Master Pneumatic Inc. products

Filters - General Purpose Filters

Master Pneumatic - Model FD10 - Sentry Modular Filters 1/8, 1/4 and Tube Fittings

Modular assembly and mounting. Threaded ports or quick-connect fittings for tubing up to 10 mm in diameter. 5-µm-rated polyethylene ?lter element; optional sintered bronze elements. High-strength polycarbonate plastic ?lter bowl; optional aluminum bowl. Internal automatic drain; optional manual drain. NPTF port threads; optional BSPP threads.

Regulators - General Purpose Regulators

Master Pneumatic - Model CX-0 and CX-1 - Miniature CO2 Regulator 1/8 and 1/4

Inline mounting. Avaliable in relieving and non-relieving diaphragm designs. Outstanding control at a relatively low cost. Pressure gauge optional. NPTF port threads; optional BSPP threads.

Lubricators - Lubricator Function

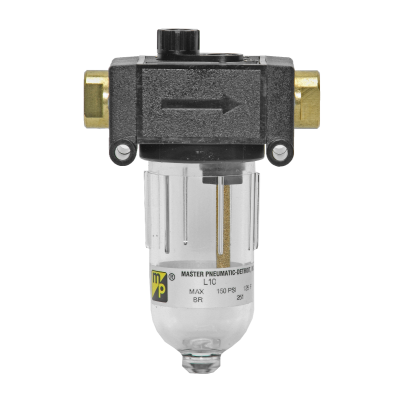

Master Pneumatic - Model L10 - Sentry Modular Wick-feed Lubricator 1/8 and 1/4

The L10 Sentry Modular Wick-Feed Lubricator offers precise lubrication designed for compressed air applications. Its modular assembly allows easy configuration with either threaded ports or quick-connect fittings to accommodate tubing up to 10 mm in diameter. The lubricator features a wick-feed design and is constructed with durable materials like acetal for the body and a 2-ounce polycarbonate plastic bowl, with an optional aluminum bowl for increased robustness. It operates in ambient and media temperatures ranging from 40° to 125°F and can handle a maximum inlet pressure of 150 psig. The external oil adjustment feature allows for precise control without requiring a shutdown. This lubricator is compatible with NPTF port threads, with BSPP threads available as an option. The seals used are made from Nitrile, ensuring durability and reliability under various conditions, making it suitable for industrial use where consistent and reliable lubrication is needed.

FRL Assemblies - Integral CFRL Combinatios

Master Pneumatic - Model VCFDRL10 & 11 - Modular Air Treatment System for Industrial Applications

Master Pneumatic offers a modular air treatment system that integrates filters, regulators, and lubricators within a consolidated assembly, specially designed for precision and customizable configurations. The air treatment units are constructed with durable materials such as acetal and features automatic or manual draining options. The filtration system is equipped with different filter elements, including polyethylene and sintered bronze, rated at 5, 20, or 40 microns, to ensure optimal particle removal from compressed air. The system supports an inlet pressure range of 15 to 150 psig and provides adjustable outlet pressure up to 100 psig, suitable for diverse industrial applications. Modular connectivity allows for easy installation via threaded ports or quick-connect fittings. Polycarbonate or aluminum bowls are available with a capacity of 60 ml, featuring options for internal automatic or manual drains. The regulators employ either piston-type or diaphragm-type mechanisms for precise control. Optional dome and knob configurations enhance usability for engineering professionals.

Precision Lubrication - Single Point Lubricators - SPL

Master Pneumatic - Model A60 & A64 - Serv-Oil Upstream SPL (Single Point Lubricator) for Air Tools 1/2 and 3/4

SERV-OIL SINGLE POINT UPSTREAM LUBRICATOR:The single-point lubricator (SPL) is speci?cally designed to lubricate air tools. It cannot be used for general lubrication of components other than air tools. An SPL is installed in the air supply line upstream of the air tool. When the tool is cycled the SPL injects a precise amount of oil at the air inlet of the tool. Both the amount of oil and the frequency of injection are adjustable.