Mahr Maschinenbau Ges.m.b.H. products

Mahr - Model MM 2MM - Screen

The first of MAHR MASCHINENBAU´s latest developments in screening technology, the MM2MM screen, was installed in Austria in the summer of 2009. It is the first screen worldwide with a minimum bar-space of 2mm and raking combs made from stainless steel penetrating the screenfield. It is also the only fine bar screen complying with all international standards for hydraulic steelwork, such as continuous welding to avoid fissure corrosion (a serious problem for stainless steel constructions) and dimensioning based on stress-calculations designed to withstand three times the maximum water-pressure. It is suitable for channel-widths up to 4m and almost unlimited channel-depths up to 80m.

Klaerabella - Sludge Dewatering Drum

MAHR MASCHINENBAU´s KLAERABELLA is a mobile sludge-dewatering-drum designed especially for smaller sewage treatment plants. It can easily be moved and operated by one person. The operation is simple but highly efficient: The ratio capacity/efficiency can be adjusted simply by changing the drum´s inclination angle and rotation speed. The dimensioning is according to the client´s needs!

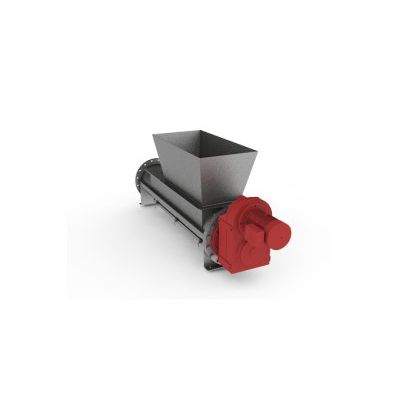

Mahr - Model RV - Screw Type Compactor

MAHR MASCHINENBAU´s Screenings Compactors RV are screw-type compactors, including a shafted screw with a reduced pitch in the compaction-zone. The last 360° flights of the screw are reinforced to 36mm thickness. The body of the compactor is made from stainless steel, the screw from high-tensile steel-alloy or also from stainless steel. A unique feature of our MM RV compactors are extra chambers on the motor-side of the trough, equipped with scraper-blades, to guarantee sufficient drain even if the trough´s perforation in the compaction-zone is blinded.

Mahr - Model RV - Wash Pactor

MAHR MASCHINENBAU´s Screening Compactors RV are also available in an upgraded version to reduce the organic content of the screenings: The Washpactor-RV. It includes a special washing-zone between inlet-hopper and compaction-zone. A disc, integrated into the cover of the trough, contains an assembly of beam- and fan-high-pressure nozzles to wash out organics and break up faecal matter. An additional high pressure pump to optimize the efficiency can be added. A plc-controlled forward-reverse operation crates a superb performance.

Mahr - Model MM SK 800 - Sand Classifier

MAHR MASCHINENBAU built the biggest sandclassifiers in the world: The MM SK 800, installed at the main sewage treatment plant in Vienna. These giants are equipped with 800mm-diameter-screws and handle the sediments of a plant with a hydraulic flow of 24m3/sec. Also available in smaller sizes!

Mahr - Sand Washer

In order to reduce the organic load of the sand and grit collected by the MM SK, MAHR MASCHINENBAU designed her own sandwasher, the MM SW. Following our philosophy to design custom-made products, your MM SW will be built especially to your needs. The flow rate and the expected volume of grit will determine the size, and you will have full flexibility in respect of wash-water amount, timing of the cleaning cycles, discharge duration and intervals. This will guarantee that the MM SW will fully meet your expectations.

Mahr - Hand Operated Sluice Gates

MAHR MASCHINENBAU´s penstocks range from hand-operated sluice-gates to plate sizes of 5 x 5m and 47m water-pressure. Our penstocks are mainly made from stainless steel, have electric or hydraulic actuators and emergency hand-operation. They have three- or foursided seals, water pressure can be on- or offseal. In any case, the penstocks will be custom-designed for your needs. Design-calculation based on finite-elements-method will guarantee an optimized ratio between maximum safety and minimum material and operation costs.