2 products found

Lvlogics products

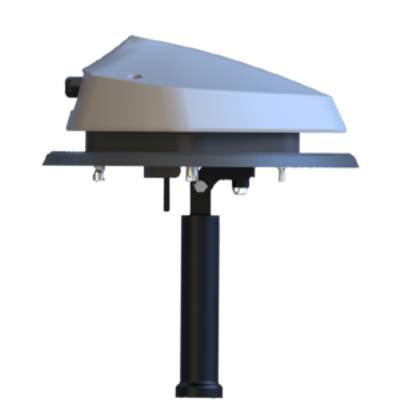

SiloSpi - The Pinnacle of Silo Monitoring Solutions

LvLogics introduces SiloSpi, an advanced silo monitoring system tailored for optimal performance in agricultural and industrial environments. This innovative system is designed to ensure uninterrupted supply management, enhance production efficiency, reduce operational costs, and promote a safer workplace. Equipped with a patented self-cleaning sensor, SiloSpi delivers precise, millimeter-level measurement accuracy, even in silos up to 40 meters in height. The sensor's unique self-cleaning feature prevents dust buildup, maintaining reliable readings under challenging conditions. The solution integrates IoT capabilities, transmitting continuous feed height measurements to a cloud platform. Users can access this data from any device to make informed decisions. SiloSpi operates without the need for SIM cards or Wi-Fi connections and supports various power options, including mains, battery, and solar. Designed for minimal calibration time, the system can be calibrated effectively over two fill and empty cycles. Alerts for low content levels can be configured for automated notifications and reordering.Industry

Lvlogics - Polymer and Plastics Silo Monitoring System

The Polymer and Plastics Silo Monitoring System leverages the advanced capabilities of the SiloSpi sensor to provide precise, real-time data on polymer raw material levels. This innovative monitoring solution enhances inventory management, reducing waste and improving the efficiency of plastics manufacturing facilities. The system features a self-cleaning, dust-penetrating laser sensor that is specifically designed to measure dusty materials such as plastics, ensuring reliable readings under challenging conditions. Installation and maintenance are simplified, resulting in minimal downtime. Additionally, the system supports remote access, enabling managers to monitor and manage silo levels from any location, ensuring optimal productivity and resource allocation. The versatility of the system allows it to handle a variety of polymer and plastic materials, making it a comprehensive solution for diverse manufacturing needs.