- Home

- Companies

- Metal Engineering

- Products

Metal Engineering products

Metal Engineering - Model DS VERTEX - Disc Screen

DS VERTEX disc screens are high-performance equipment for screening raw materials, including for automatic separation of organic fractions from household and commercial waste, separation of large foreign objects from the general material flow.

Metal Engineering - Model DHM - Hammer mill

The hammer crushers of the DHM series are intended for grinding of loose, brittle and fibrous materials, with a fraction up to 50 mm, such as biofuels, wood processing wastes (chips, shavings, bark), animal feed, biomass, etc. These durable, highly efficient hammer crushers come as standard and optionally with optional nodes to handle non-standard waste processing tasks.

Metal Engineering - Model OS - Oscillating Screens

OS oscillating screens are solution for sifting bulk materials (sand, chalk, limestone, dolomite, etc.), sawmill waste such as wood chips, sawdust, wood chips (animal bedding), bark, cable waste (plastic cleaning after vibrating tables), crushed plastics, up to 400 kg / m³ with particle sizes up to 100 mm (random inclusions up to 500 mm). Also, OS oscillating sieves are indispensable when sifting bulk foods (flour, starch, sugar, wheat, corn, soy, etc.). If necessary, all surfaces in contact with the material are made of stainless steel. FUNCTIONAL DESIGN OS oscillating screens are completed with easily replaced thick steel nets. Depending on the task, the meshes are made of perforated or mesh meshes with a variable wire diameter, which is necessary for the exact classification of materials.

Metal Engineering - Model SM - Screening Machine

SM screening machines are designed to extract small copper fraction (copper dust, thin copper wires) from cable waste, which remains in the crushed cable insulation after the main stages of separation. Also, these machines are used to sort and calibrate various bulk materials (crushed plastics, grain, seeds, oats, corn, lentils, etc.) The powerful steel construction together with the screening deck made of duralumin ensure a long service life even under difficult conditions. The equipment is completed with replaceable double grids, which inside contain rubber balls for automatic cleaning of grids from material that litters the cells during operation. Features of SM screening machines: the deck is equipped with an outlet for connecting aspiration; frequency converters for fine tuning of the process; parts manufacturers, electric motor NORD (Germany), SKF (Sweden), FAG (Germany). increase the service life of the main process equipment;

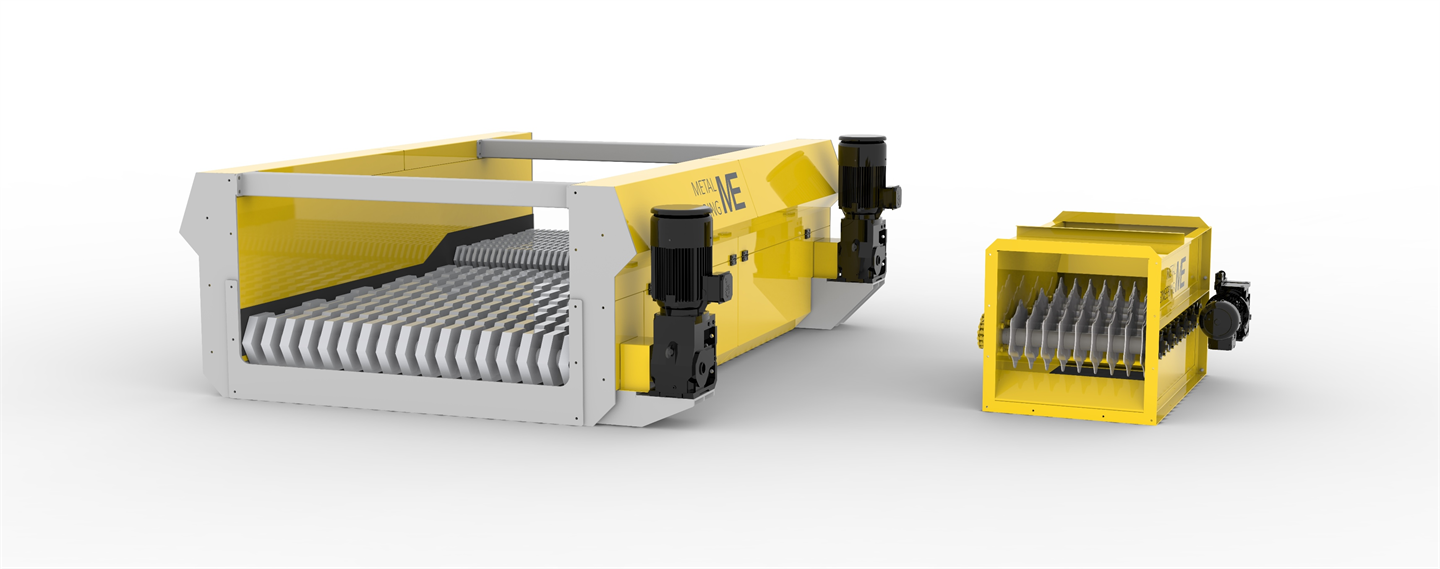

Metal Engineering - Bag Breaker

Bags breaker is a high-performance equipment for the automatic opening of garbage bags, which eliminates the need for manual opening. The material in the bags is fed to the breaker using a belt conveyor for uniformity. Drums that rotate in opposite directions effectively open the bags and release the contents, which are unloaded from the bottom of the machine onto a belt conveyor. The design is easy to use and can be used for municipal solid waste (fraction up to 300-400 mm), organic waste, mixed materials in bags, waste paper in bags. Depending on customer requirements, it is completed with conveyors for loading and unloading material.

Metal Engineering - Model FS - Doser For Solid Matter

Dosers for solid matter FS are designed for the accumulation and dosing of solid substrates (corn silage, grass silage, bird droppings, sugar beet pulp, etc.) to the fermenter of a biogas plant or equipment downstream. A key feature of doser for solid matter FS is the price / quality. This type of installation is ideal for biogas plants, where the solid matter substrate - corn silage.

Pushfloor For Discharging Materials

The mechanized storage PUSHFLOOR is intended for accumulation, agitating, storing and uniformly dosing the biomass with up to 70% humidity (shredded wood waste, technological and fuel chips, bark, pellets, husks, brewing and alcohol waste, agricultural products, chicken litter, etc.).