MARCH PUMPEN GmbH & Co. KG products

Magnet Drive Centrifugal Pumps

March - Model M1 Series - Non Metallic Magnet Drive Centrifugal Pumps

PERFORMANCE DATA: Flow: max. 8 l/min. Head: max. 4 mwc. TEMPERATURES: PP: max. 70°C. POM: max. 90°C. Noryl: max. 90°C.

March - Model MCH 40-32 Series - Non Metallic Magnet Drive Centrifugal Pumps

PERFORMANCE DATAS: Flow: max. 17,5 m³/h. Head: max. 22 mwc. TEMPERATURE: PP: max. 70°C. PVDF: max. 90°C.

March - Model MP-6R to MP-120RT Series - Magnet Drive Centrifugal Pumps

Performance Datas; Flow: from 8 / 9 up to max. 220 l/min (50/60Hz). Head: from 1 / 1,4 up to max 10,5 mWs (50/60Hz).

March - Model M4 SS - Magnet Drive Centrifugal Pumps

Performance Data; Flow: max. 51 l/min. Head: max. 4,8 mwc. Temperatures; Stainless steel: max. 100°c.

Magnet Drive Chemical Pumps Acc. to DIN 24256 - EN 22858

March - Model Series MCA - Metallic Magnet Drive Chemical Pumps

Performance Datas: Flow: 8 - 200 m³/h. Head: max. 90 mwc.

Magnetic Driven Gear Pumps

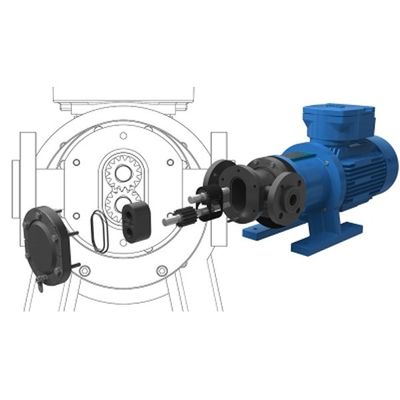

MARCH - Model TEF-MAG 200 - Magnetically Coupled Gear Pumps

MARCH Series TEF-MAG pumps are rotating positive displacement pumps, external gear type and magnetically coupled. TEF-MAG gear pumps generate low flows with high discharge pressures and approximately no pulsation. The pump housing is made of resistant solid block plastics like PP or PVDF. The internal hydraulic parts are made of non-metallic materials. The power transmission of drive and pump happens in a contactless way with firm NdFeB or SmCo permanent magnets. So the pump is able to work without any shaft seals, which guarantees save supplies without any leakage of corrosive, toxic and explosive fluids. Pumps for potentially explosive areas in zone 1 and 2, can be made out of PVDF.

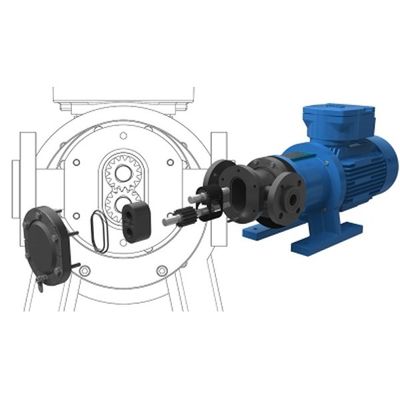

MARCH - Model TEF-MAG 3500 - Magnetically Coupled Gear Pumps

MARCH Series TEF-MAG pumps are rotating positive displacement pumps, external gear type and magnetically coupled. TEF-MAG gear pumps generate low flows with high discharge pressures and approximately no pulsation. The pump housing is made of resistant solid block plastics like PP or PVDF. The internal hydraulic parts are made of non-metallic materials. The power transmission of drive and pump happens in a contactless way with firm NdFeB or SmCo permanent magnets So the pump is able to work without any shaft seals, which guarantees save supplies without any leakage of corrosive, toxic and explosive fluids. Pumps for potentially explosive areas in zone 1 and 2, can be made out of PVDF.