Magnetic Systems Internationial | MSI products

MSI - Suspended Permanent Magnets for Industrial Applications

MSI's suspended permanent magnets are designed for demanding industrial environments, providing solutions for separation and the removal of tramp metal. Ideal for conveyor belts with moderate load depths and speeds where electromagnets aren't necessary, these magnets are particularly effective in eliminating larger unwanted metal fragments that other separators might miss. Available in both manual clean and self-cleaning options, MSI's suspended magnets offer an economical choice for infrequent tramp material while ensuring continuous operation in environments with high tramp material frequency through self-cleaning mechanisms. Offering various strengths and sizes, these magnets can be customized according to specific industrial requirements, including various suspension and drive configurations. MSI also provides free testing services to help customers make informed decisions based on their unique application needs.

MSI - Suspended Electromagnets for Conveyor Systems

MSI's suspended electromagnets are engineered for settings that require a stronger magnetic field due to factors like suspension height, belt speed, or specific customer needs. These magnets are integral for protecting downstream equipment in conveyor systems, including crushers, bark hogs, and conveyor belts. Each electromagnet features oil-filled construction, advanced anodized aluminum coils, expansion tanks, and solid core construction for optimal durability and performance. Only premium-grade components such as bearings, motors, and reducers are used to ensure minimal downtime and extended service life. Available in manual clean and self-cleaning varieties, these electromagnets can be mounted cross-belt or in-line with conveyor belts. For those opting for self-cleaning units, MSI offers a variety of belting and drive system options. The power supplies, designed for global compatibility, come with multiple cabinet and voltage input choices. MSI provides free testing of customer samples and custom solutions for non-standard applications. Notably, the anodized aluminum coils come with a 10-year warranty against burnout.

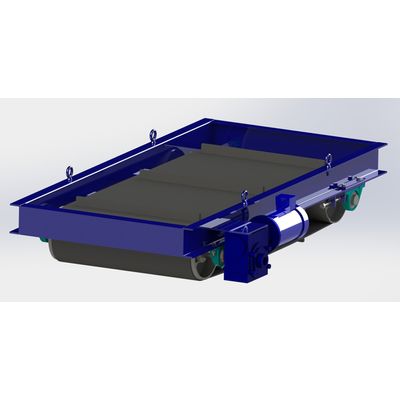

MSI - Magnetic Pulley Separators for Conveyor Systems

MSI's magnetic pulley separators serve as an efficient solution for magnetic separation and tramp protection within conveyor belt systems. Utilizing existing conveyor mechanics, these pulleys hold ferrous materials against the belt, allowing non-ferrous materials to continue their normal trajectory. As the pulley rotates, the ferrous materials are carried until they are discharged at the point where the belt separates from the head pulley. MSI's magnetic head pulleys offer comprehensive magnetic coverage from the bottom of the burden, complementing overhead magnetic separators that cover from above. These pulleys also function as rollers in magnetic conveying applications, effectively transferring steel and other ferrous materials. MSI provides the option to customize pulleys for particular applications, including separating different types of magnetic materials—a valuable feature for recycling operations. Customers can take advantage of MSI’s free testing services to identify the necessary pulley specifications, ensuring informed decision-making and confident purchases.

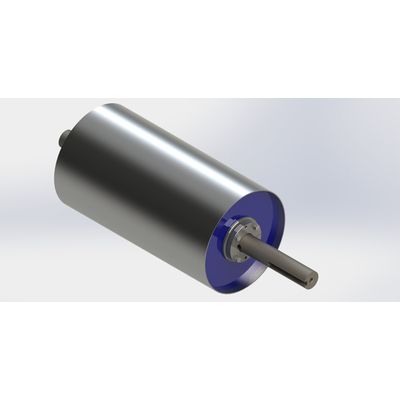

MSI - Drum Separators for Magnetic Separation

Magnetic Systems International (MSI) offers advanced drum separators designed for efficient magnetic separation of ferrous and non-ferrous materials. The system processes the product through a housing where it encounters the rotating drum. This outer shell rotation facilitates continuous cleaning of the magnet system, ensuring effective separation. Non-magnetic materials fall into a ferrous-free zone, while magnetic materials cling to the drum until they are discharged into a ferrous collection area. Drum separators are available in two main types: drum-in-housing magnets and drum-only magnets. The drum-in-housing design suits operations requiring integrated systems with continuous cleaning, while drum-only magnets are ideal for applications involving existing chutes, end-of-pulley placements, or vibratory conveyors. The drum separators come in radial and axial configurations, both offering behavior similar to magnetic head pulleys but with additional advantages. Technical data sheets and product specifications are accessible for detailed understanding and evaluation.

MSI - Grate Magnets for Fine Separation and Free-Flowing Dry Solids

MSI’s tubular magnetic circuit forms the core technology for numerous solutions in fine separation and free-flowing dry solid applications. It leverages magnetic elements to create robust, evenly distributed magnetic fields within stainless steel tubing. Multiple tubes can be combined for enhanced coverage, whether for small or large areas. This circuit is integral to products like grate magnets and drawer-in-housing units, and extends to pneumatic and hydraulic solutions like bullet magnets and T-Traps. The tubular magnetic circuit can use different tubing thicknesses to improve durability or performance. Customers can select between ceramic and rare earth magnet elements to meet varied strength and temperature requirements. Standard configurations employ 1” diameter stainless tubes within heavy-duty stainless steel frames, though custom configurations are also available. MSI’s drawer-in-housing units are particularly effective for removing ferrous contamination in dry processing, utilizing multiple offset rows of magnetic tubes to maximize contact and separation. Cleaning options range from manual to EZ-Clean to fully automated self-cleaning, catering to different volumes of tramp metal and operational requirements.