Maag Witte GmbH products

Shaft Seals

Double mechanical seal (DD)

The double mechanical seal with buffered fluid (DD) is suitable for a max. viscosity of 1.000 Pas, because the internal parts of the mechanical seal do not get in contact with the pumped fluid. All the internal parts are lubricated by the buffer fluid. The pressure on the suction side can be within a wide range: from vacuum conditions to max. 15 bar. Min. suction pressure: Vacuum, Max. suction pressure: 15 bar (psig), Max. temperature : 300°C (580°F), Viscosity: 0,2 to 1.000.000 mPas (cP).

Stuffing Box

The stuffing box is a simple seal for WITTE gear pumps. The operative range is similar to the viscoseal. It is suitable from low to high viscosities. The standard material for the packing rings is graphite (other materials are available). It is also available with buffered fluid and/or heating jacket.

Single Mechanical Seal (ED)

The single mechanical seal (ED) is the standard seal for WITTE CHEM pumps. It is suitable for max. viscosity of 10 to 50 Pas. Min. suction pressure: 1 bar (15 psig), Max. suction pressure: 15 bar (215 psig), Max. temprature: 300°C (580°F), Viscosity; 0,2 to 50.000 mPas (cP).

Vacuum Mechanical Seal (AD)

The single mechanical seal with buffered fluid (AD) in specially designed for vacuum conditions on the suction side. It is suitable for maximum viscosity of 100 Pas. Min. suction pressure: vacuum, Max. suction pressure: 5 bag (75 psig), Max. temperature: 250°C (500°F), Viscosity : 0,2 to 100.000 mPas (cP)

Gear Pumps

EXTRU - Model II b - Reliable Extrusion Gear Pump

The EXTRU is mainly used in conjunction with extruders or kneaders. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. The EXTRU is indispensable for the manufacture of precision films or micro granulate.

BOOSTER - Gear Pump for Polymer Processing

The reliable transfer and booster gear pump for polymer processing. BOOSTER gear pumps are used in the polymerisation process, to boost the pressure of medium to high viscosity media. They transport pre-polymers and polymers, e.g. PET, PBT, PS, ABS any many more, very gently Heating is either by way of heat transfer oil or steam. The core components like shafts and friction bearings originate from the WITTE building block system.

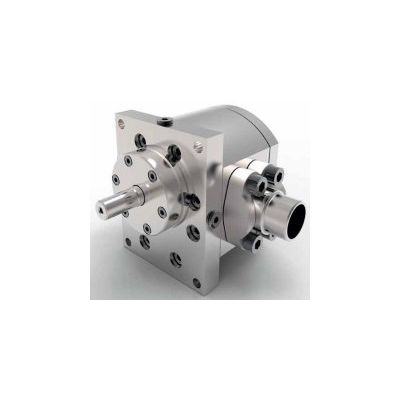

CHEM - High Precision Gear Pump for Conveying Low to Medium Viscosity Fluids

CHEM gear pump for conveying and metering of fluids with low medium viscosity. The application range goes from classic transfer and metering tasks in the chemical and pharmaceutical industries up to the conveyance of monomers, oligomers and prepolymers during the production of polymers. Decades of experience in construction and an optimum selection of materials, make this type of pump suitable for even the most demanding tasks and are outstanding in their reliability and metering precision in both vacuum and high pressure applications. Typical areas of application for this type of pump are to be found in the chemical, cosmetic, food, petrochemical and polymer industries.

Special Pumps

In additional to our standard pumps, we offer a wide range of special pumps, e.g. made of ceramic, tantalum, titanium or immersion pumps. Many of these pumps are custom built to suit the application in question and its specific operating parameters. WITTE for example produced on such pump, made completely of ceramic, for trasnporting a hoghly corrosive medium at temerature 550°C.

FOOD Pump - Stainless Steel Precision Gear Pump

Stainless steel precision gear pump for conveying and metering of fluids with medium to low viscosity. Through decades of experience in design and selection of optimal materials, this type of pump suitable for even the toughest of tasks and impresses with its reliability and metering accuracy in the vacuum as well as high-pressure applications. Typical areas of application for this type of pump are to be found in the cosmetic and food industries e.g. for conveying butter, margarine or vegetable oils. Pumps of this type can be supplied with or without heating (hydraulic or electric). The modular construction system for WITTE bearings, gears and shaft seals offers a maximum dimension of flexibility for the user. For better cleaning the pump has different flushing connections. An industry leading special design of this pump helps to minimize dead spots.

POLY - High-Pressure Discharge Gear Pump

POLY high-pressure gear pump for the discharge of medium to high viscosity media from the reactor. The extra large inlet opening guarantees an even flow of product to the gearwheels even under vacuum or extremely low NPSH conditions. Offered with either a round inlet port, by means of which the suction flange of the pump is directly connected to the outlet flange of the reactor or as a low NPSH version, where the pump is connected between the pump and reactor flanges, in order to achieve an even larger and shorter inlet port.