- Cutting - Abrasive Cutting

- Cutting - Precision Cutting

- Mounting - Hot Mounting

- Mounting - Cold Mounting

- Grinding & Polishing - Planar Grinding

- Grinding & Polishing - Modular Grinding & Polishing

- Grinding & Polishing - Advanced Grinding & Polishing

- Grinding & Polishing - Grinding & Polishing Systems

- Grinding & Polishing - Electrolytic Preparation

Metkon Instruments Inc. products

Cutting - Abrasive Cutting

Metcut - Abrasive Cutting Machine

Microprocessor controlled, front panel with touch-pad controls, compact powerful 3 kW motor, electronic brake system, cutting capacity up to 115/90 mm solid stock, for cut-off wheels up to Ø300/250 mm, twin T-slotted clamping table 255x250 mm made of stainless steel, bottom part as rugged alloy base casting, ABS protective hood, Ready for operation. Without clamping devices, without recirculation cooling tank. 400 V, 3 phase, 50 Hz. Includes a standard set of cutting consumables composed of; 1 pack of medium type 10 cut-off wheels 250 mm dia. 1 pack of medium type 10 cut-off wheels 300 mm dia. 5 lt of METCOOL cooling fluid.

Cutting - Precision Cutting

MICRACUT - Precision Cutter

Modern touch-pad controls with digital display, ergonomic turn knob for fast and easy setting of parameters, 100 W powerful DC cutting motor, variable speed 0-1000 rpm, with digital micrometer cross feed for specimen positioning, counterbalanced sliding weight system, removable cooling unit, automatic cut-off switch, transparent protection hood with magnetic safety switch, for cutting discs of up to 150 mm diameter. Ready for operation. Without specimen vises. 230 V, 50 Hz, AC. Includes a standard set of cutting consumables composed of; *1 pc. Diamond cutting Disc 150 mm dia. *1 lt of METCOOL II cooling fluid.

Mounting - Hot Mounting

ECOPRESS - Automatic Mounting Press

Fully automatic operation with microprocessor controls, electro hydraulic pressure (requires no air), with touch pad front panel controls and digital display of; heating time, moulding temperature, cooling temperature, ram up/down, auto/manual cooling, cycle start/stop. Last parameter settings retained in the memory, with ergonomic turn knob for fast and easy setting of parameters, with direct reading pressure gauge, moulding pressure up to 300 bar, temperature up to 2000C, operation time up to 35:00 minutes, short cycle time, thermostatically controlled heating power of 1650W, automatic cooling cycle, programmable slow cooling feature, stand-by temperature, selectable mould sizes from 25 mm to 50 mm, easy to close bayonet closure, audible warning signal, ready for operation. 230 V, 1-phase, 50/60 Hz. Mould assemblies are ordered separately. Includes a standard set of mounting consumables composed of 3 different hot mounting compounds; 1 kg of each and a total of 3 kg.

Mounting - Cold Mounting

VACUMET - Cold Mounting

Self-contained vacuum impregnation unit. With built-in pneumatic vacuum system of -0.65 bar, vacuum gage and one set of supplies for casting epoxy resins. Includes a standard set of mounting consumables composed of 10 cups, 10 silicon tubes, 10 wooden mixing spoon 2 scale tubes.

Grinding & Polishing - Planar Grinding

Forci Plan - Planar Grinding Machine

For initial planar grinding of metallographic specimens in specimen holders, bench top compact design, closed housing, max. safety provided with interlocking switch, robust column mounted in taper roller bearings, low noise with motor of 2.2 kW and 2800 rpm, easy handling with manual sample swing movement from the front side of the machine, ergonomic vertical precision positioning of the grinding head with an accuracy of 0.01 mm, large working space with LED lamp, standard outlet for dust exhauster, complete and ready for operation. Standard packing included. Sample cooling available with cooling fluid. Without clamping devices. Without cooling tank. 400V, 3-phase, 50 Hz. Includes a standard set of grinding consumables composed of; *1 pc. 150 mm. Dia. Al2O3 Cup Grinding Stone for ferrous materials *5 lt of METCOOL cooling fluid.

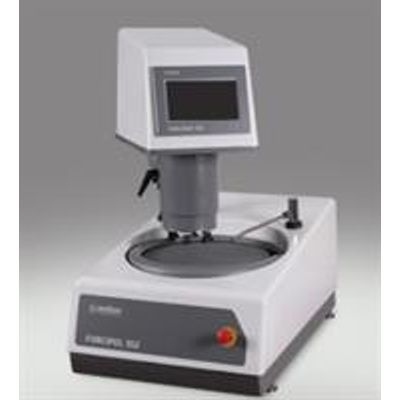

Grinding & Polishing - Modular Grinding & Polishing

Forcipol - Grinding and Polishing Machine

Single wheel, suitable for 200, 250 and 300 mm wheel size, 0.75 kW motor with overload protection, variable speed between 50-600 rpm, clockwise or counterclockwise rotation, soft start and stop function, vibration-free and robust construction, ergonomic design, quite operation, standard interface for all head units (FORCIPOL Control Unit and FORCIMAT 52/102/TS), retractable water hose, including water supply and drain tubes. (One of the Head Units is required to operate the equipment).

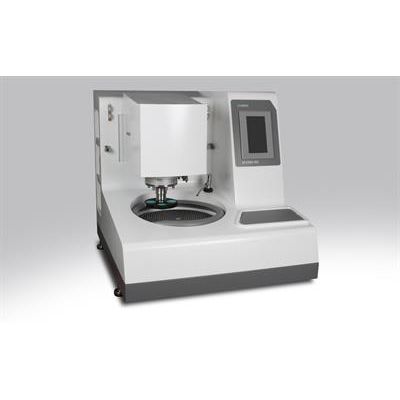

Grinding & Polishing - Advanced Grinding & Polishing

ACCURA - Advanced Grinding & Polishing

Powerful Preparation System with solid frame design on two columns, for superior surfaces, for a very wide range of applications from very coarse grinding to very fine grinding and polishing, suitable for 250 mm as well as 300 mm dia. applications, programmable sample preparation with colored 7" HMI touch screen control, with Siemens PLC control unit. Base Unit with large 1.5 HP motor, with overload protection, variable wheel speed from 50 to 750 rpm, quite belt drive, vibration-free and robust construction, Soft Start/Stop, planar grinding feature, Complementary or Contra rotational direction, retractable water hose, water supply and drain tubes.

Grinding & Polishing - Grinding & Polishing Systems

VELOX - Grinding & Polishing Systems

Fully automatic programmable grinding and polishing system. Fast, precise and operator-free sample preparation for high volume sample throughput, with 4 stations (1 coarse grinding, 1 fine grinding and 2 polishing), Fully automatic sample cleaning station with water and ethanol, Hot air drying station with timer, Independent grinding & polishing stations with 1,5 HP powerful motor, Comp. or Contra rotational direction, Soft Start /Stop, Suitable for both 250 mm and 300 mm applications, Variable wheel speed ; 100 - 1200 rpm for coarse grinding, 50 - 600 rpm for fine grinding and polishing stations, programmable sample preparation with colored 10" HMI touch screen control with Siemens PLC control unit, Head movement automatically proceeding from one station to the other with servo driven motor.

Grinding & Polishing - Electrolytic Preparation

ELOPREP - Electrolytic Polishing & Etching System

Automatic and programmable electrolytic polishing and etching of metallographic specimens, with Siemens PLC control unit, user friendly colored 7" LCD touch screen controls, short polishing times and maximum reproducibility, separate polishing unit equipped with drain pipe and integrated cooling system, dual Polishing & Etching units operatable by the same control unit, optional external etching unit, 0-100 V output voltage for polishing, 0-25 V for etching and 0-15 V for external etching. Variable polishing time and current, with current limitation, built in safety features with continuous control of electrolyte, scanning function for easy determination of parameters, variable speed controlled pump with magnetic stirrer for electrolyte flow. Suitable for both normal and low temperature electrolytic polishing. Ready for operation. Includes 1 pc. of stainless steel cathode.