Mesa ETP, by MESA Industries, Inc products

Storage Tank Products - Emission Reduction Products

Mesa ETP - Floating Roof Seals for Tank Products

Floating roof seals are essential components in floating roof tanks, designed to control emissions and minimize the loss of stored products. Mesa ETP offers various types of primary and secondary seals suitable for diverse applications. Primary seals include mechanical shoe seals and resilient filled seals like liquid-filled tube seals and foam log seals. Mechanical shoe seals, known for their superior lifespan, employ Best Available Control Technology and can be installed 'in-service'. Channel Hanger seals are cost-effective for standard applications, while Compression Shoe seals address tanks with out-of-roundness. Secondary seals, necessary for external floating roofs, may also be mandated if the primary seal is vapor mounted. These include long-lasting compression plate seals and lower-profile Duo-Tip wipers. Mesa ETP provides diverse configurations, enabling optimal seal selection for specific requirements.

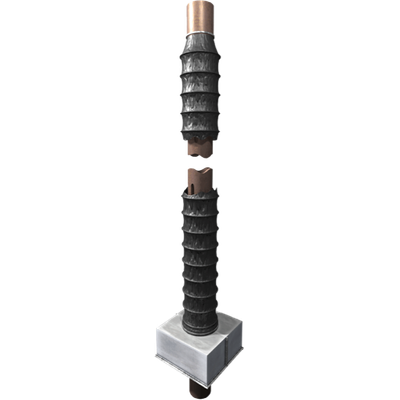

VAPOR-GUARD - Gauge Pole Cover

The VAPOR-GUARD® VT Gauge Pole Cover is designed to reduce emissions from aboveground storage tank slotted gauge poles / guide poles. Tank owners benefit by reducing product loss while meeting environmental regulations. Mesa ETP engineers and fabricates each gauge pole cover according to specific installation conditions within tank parameters. VAPOR-GUARD® VT gauge pole cover is field-tested and approved, featuring over 10 years of proven performance. All covers are manufactured in the USA within a Quality Management System (QMS) that is ISO 9001:2015 certified. The VAPOR-GUARD® VT gauge pole cover “flexible enclosure system” is approved by the US Environmental Protection Agency (EPA) as stated in the Storage Tank Emission Reduction Partnership Program (STERPP). This program allows a “flexible enclosure device that completely encloses the slotted guide pole and a cover on top of the guide pole.”

Storage Tank Products - Flexible Pipe Systems

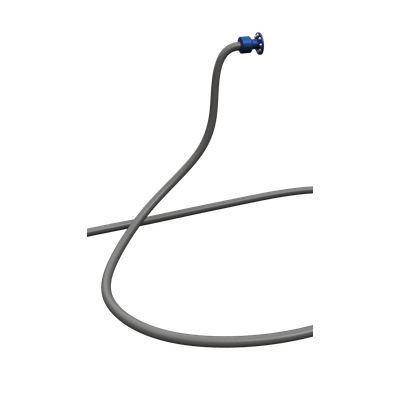

Mesa ETP ARMOR-CLAD - Flexible Roof Drain System

Mesa ETP ARMOR-CLAD Roof Drain systems are specialized for ensuring efficient water drainage from floating roofs of aboveground storage tanks. These systems are custom-engineered to match specific tank dimensions and local rainfall data, featuring compatibility with a wide range of pH solutions and chemicals. They boast a durable design with a historical lifespan of over 20 years if installed and operated correctly. The system's design eliminates horizontal movement and potential damage by utilizing a repeating lay pattern coil that rises and lowers predictively with the roof level. Constructed in a single continuous length, ARMOR-CLAD® avoids flow restrictions caused by joints or corrugations, facilitating high flow rates. The negative buoyancy of the flexible pipe is a key feature for different storage mediums, and its stainless steel armor ensures protective integrity. These attributes make it ideal for applications such as skimmer and foam delivery systems. The installation involves comprehensive tank analysis and accurate engineering documentation, ensuring optimal performance.

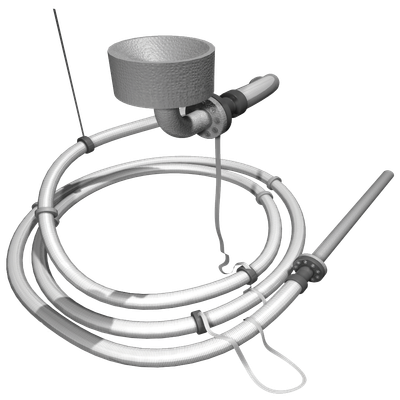

Resist-All-Clad - Advanced Storage Tank Emission Reduction and Control Solutions

Mesa ETP RESIST-ALL-CLAD® Roof Drain systems ensure drainage of water from the aboveground storage tank’s floating roofs. Mesa ETP Roof Drain systems are engineered to suit customer tank dimensions and rain fall data. Mesa ETP RESIST-ALL-CLAD® Roof Drain systems are engineered for continuous service in a wide range of pH solutions and chemicals. It is completely compatible with pure M.T.B.E., 100% aromatic hydrocarbons (Benzene and Toluene), pure alcohol, gasoline and jet fuels. Mesa ETP RESIST-ALL-CLAD® assemblies are historically proven to last over 20 years provided the system is sized, installed and operated in the intended service. Mesa ETP RESIST-ALL-CLAD is engineered and manufactured as a true flexible drain system with repetitive lay pattern (multiple coil). This design will not undue force on the floating roof. The whole assembly is designed and manufactured in a single continuous length with no intermittent joints or couplings to restrict flow. Mesa ETP RESIST-ALL-CLAD® features a tether system that keeps the drain in position as installed. Tethers are attached to the underside of the floating roof and between ballasts on the flexible pipe.

Storage Tank Products - Specialty Engineered Tank Products

Mesa ETP - Floating Roof Pontoon Repair Liners

Mesa ETP custom designs floating roof pontoon repair liners pontoon liners for floating roof storage tanks. Mesa ETP floating roof pontoon repair liners are inserted into floating roof pontoons that have taken on liquid from the storage tank. The pontoon liner is installed inside the pontoon and inflated to displace product and keep the roof afloat. Mesa ETP’s floating roof pontoon repair liners are most commonly used in pontoons that have begun to leak. Leaking pontoons can fill with product from the tank causing the floating roof to sink. Sunken roofs can cause a range of undesirable situations in the tank. The floating roof can be severely damaged if it sinks into the product. A sinking roof can damage the shell and floor of the tank. Floating roof pontoon repair liners provide additional buoyancy to pontoons, allow for stabilization of the floating roof, help prevent sunken roof, avoid tank and roof damage, avoid environmental hazards or violations, and avoid costly cleanup and decontamination procedures.