Luoyang Ruichang Environmental Engineering Co., Ltd products

Process Burner

Ruichang - Low NOx Burner

Ruichang has more than 40 patented burner technologies, and the self-designed low NOx burner adopts fuel staging technology and decentralized combustion technology. At the same time, Ruichang has also carried out technical cooperation with Honeywell and its holding subsidiary UOPCallidus, adopting its advanced technology to produce low NOx burner whose NOx emissions are lower than the special emission limits of the Ministry of Environmental Protection.

Ruichang - Ultra Low NOx Burner

Ruichang ultra low NOx burner is designed for combustion systems in industries that rely on combustion processes such as traditional petroleum refining companies. In recent years, some countries or regions have formulated nitrogen oxide emission standards for special industries, requiring the chemical industry and refining industry to reduce the scale of nitrogen oxide emissions by 60%. Ordinary low-NOx burners can no longer meet the ultra low NOx emission requirements.

Sulfur Recovery Unit

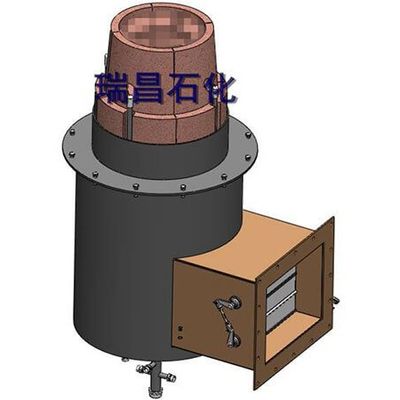

Heat Reaction Furnace

Under normal operation, the pressure in the reaction furnace is between 0. 04 – 0. 054Mpa and the temperature is between I 100 – 1400?. Generally, the acid gas in the reactor can reach its thermal equilibrium, and there is no need to add extra combustion fuel. The temperature of the furnace is governed by H2S contained in the fuel. Normally, 62%~70% of the Sx is created in the reactor, and the remaining is generated in the catalyzing reactor. The heat reaction furnace is the main equipment in the sulfur recovery unit. It plays various roles in different areas including ignition, automatic operation, deep reaction, and high-temperature edulcoration. So the reliable running of the heat reaction furnace is important for all units.