Lvfen Environmental Protection Tech. Co., Ltd.(LFEP) products

Filter

Lvfen - Automatic Pulse Bag Filter

The pulse bag filter is supported by a cage containing a Venturi tube, and a purge nozzle is arranged at the top of the filter bag. When working under normal conditions, the air flow from outside into the filter bags, and the dust is blocked on the external surface of the bags. During backblow, the pulse controllers open the electromagnetic pulse valve instantaneously, and the compressed air in the air manifolds is ejected from the purge nozzle. When passing through the Venturi tube, several secondary air is drawn in from the surrounding area and injected into the filter bags to purge the dust. Dust cleaning is carried out sequentially in row and does not affect the work of normal air flow. It is an online dust cleaning.

Lvfen - Basket Filter

Basket filter is a small equipment used to remove a small amount of solid particles in the liquid, it can protect the equipment normal operation, when the fluid enters filter cartridge with specific mesh size, the impurity is blocked outside, and the cleaned liquid exit from the filter outlet, when cleaning is required, dismantle the removable cartridge and reinstall it after treatment, therefore, it is very convenient in operation and maintenance.

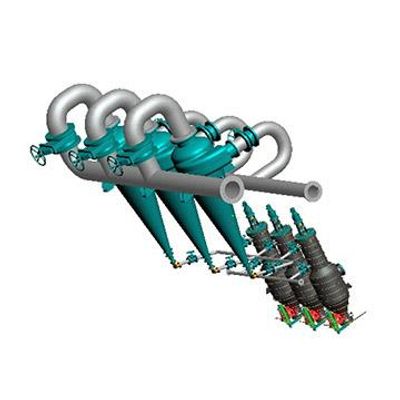

Lvfen - Residue Oil Cyclonic Filtration System with Dry Coke Discharge

In the residue oil cyclonic filtration system, the material goes downward with spiral movement via the cyclone, with the action of inertia centrifugal force, coke particles are thrown to the outer wall, with the down swirling flow to the bottom of the cone outlet, because the specific gravity of coke particles is greater than quench oil, the coke particles are drawn to the outer edge of the cyclone.

Lvfen - On-Line Automatic Backflushing Filter

Automatic backflushing filter mainly consists of high quality carbon steel or stainless steel vessel, stainless steel wedge wire mesh with special structure, water flow guide valve, differential pressure controller, control box and sewage discharge device, etc. It is suitable for the filtration and separation of liquid containing small particle solids. The filter has the advantages of simple operation and high level of automation. The filter elements could be cleaned online with long service life.

Other Filters

Lvfen - Filter Bag

As a filtration element, filter bag is a critical part in filtration, to some extent, the quality of filter bag plays a decisive role in the filtration performance. The filtration rating ranges from 0.5 micron to 300 micron, with material in polyester, polypropylene nylon etc., filter bag is suitable for use in various chemical liquid in paint, food, petrochemical, grain and oil, it is acid and alkali resistant, it could be repeatedly used for the high mechanical strength.

Lvfeng - PP Melt Blown Element

Melt blown element is made of PP non-tonic and odorless pellets, the tubular element is fabricated after melt, spin, pulling and molding. It is called PP melt blown element if the raw material is polypropylene. The element features in high precision, large flow rate, homogeneous structure, fouling holding capacity, long service life.

Cyclone

Lvfen - Cyclone

The cyclone can handle a large range of fluid flow capacity. Cyclonic separation is a method of removing particles from air, gas, or liquid streams by vortex separation without the use of a filter. Turbine effects and gravity are applied to separate solid and fluid mixtures. It can also be used to separate fine droplets from the airflow. In some cases, a cyclone could replace a vertical two-phase separator.

Gas Purification

Lvfen - Fresh Air System

Fresh air system is an independent air purification system consist of air supply system and air exhaust system, there are two types of fresh air system: duct and ductless fresh air system.

Gas Liquid Separator System

Lvfen - Gas Liquid Separator System

Gas Liquid Separator can separate impurities with high precision, coalesce and recover the separated materials, mainly used for processing the lubricating oil in the compressed air. The compressed air passes coalescing element in the separator, when the oil substances in gas pass through the layer of the filter element, they are first coalesced into larger oil droplets, which gradually fall to the bottom of the vessel under gravity, and the purified gas is discharged from the upper outlet. The effect of separator is good, the oil concentration could be reduced down to 5 ppm, it is a gas filter with ultra-high efficiency.