- Home

- Companies

- Linn-Pumpen GmbH

- Products

Linn-Pumpen GmbH products

Gear Pumps

Linn - Gear Flange Pumps with Free Shaft End

Self-priming external gear pumps with mounting flange, compact pump housing in cast iron. Standard suction and pressure port: pipe thread (opposite 180°), for type F5.. SAE-flange optionally. mounting position variable

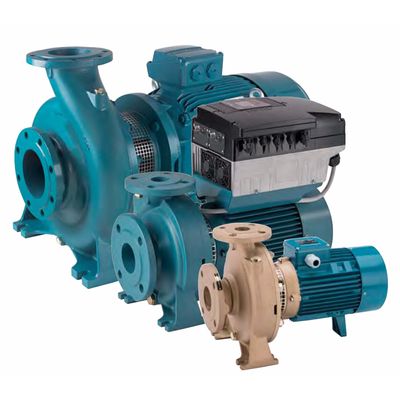

Centrifugal Pumps

Linn - Close Coupled Centrifugal Pumps with Flanged Connections

Close-coupled centrifugal pumps; electric motor with extended shaft directly connected to the pump up to 30 kW, new bracket construction for standard motors (stub-shaft construction) from 37 to 75 kW with integrated thrust bearing. Pump casing with axial suction and radial delivery on top, main dimensions and performance according to EN 733. NM(S): version with pump casing and lanter bracket in cast iron. B-NM(S): version with pump casing and lanter bracket/casing cover in bronze. (the pumps are supplied fully painted). Connections: Flanges according to PN 10, EN 1092-2. Counter-flanges (on request).

Linn - Close Coupled Centrifugal Pumps with Threaded Ports

Close-coupled, centrifugal pumps; electric motor with extended shaft directly connected to the pump. NM: single-impeller NMD: with two back-to-back impellers (with axial thrust balancing). Connections: threaded ports ISO 228/1 (BS 2779). NM, NMD: version with pump casing and lanter bracket in cast iron. B-NM, B-NMD: version with pump casing and lanter bracket in bronze. (the pumps are supplied fully painted).

Linn - Close Coupled Centrifugal Pumps with Flanged Connections

Close-coupled centrifugal pumps; electric motor with extended shaft directly connected to the pump up to 30 kW, new bracket construction for standard motors (stub-shaft construction) from 37 to 75 kW with integrated thrust bearing. Pump casing with axial suction and radial delivery on top, main dimensions and performance according to EN 733. NM(S): version with pump casing and lanter bracket in cast iron. B-NM(S): version with pump casing and lanter bracket/casing cover in bronze. (the pumps are supplied fully painted).

Linn - Centrifugal Pump with Open Impeller

Close-coupled centrifugal pumps with open impeller. Free-flow impeller (vortex or recessed impeller) for type C 16/1E. C: version with pump casing and lanter bracket in cast iron. B-C: version with pump casing and lanter bracket in bronze (the pumps are supplied fully painted).

Linn - Peripheral Pumps

Close-coupled peripheral pumps (regenerative pumps) with turbine impeller. T, TP: version with pump casing and lanter bracket in cast iron. B-T, B-TP: version with pump casing and lanter bracket in bronze (the pumps are supplied fully painted).

Linn - Horizontal Multistage Close Coupled Pumps

Horizontal multi-stage close coupled pumps in chrome-nickel stainless steel. Compact and robust construction,with compact lantern bracket and motor with feet. Single-piece barrel casing, with front suction port above pumps axis and radial delivery at top. Filling and draining plugs on the middle of the pump, accessible from any side (like the terminal box).

Flexible Impeller Pumps

Linn - Stainless Steel Flexible Impeller Pump

Self priming Pumps with flexible impeller are fast and easy to operate. Self priming AISI 304 and 316L stainless steel pumps with flexible impeller for thick and thin liquids. The main feature of these pumps is their strenght, due to the process throught which they are manufactured, that is to say stainless steel casting. The total absence of junctions or welding give to the material a high resistance to abrasion and corrosion. They feature thick walls (4-5 mm) and smooth surface. Mag pumps are suitable for whatever industrial sector and they are suitable for trasferring liquids gently without emulsifyng the product. Instant priming up to 4 - 5 meters. Pumping works in both directions of rotation. Suitable for thick liquids containing floating bodies. Mechanical seal is supplied according to the product to be pumped. The pumps are coupled to the electric motor in compliance with CE standard.

Linn - Stainless Steel Self-Priming Impeller Pump for Slow Running

The main feature of these pumps is their strenght, due to the process throught which they are manufactured, that is to say stainless steel casting. The total absence of junctions or welding give to the material a high resistance to abrasion and corrosion. They feature thick walls (4-5 mm) and smooth surface. Mag pumps are suitable for whatever industrial sector and they are suitable for trasferring liquids gently without emulsifyng the product. Instant priming up to 4 - 5 meters. Pumping works in both directions of rotation. Suitable for thick liquids containing floating bodies. Mechanical seal is supplied according to the product to be pumped. The pumps are coupled to the electric motor in compliance with CE standard.