controller and a safety control. Due to the redundant design, the unit can provide safety functions up to performance level d (DIN EN ISO 13849-1) and thus is able to meet global legal standards for on-road machinery. iCon controls are used individually or combined, for hydraulic and electric drives, as well as combinations of both. Additionally to the drive components, the combustion engine, as well as components such as sensors, joysticks and pedals can be integrated in the control system.

Linde LinTronic - Sensors

Electronic controls of the LinTronic Program take advantage of the most modern CAN-Bus technology. In conjunction with Linde hydraulic components and peripheral equipment the LINC electronic control units offer an optimum vehicle management in mobile hydraulics for the most diversified fields of application. By choosing economical modes of operation and increased user-friendliness they provide better exploitation of performance and at the same time reduce emissions.