Memsift Innovations Pte Ltd. products

Stomate - Hydrophobic Hollow Fiber Membrane

For efficient thermal membrane separation process, the membrane should ideally exhibit several optimum characteristics in terms of membrane thickness, membrane porosity, membrane pore size, chemical and thermal stability, membrane surface chemistry (hydrophobicity) and high liquid entry pressure (LEP). We have a highly hydrophobic hollow fiber membrane with unique surface chemistry for vapor and steam transportation called Stomate.

Memsift - Zero Liquid Discharge (ZLD) System

TS-30 is a Zero Liquid Discharge (ZLD) system in which 100% water and the valuable resources(products, acid, salts and precious metals) can be recovered. As there is zero discharge at the end, the process will also help to reduce the environmental impact.

Brine Treatment for Zero Liquid Discharge

Galvanizing industries, electroplating industries, semiconductor industries, metal processing industries, chemical industries, pharmaceutical industries, oil & gas industries and many other industries generate high saline wastewater. The recycling rate in these industries are < 20%. Conventional treatment processes (chemical and biological) does not remove salinity. Reverse osmosis is the well-known technology to treat saline wastewater however; it is limited with salt concentration in the feed water due to osmotic strength. Moreover, it is always a challenge to treat/dispose the RO rejection/brine/high strength wastewater. Disposing the rejection back to the sea / sewer is another environmental issue that needs to be addressed. Conventional distillation and evaporation methods are too expensive. Inexpensive, environmental friendly technologies are critical for brine treatment and zero liquid discharge (ZLD).

Memsift - Technologies for Saline Wastewater Treatment and Zero Liquid Discharge

Galvanizing industries, electroplating industries, semiconductor industries, metal processing industries, chemical industries, pharmaceutical industries, oil & gas industries and many other industries generate high saline wastewater. The recycling rate in these industries are < 20%. Conventional treatment processes (chemical and biological) does not remove salinity. Reverse osmosis is the well-known technology to treat saline wastewater however; it is limited with salt concentration in the feed water due to osmotic strength. Moreover, it is always a challenge to treat/dispose the RO rejection/brine/high strength wastewater. Disposing the rejection back to the sea / sewer is another environmental issue that needs to be addressed. Conventional distillation and evaporation methods are too expensive. Inexpensive, environmental friendly technologies are critical for brine treatment and zero liquid discharge (ZLD).

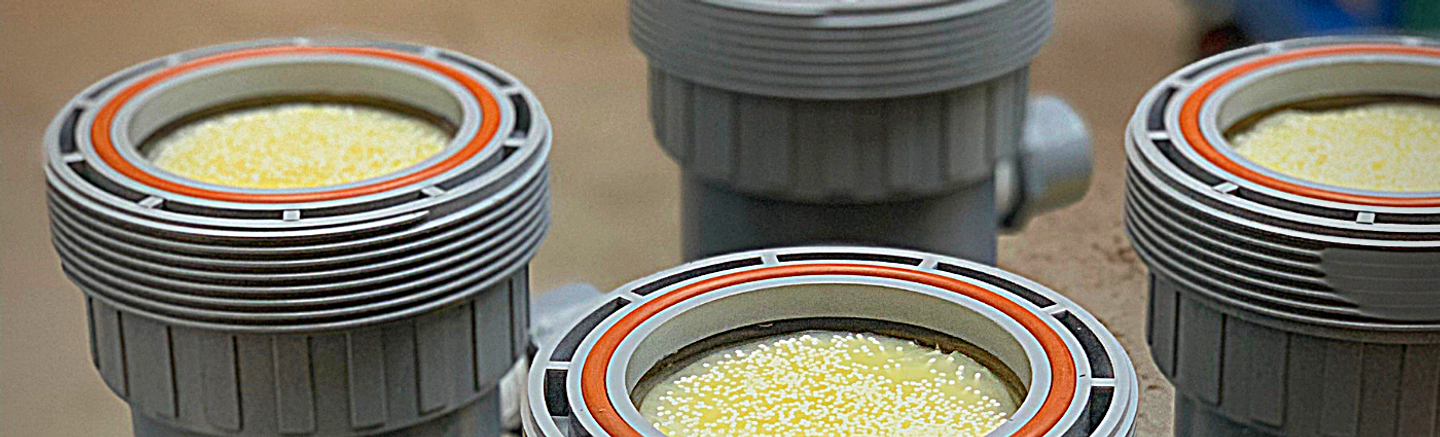

Memsift - Membrane Distillation Module

Memsift’s TS-30, SL series modules are designed and developed based on an innovative thermal membrane process for pharmaceutical, chemical and F&B industries. The SL series module consist of specially designed chemical and solvent resistant highly hydrophobic hollow fiber membranes. The module housing is made up of thermoplastics. Memsift supply membrane modules in various sizes from 4 inch diameter to 8 inch diameter. The TS-30 module has designed to achieve very high permeate flow at lower temperature. The SL series modules can be used for liquid-liquid and liquid-solid separations

Memsift Stomate - Membrane Distillation Module

Memsift’s TS-30 modules are designed and developed based on an innovative thermal membrane process. The TS-30 module consist of our proprietary highly hydrophobic hollow fiber membrane STOMATE®. The module housing is made up of thermoplastics. Memsift has developed membrane modules in various sizes from 2 inch to 8 inch diameter. The TS-30 module has designed to achieve very high permeate flow at lower temperature. The modules can be used for liquid-liquid and liquid-solid separations like Membrane Distillation.

Memsift - Zero Liquid Discharge System

GRAVITY is a new generation crystallizer that works in the principle of gravitational force/centrifugal force and temperature difference. It requires very low energy consumption (at least 50% energy reduction) compared to the current state of the art crystallizers. The unit is made up of thermoplastics that eliminate corrosion issues while handling the concentrated brine. The simple and modular design helps for easy installation, operation and maintenance. The concentrated brine from the TS-30 system will be channeled to the crystallizer to achieve zero liquid discharge.

Hollow Fiber - Membrane Distillation Technologies

Memsift’s TS-30 modules are designed and developed based on an innovative thermal membrane process. The TS-30 module consist of our proprietary highly hydrophobic hollow fiber membrane STOMATE®. The module housing is made up of thermoplastics. Memsift has developed membrane modules in various sizes from 2 inch to 8 inch diameter. The TS-30 module has designed to achieve very high permeate flow at lower temperature. The modules can be used for liquid-liquid and liquid-solid separations like Membrane Distillation.