Meri Environmental Solutions GmbH products

Water Treatment - Fresh Water

Meri Dino - Coarse Screening

The DINOSCREEN is a travelling screen for industrial applications. This machine has a sturdy construction for accessibility and maintenance, especially designed for paper mills. The DINOSCREEN removes coarse contaminants and drifting material from mill sewer U-drains or freshwater water intake channels.

Meri - Circular Sedimentation and Flotation System

The circular sedimentation series is based on the experience of hundreds of successful running installations in industrial and municipal applications. Modular 3D design enables our circular sedimentation to be custom-designed to suit your specific requirements offering you perfect economical and technical solutions.

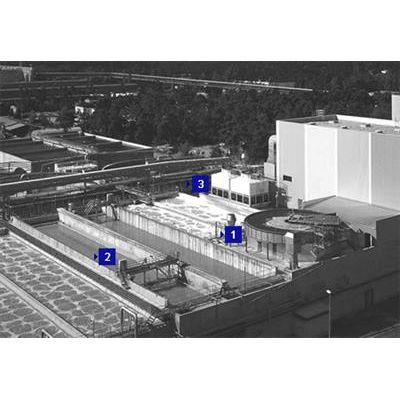

Gyroblock - Filtration System

The GYROBLOCK is a concrete module for sand filtration applications. Due to the modular design, it can handle high volumes of freshwater. It features a specially designed feed distribution for homogeneous inflow distribution. Main advantages: Continuous operation, no down time for back-washing, integrated continuous regeneration of sand.

Water Treatment - Waste Water

Meri - Primary Treatment System

Currently, most of all effluent treatment plants are designed as a combination of multiple stages combining chemical, physical, and biological treatment stages. Depending on the requirements for final discharge quality, many different concepts and technologies can be applied.

Meri - Anaerobic Treatment Plant

Anaerobic processes are used for the treatment of higher loaded effluents. Anaerobic bacteria in the form of biopellets are used for the conversion of dissolved COD in to methane (biogas). In the paper industry anaerobic technology is mainly used in board and packaging mills. Other industries with high COD loaded effluent such as breweries or dairies can also benefit from the advantages of this technology:

Sludge Handling

Meri - Large Sludge Quantity Plant

Sludge in the paper industry represents a large amount of residual material generated by stock preparation plants and paper mills. It is often comprised of many streams, Such as DAF sludge, flotation rejects, fine screen rejects and forward cleaners. Employing proper sludge pre-thickening and post thickening strategies maximizes the dryness of the disposed material. Achieving high dryness values while maintaining high solids capture rates minimizes the process impacts and costs associated with handling this by-product.

Blue Press - Small Sludge Quantity Plant

The BLUE PRESS Series is a line of belt presses specially developed for dewateringand thickening of primary and secondary sludge. Their design makes themsuitable for different sludge characteristics and biological sludge content. The gravity area, installed prior to the wedge and pressing area, allows for thetreatment of sludge even at low consistency. The application of pressure rollstogether with the specially designed pressure pattern area achieve a highdryness even for sludge with low structural material content.

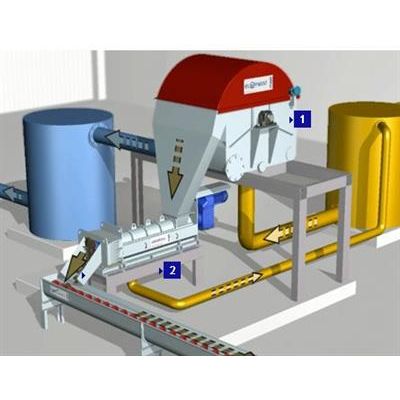

Meri - Sludge Pressing Plant

After dewatering, mechanical pressing usually achieves the highest possible final dry content at the lowest possible disposal costs (based on weight). In the case of thermal recycling, for example, the highest calorific values can be achieved because of the lower moisture content. State-of-the-art screw presses have prevailed over belt filter presses in high dry content dewatering. Screw press advantages at a glance:

Waste & Recycling

Compax - Compacting Plant

Handling of rejects in order to achieve an effective separation into different reject categories in accordance with increasingly stringent laws is a must for up-to-date technology for reject handling. Thanks to the experience of numerous installations, we are able to design the most appropriate reject handling to suit your requirements for new production lines as well as upgrading your system.

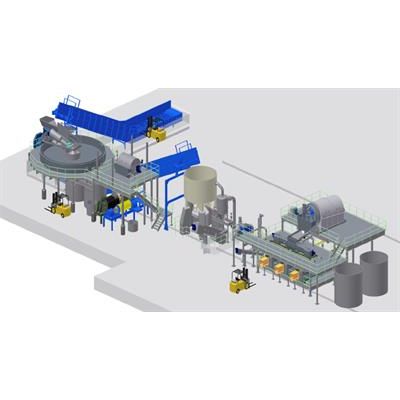

Meri - Plastic, Waste, Fuel Recycling Plant

Difficult to recycle polyethylene sources create a broad range of feed stocks for composite manufacturing plants. Our comprehensive system technology has made this concept an economical as well as an ecological success.